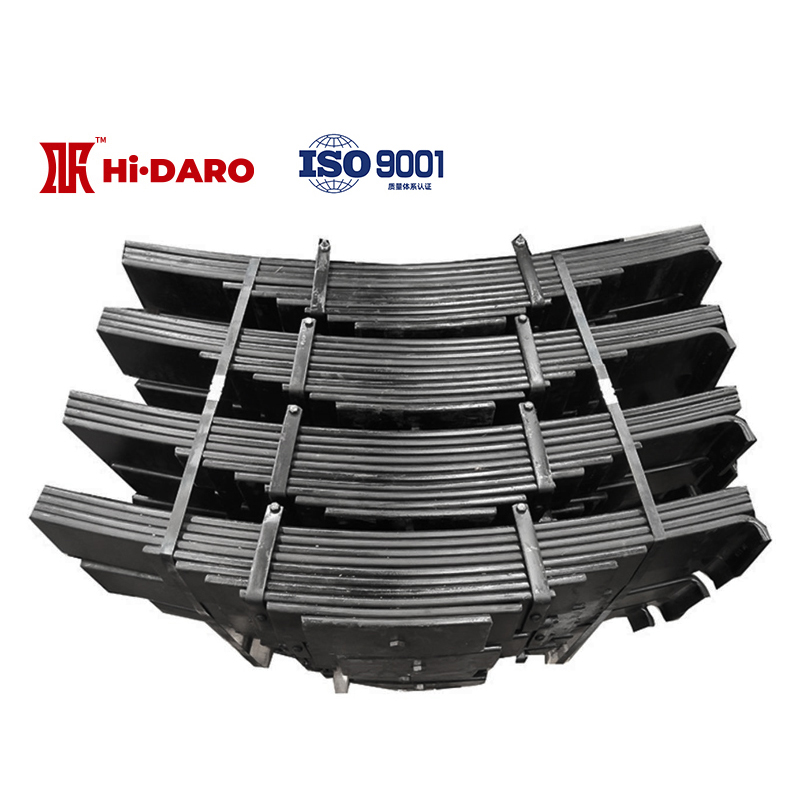

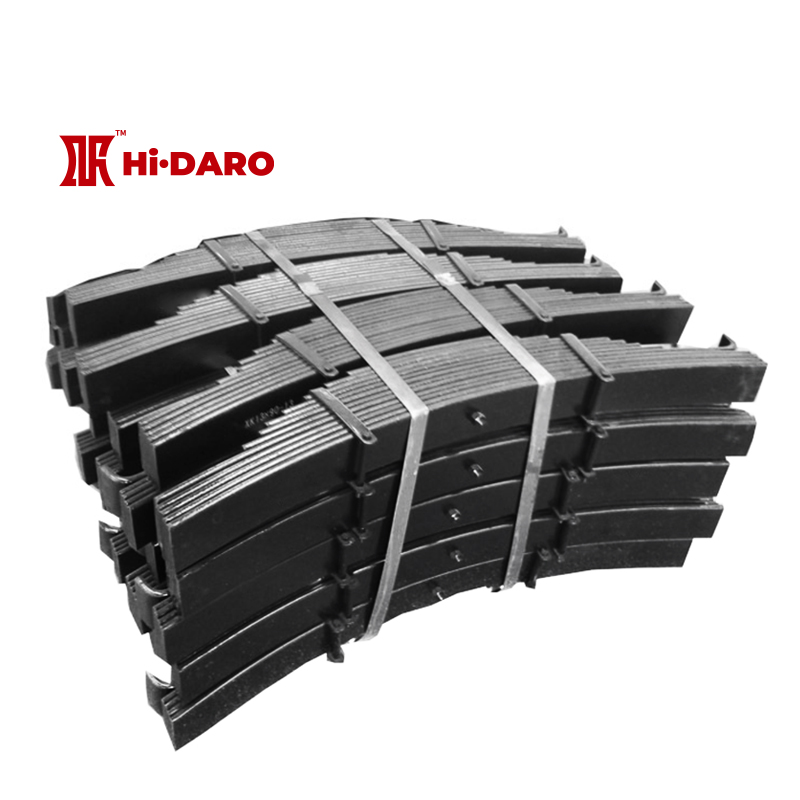

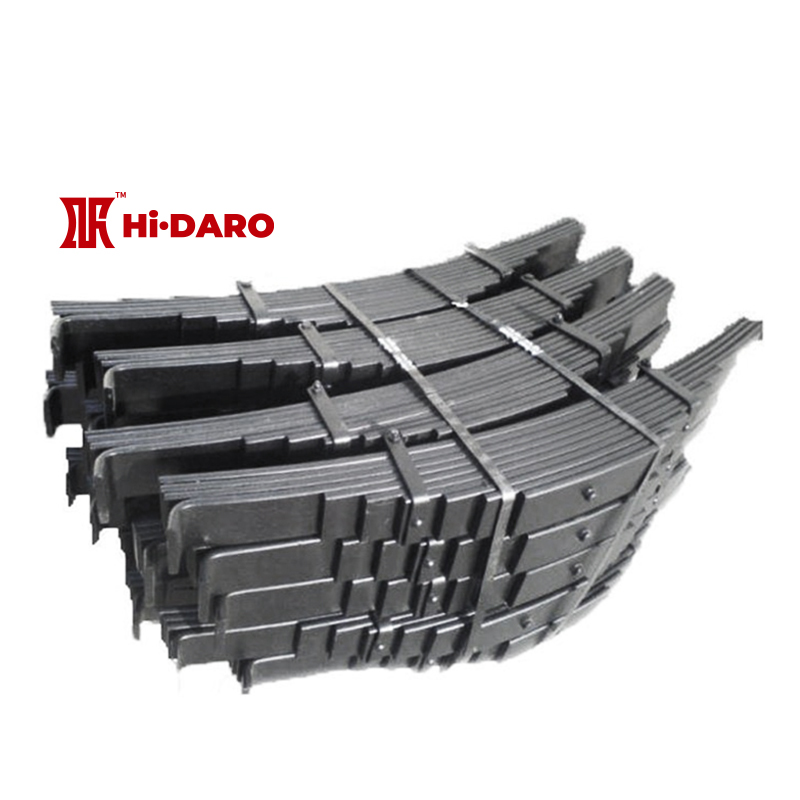

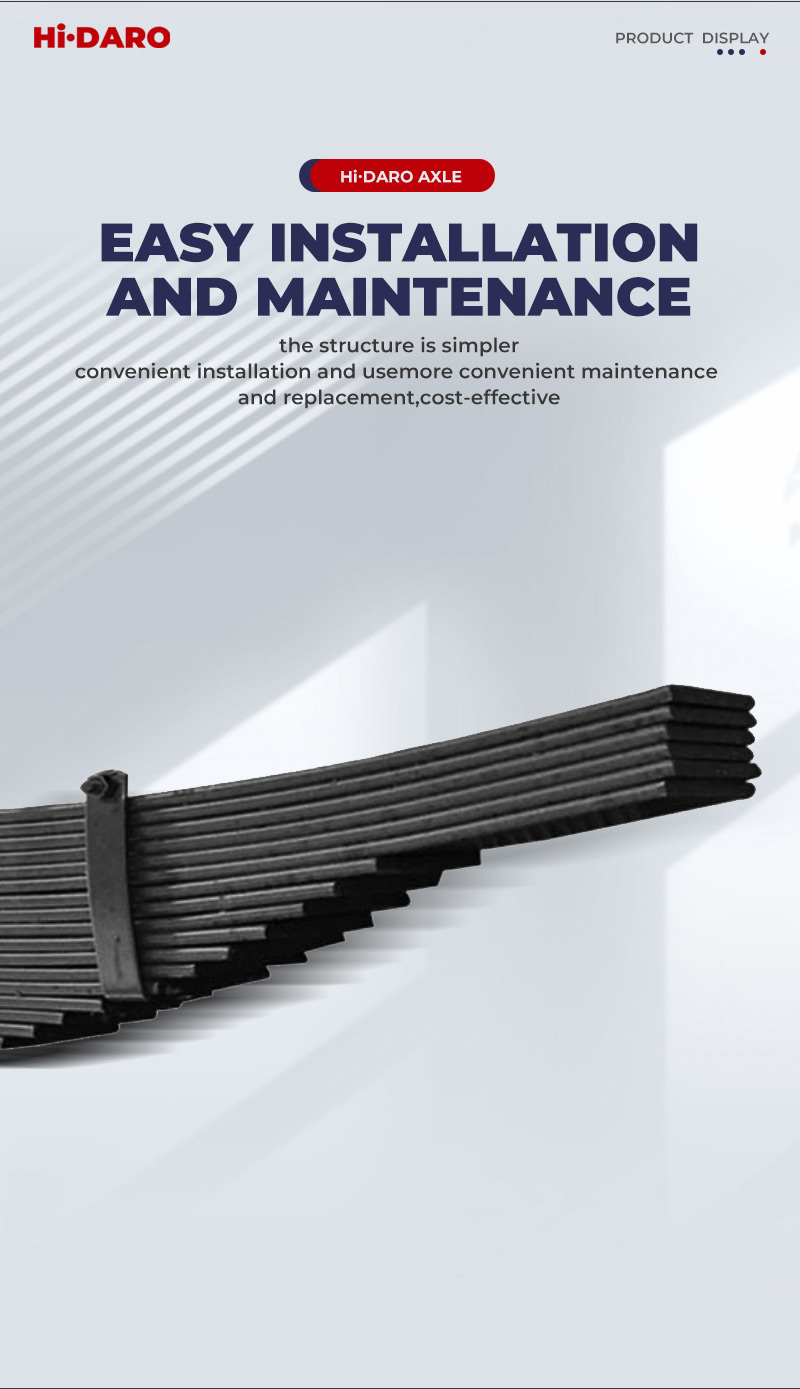

rear leaf spring

