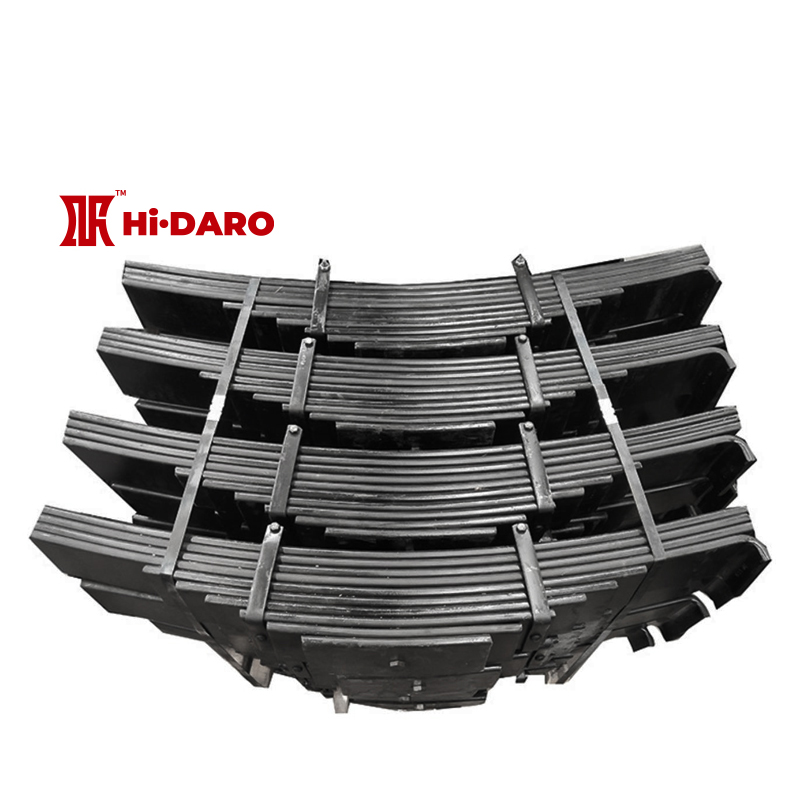

Trailer leaf springs

Trailer leaf springs For American Type Suspension Parts bought wholesale by using DARO Group have the traits of sturdy rigidity, excessive load-bearing and dependable performance. It is the most broadly used elastic element in automobile suspension. It consists of countless portions of equal width however now not equal size (thickness can be equal, thickness can be equal, thickness can be equal). Can additionally be no longer equal) alloy spring plate aggregate of an approximate equal power of the elastic beam, the shape is simpler, convenient to set up and use, upkeep and substitute greater convenient, cost-effective.

Material: rear leaf spring

Surface treatment: shot blasting

Working form: stretching

Height: 5-45 (mm)

Brand: DARO

Products Description

High elasticity—— Leaf Spring For American Type Suspension Parts are particularly elastic, in a position to face up to a giant wide variety of deformations and return to their unique form and dimension when exterior forces are removed.

High load capacity—— Due to the excessive stiffness of Leaf Spring For American Type Suspension Parts, it can stand up to a massive quantity of load barring everlasting deformation.

Good stability—— Leaf Spring For American Type Suspension Parts have desirable balance and will now not exchange significantly with modifications in the exterior environment.

Corrosion resistance—— Leaf Spring For American Type Suspension Parts after exclusive anti-rust treatment, corrosion resistance is strong, can additionally play a steady overall performance in harsh environments.

1, multi-blade spring: By a quantity of portions of length, the equal width of the metal sheet stacked together. The metal plates of a couple of leaf springs are stacked into an inverted triangle shape, the longest metal plate at the pinnacle and the shortest metal plate at the bottom, the variety of metal plates is associated to the weight of the aiding bus, the thicker and shorter the metal plate, the larger the pressure of the spring.

2, much less blade spring: with the aid of the two ends of the skinny center thick, equal width and size of the metal sheet stacked together. The metal plate area of the small leaf spring adjustments greatly, and the part from the center to the two ends is progressively different, so the rolling technique is greater complicated, and the rate is greater luxurious than the multi-leaf spring. Compared with multi-blade springs, beneath the equal stiffness (that is, the equal carrying capacity), the much less blade spring is about 50% lighter than the multi-blade spring, which reduces gas consumption and will increase trip comfort.

