A good horse with a good saddle, a trailer axle is not as simple as it looks

As the saying goes: a good horse deserves a good saddle, and the same goes for semi-trailers. For the semi-trailer, the axle is a very critical part, related to the load bearing, braking and driving of the vehicle, what kind of axle to choose is crucial to the stability, safety and economy of the vehicle.

In this article, we will do a detailed analysis of the trailer rear axle, introduce the various components of the axle, and the key technologies and processes in the production process of the trailer axle.

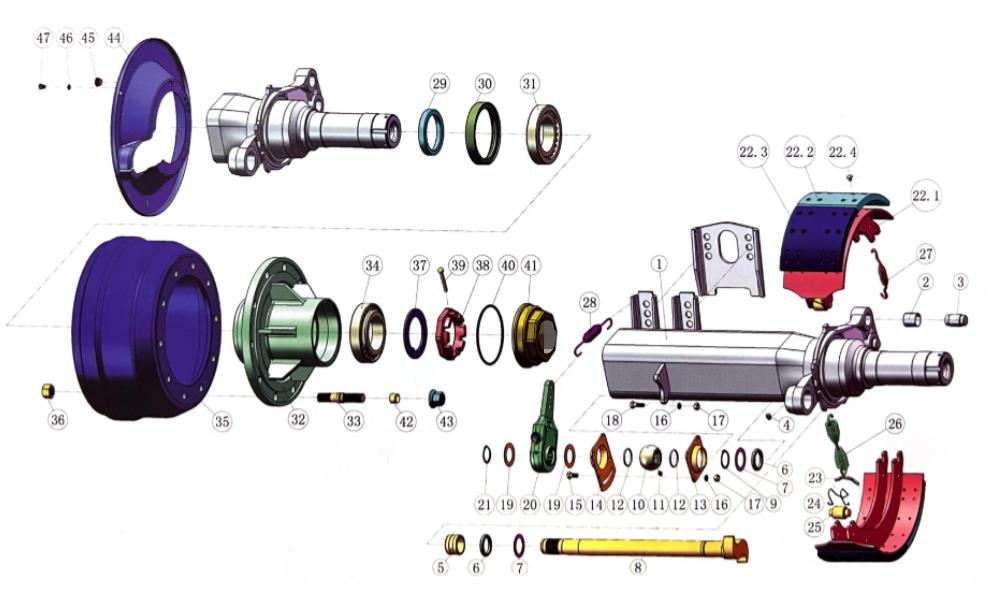

General drum trailer axle structure schematic

The above is a simple structure diagram of the ordinary drum axle, from which we can clearly see the main components of the axle and their positions. Generally speaking, the rear axle of the trailer is mainly composed of the shaft body, camshaft assembly, brake assembly, shaft end assembly and cotter pin, adjusting arm, various washers, nuts and bolts.

1. Total axial body

It mainly includes axle body, brake bottom plate, spherical bearing seat, air chamber seat, etc., which is located in the central position of the axle and connects the two sides of the wheel end, belonging to a semi-finished axle.

The axle body, that is, the bridge rod that the owners often say, connects the wheels through the wheel end assembly at both ends, and connects the frame through the suspension system in the middle. The top of the frame is the main position of the cargo loading. Therefore, the strength of the axle heavy load performance directly determines the bearing capacity of the semi-trailer, and is also an important performance parameter for the owner to choose the axle product.

2, camshaft assembly

It mainly includes camshaft, camshaft head washer, CAM shaft bushing, camshaft skeleton oil seal, camshaft washer, camshaft retaining ring, spherical bearing bolt and nut, spherical bearing, oil cup cover, etc.

3. Brake assembly

It mainly includes brake shoe roller, brake shoe return spring, brake shoe extension spring, brake shoe support, spring fixing pin, brake shoe, brake friction plate and so on.

For the drum axle, the brake shoe is the main friction couple, in addition to having the required strength and stiffness, but also as far as possible to have a high and stable friction coefficient, as well as appropriate wear resistance, heat resistance, heat dissipation and heat capacity.