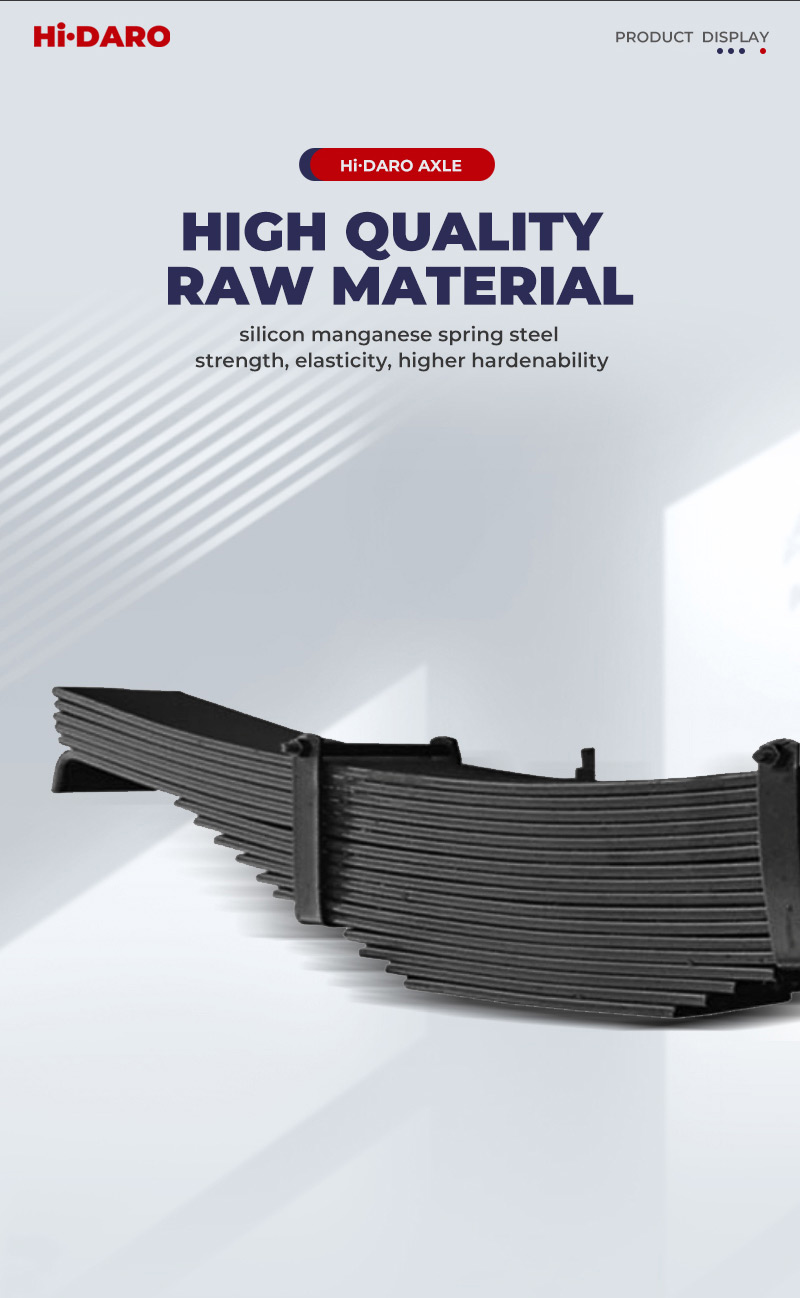

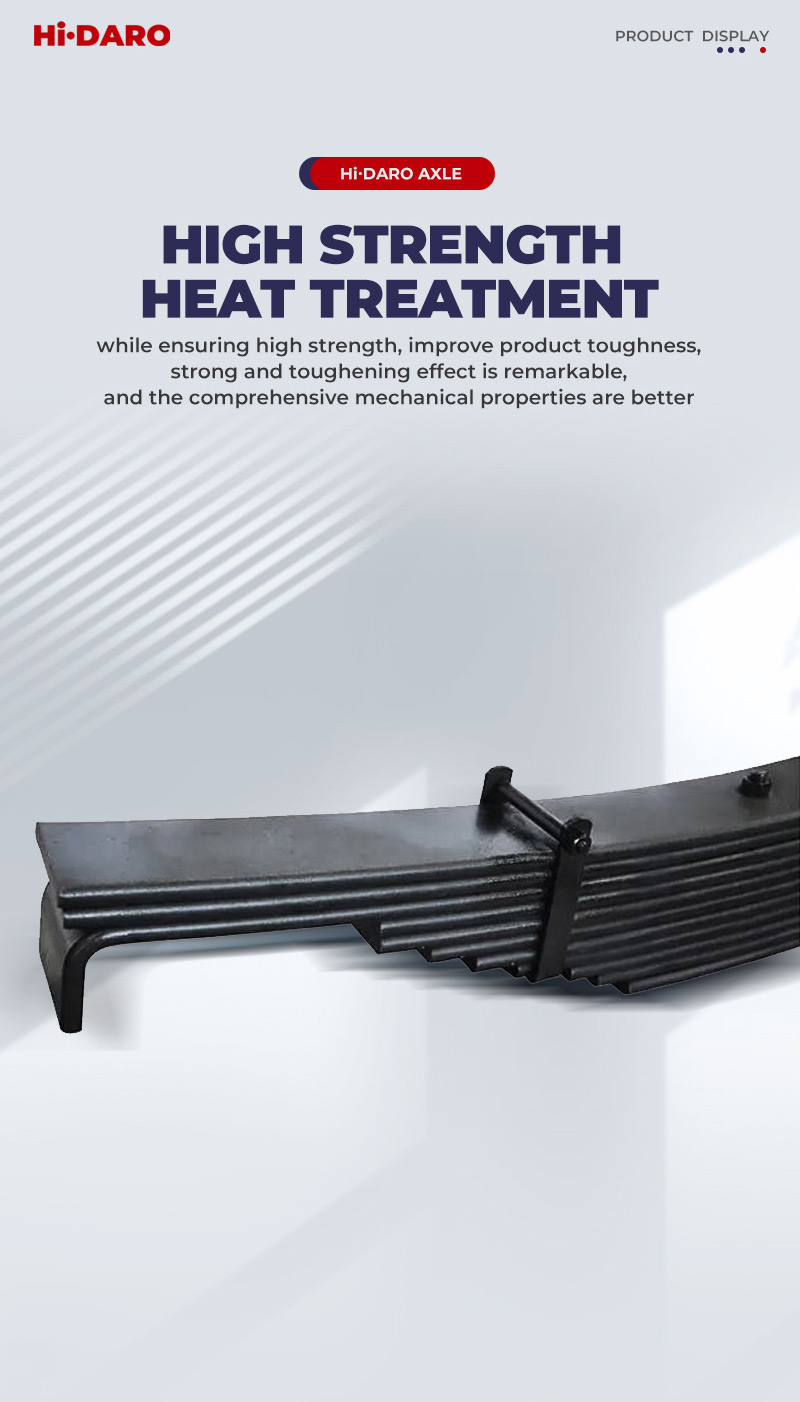

Spring steel is a widely used silicon manganese spring steel with slightly higher strength, elasticity, and hardenability than 55Si2Mn. In the 60Si2Mn spring steel industry, flat springs or coil springs with a wire diameter of less than 30mm can be manufactured to withstand large loads, heat resistant springs with a working temperature of less than 250 ℃ in non corrosive media, large important coil springs that can withstand alternating loads and work under high stress, and automotive shock absorption systems can also be manufactured.

