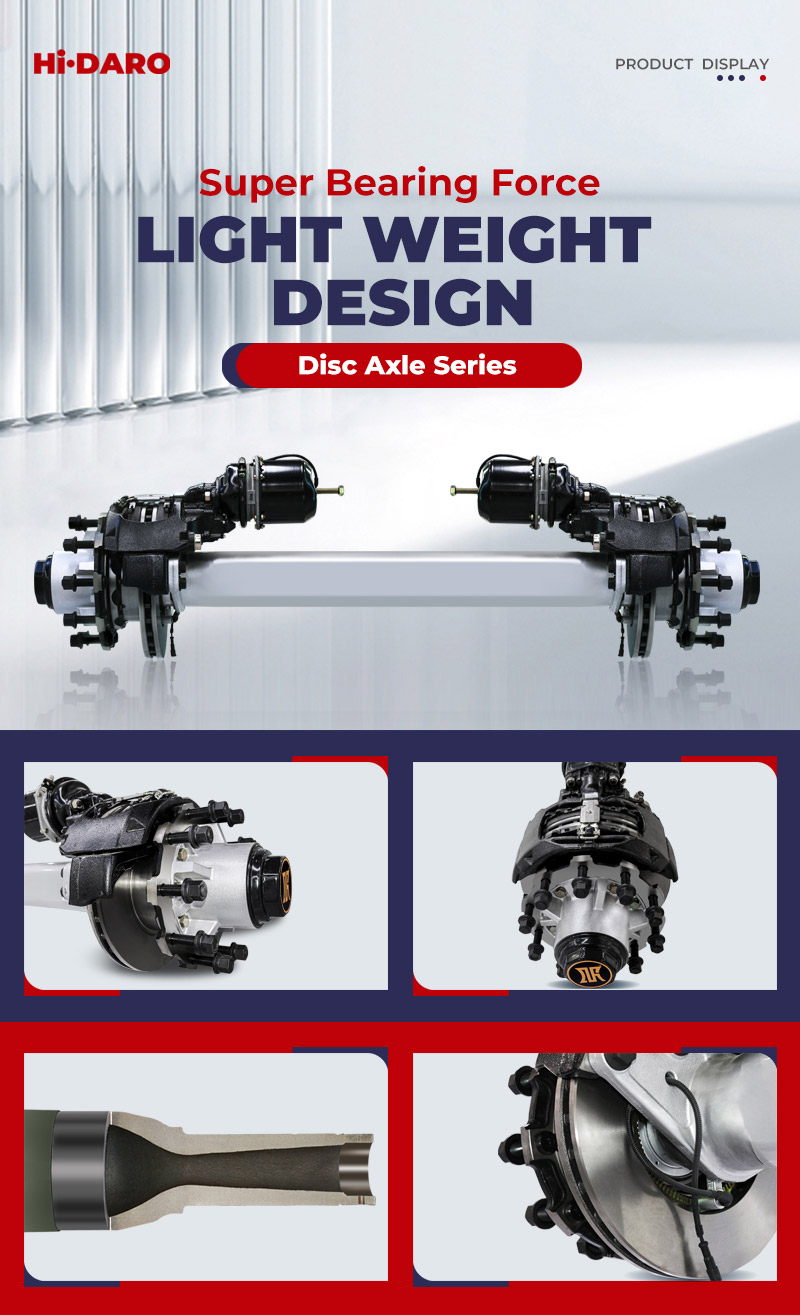

Semi trailer disc axle

Disc brake trailer axles:

1. Better raw materials

The Darong axle is made of 20Mn2 high-strength alloy seamless steel pipes with a wall thickness of 10-11mm. Compared to ordinary steel pipes, they have better tensile strength, yield strength, impact toughness, and other properties, and are not prone to cracks during processing and use.

2. Accessories selection

The accessory brands used by Darong Axle have been deeply cultivated in the industry for many years, and their quality has been baptized and tested by the market, with corresponding quality assurance capabilities. In addition, Darong also needs to carry out a series of quality inspection procedures on it, which can only be put into use after passing the inspection, which is equivalent to providing an additional layer of quality assurance.