4. Wheel end assembly

It mainly includes hub cap, hub cap washer, bearing, hub bolt and nut, hub, brake drum, hub oil seal, dust cap, grease and so on.

Wheel end assembly is the main part of the trailer axle that needs regular maintenance and maintenance, in general, every 50,000 kilometers of the trailer, it is necessary to do a maintenance of the hub bearings, to ensure that the bearings, hubs, etc., maintain good performance output, maintenance-free axle maintenance cycle can reach 30W or 50W kilometers.

Although the rear axle of the semi trailer is simple in appearance, the number of parts is relatively large and the composition is relatively complex, and the problem of any one of the parts, such as unqualified quality or non-standard installation, may have a direct impact on the overall performance of the axle, and even cause serious accidents such as broken axle, axle head fire, tire flying out, brake failure, and vehicle lying down.

In order to fully guarantee the performance and quality of the axle, what key technologies or processes do a qualified trailer axle factory need to have? Next, take the DARO trailer axle as an example to give you a brief introduction.

1, "one-piece" heat treatment molding

Heat treatment and forming process are generally inseparable. The raw material selected by DARO trailer axle is 20Mn2 high-strength alloy seamless steel pipe. Through "one-piece" heat treatment, the raw material is heated to a given temperature and maintained for a certain time, reducing the hardness and improving the plasticity of the raw material. Then, through the molding process, the shaft beam and shaft head are directly created from a complete steel pipe, and then cooled with the selected speed and method. To obtain the required microstructure and mechanical properties.

Different from the traditional "three-piece" shaft body, the shaft beam and shaft head of the "one-piece" heat-treated axle are naturally integrated, without additional manual welding, which can fully avoid welding deformation, ensure the accuracy and parameters of the shaft body, reduce the weight of the shaft body, enhance the connection strength of the shaft head and shaft beam, and solve the deformation and bending problems of the axle under high strength transportation.

2, shaft head strengthening and grinding

If the heat treatment is the axle "health", in order to obtain internal stable performance, the precision grinding is like the appearance modification, in order to obtain external processing accuracy.

We all know that if a tall building is to be built steadily and high, the foundation must be laid well. Shaft head grinding is like laying the foundation, whether it is boring, drilling, milling keyway and other processes, only the processing parameters, size, accuracy, etc. are mastered, the subsequent installation of bearings on the shaft head, wheel hub, brake drum can play a stable performance.

In addition to accuracy, the strength of the shaft head is also critical. DARO trailer axle specially added the shaft head intermediate frequency strengthening process, specially for the bearing connection part of the strengthening process, to further improve its use strength, to ensure that the performance output is more stable at high frequency speed, extend the service life of the trailer axle.

3, high standard assembly line

Assembly is the most cumbersome process on the axle production line, which involves dozens of types of parts, the number of hundreds, any one of which fails to meet the specified installation standards, will have an immeasurable impact on the performance of the axle.

In order to ensure the quality of the finished product, DARO trailer axle assembly selected brake drum, hub, bearings and other key components are supplied by domestic manufacturers and through multiple quality tests, the performance output is more stable. The assembly line has a high degree of automation, 100% online monitoring, all assembly parameters and parts can be traced, stable and reliable quality, and has the characteristics of long service life, long maintenance cycle and convenient maintenance.

At present, DARO trailer axle automatic assembly line is fully laid, the degree of intelligence is further improved, improve the assembly efficiency, but also for the assembly quality and accuracy escort.

4. Finished product quality test

Finished product quality testing is the last step in the production of trailer axles, and it is also a crucial step to verify the accuracy and reliability of the product. DARO trailer axle assembly after the completion of batch sampling test, only successfully passed the fatigue test bench, salt spray testing machine, shaft magnetic particle detection machine and other quality inspection processes, can enter the warehouse, waiting for the subsequent delivery.

Of course, the strength of a trailer axle factory in addition to the technical and technological level, R & D design capabilities, customized production capabilities, quality assurance capabilities and even excellent skilled workshop personnel are also indispensable. When the user inspects the axle factory, he can pay more attention to it.