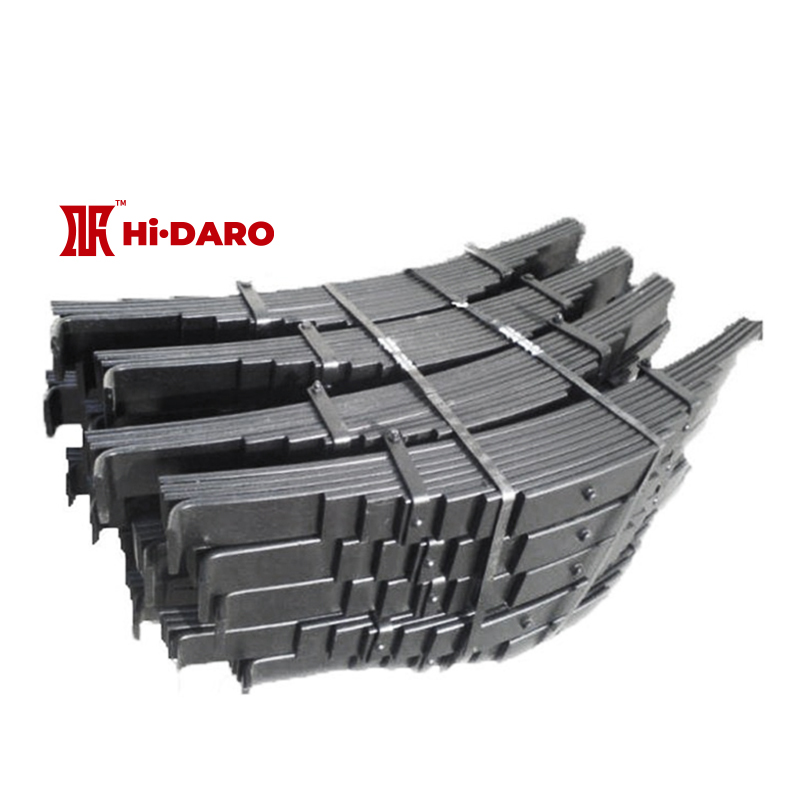

Application Scenario

Trailer leaf springs is easy in structure, dependable in operation, low in value and handy in maintenance. It is now not solely the elastic issue of suspension, however additionally the information machine of suspension. One give up is hinged with the frame, which can transmit a number of forces and torque and decide the beat trajectory of the wheel. At the identical time, it additionally has a sure friction damping effect. It can kill three birds with one stone, so it is extensively used in more than a few sorts of non-independent suspension.

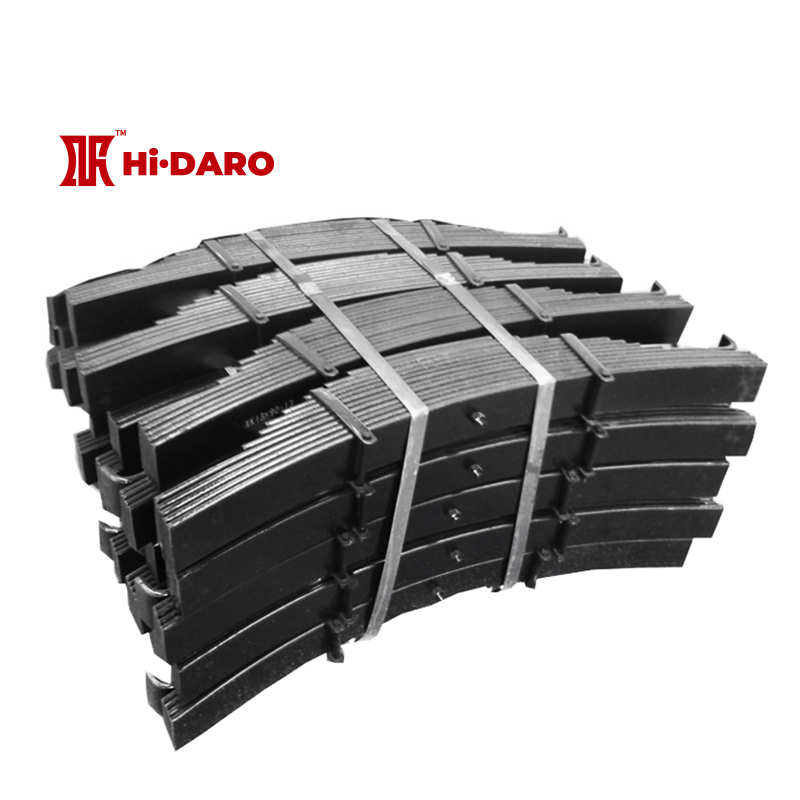

Package & Delivery