3. Custom production

In order to meet the different tonnage, track width, parameters, and other requirements of users in the axle field, Darong has launched a customized axle service, which designs drawings based on the actual use needs of customers, and then carries out customized production. Accessories such as hubs, brake drums, bearings, and other accessories can also provide a variety of options.

Axle load(T):13

Brake(mm):430*45

Offset(mm):120

Tire:20"/22.5"

Products Description

Disc brake trailer axles,developed and manufactured by Daro Group, the first vehicle bridge enterprise in the Liangshan Special Purpose Vehicle Production Base to mass produce integrated axles, the axle body and axle head are polished and formed on the same high-strength alloy steel pipe, which is superior to the welded axle head in terms of heavy load performance. Fifteen production processes strictly comply with industry standards, coupled with online and offline dual quality inspection, and the product quality is rigorous and up to standard, fully meeting the user's use needs.

| Model | Offset (mm) | Axle load | Brake (mm) | Wheels Installed | Tire |

| DRP09 | 120 | 9 | 377*45 | 10/280/335/M22*1.5 | 19.5"/20/22.5 |

| DRP09 | 0 | 9 | 377*45 | 8/220/275/M22*1.5 | 19.5" |

| DRP09 | 9 | 377*45 | 8/220/275/M22*1.5 | 19.5" | |

| DRP11 | 11 | 377*45 | 8/220/275/M22*1.5 | 19.5" | |

| DRP09 | 120 | 9 | 430*45 | 10/280/335/M22*1.5 | 20"/22.5" |

| DRP09 | 0 | 9 | 430*45 | 10/280/335/M22*1.5 | 20"/22.5" |

| DRP09 | 9 | 430*45 | 10/280/335/M22*1.5 | 20"/22.5" | |

| DRP11 | 0 | 11 | 430*45 | 10/280/335/M22*1.5 | 20"/22.5" |

| DRP11 | 11 | 430*45 | 10/280/335/M22*1.5 | 20"/22.5" | |

| DRP13 | 13 | 430*45 | 10/280/335/M22*1.5 | 20"/22.5" |

Compared to traditional drum brakes, disc brakes have significant advantages in sensitivity, heat dissipation, thermal degradation resistance, and performance recovery after wading. When used in conjunction with air suspension and hydraulic retarders, they can greatly improve the safety and stability of vehicles and cargo.

Application Scenario

Disc brake trailer axles was first introduced into the market in 2018 and has undergone multiple updates and iterations, featuring light weight, strong bearing capacity, fast heat dissipation, convenient maintenance, and long maintenance cycles.Disc brake trailer axles can be widely used in transportation conditions with high requirements for cargo damage, such as semi hanging of three-axis fence, transportation of dangerous goods, transportation of precision instruments, transportation of valuables, and transportation of flowers, fruits, and vegetables.

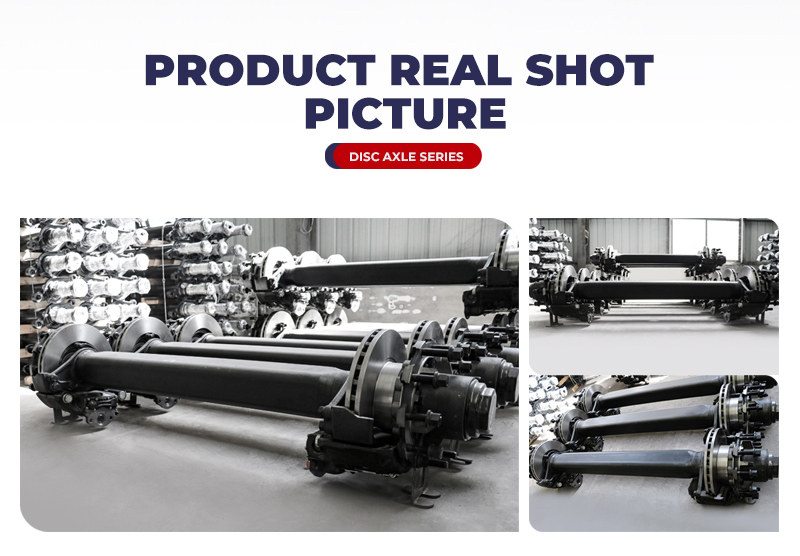

Package & Delivery