Disc brake trailer axles

Disc brake trailer axles lightweight design super load-bearing capacity

Lighter weight

——using lightweight materials and accessories, full fuel saving and efficiency.

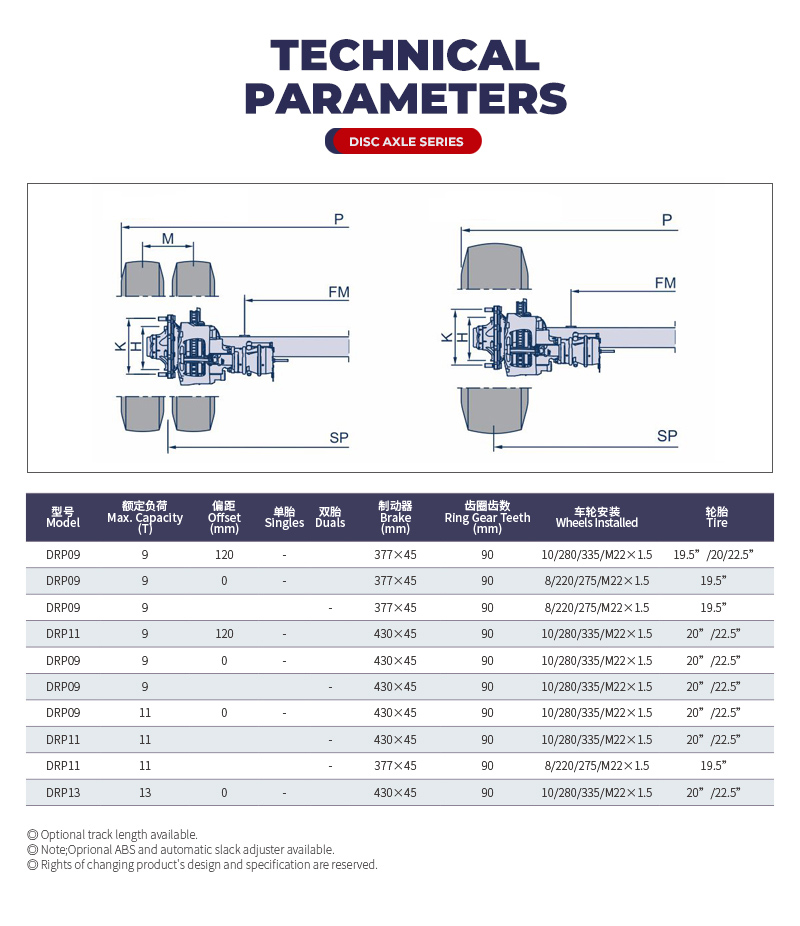

Axle load:9T

Brake:377*45

Ring Gear Teeth:90

Wheels Installed: 10/280/335/M22*1.5

Products Description

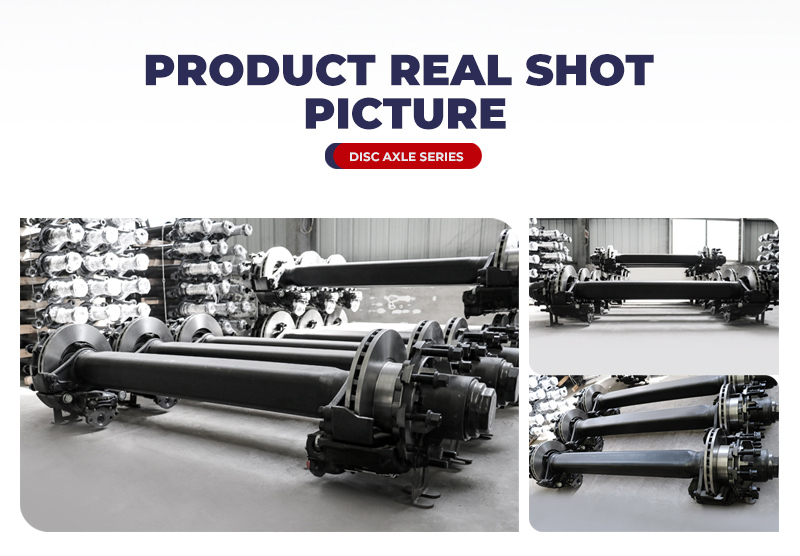

One-piece alloy Disc brake trailer axles , built with special technology, wear-resistant and crack-resistant, efficient heat dissipation.

High-strength bearings for trailers, effectively extending service life.

Partially reinforced square axle beam with large cross-section coefficient and strong torsion and bending resistance.

Overall heat treatment technology, improve the overall mechanical properties of the axle, good fatigue resistance and toughness.

Sensitive braking, stronger stability, safer braking with ABS and EBS system.

Strong heavy load capacity

-- the use of unique thickened shaft + low rolling resistance bearing, twin design, the bearing capacity greatly improved.

Good general performance

- suitable for all kinds of trailer scenes, can be used as different equipment chassis walking mechanism.

Flexible configuration

- according to the drawings of the axle processing, to meet the differentiated needs of customers.

High processing precision

-- automatic standard production line, higher operating precision, improve product safety.

Application Scenario

In GB7258-2017 after the implementation of the market products, Disc brake trailer axles this standard stipulates that the three axis of the fence car, dangerous goods transport vehicles and grid vehicles in January 1, 2020 after must be equipped with disc axle and air suspension, this is also for road traffic safety, disc axle compared with drum axle, in the braking system has a huge advantage. Disc brake is more sensitive, braking force is linear, braking force is large, combined with hydraulic retarder and ABS system to drive safety more than a layer of protection.

Package & Delivery