Material: rear leaf spring

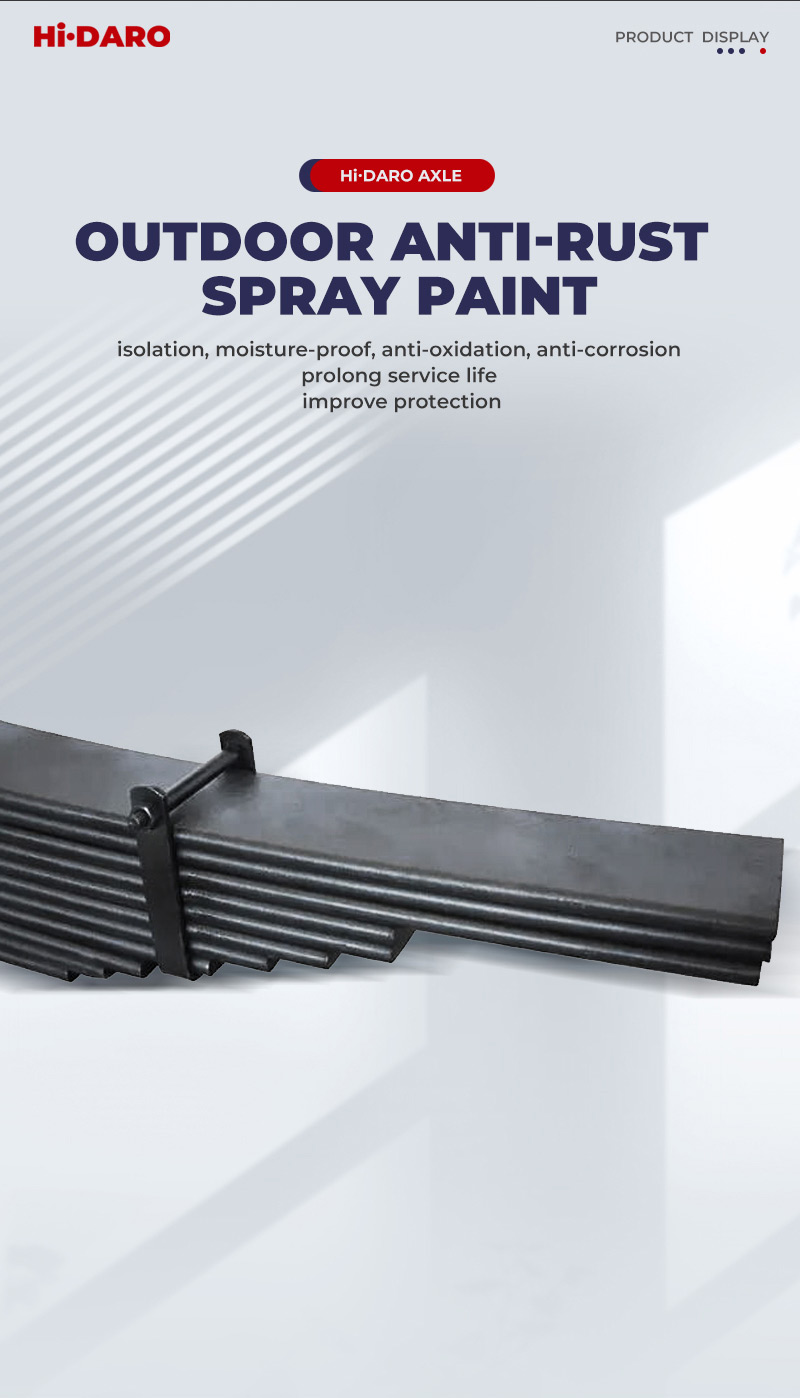

Surface treatment: shot blasting

Working form: stretching

Height: 5-45 (mm)

Brand: DARO

Products Description

65, 70, 85: Very high strength, hardness, and yield ratio can be obtained, but with low hardenability, poor heat resistance, and low ability to withstand dynamic and fatigue loads. It is widely used, but is mostly used for small springs with low operating temperatures or relatively important large springs.". For example, the spring 65Mn used in automobiles, tractors, railway vehicles, and general machinery has simple composition, better hardenability, comprehensive mechanical properties, decarburization, and other technological properties than carbon steel, but it is relatively sensitive to overheating, has temper brittleness, and is prone to cracking during quenching at a lower price, and requires a large amount of material. Manufacture various small cross-section flat springs, round springs, spring springs, etc., as well as valve springs, spring rings, shock absorbers, clutch springs, brake springs, etc.

30W4Cr2VA high strength heat resistant spring steel. Good hardenability. High temperature anti relaxation and thermal processing performance are also good. Heat-resistant springs with operating temperatures below 500~C, such as steam turbine main steam valve springs, steam seal spring pieces, boiler safety valve springs, 400t boiler disc valve springs, etc.

60Si2CrA 60Si2CrVA high-strength spring steel. High hardenability and good heat treatment performance. Due to its high strength, it is necessary to promptly handle and eliminate internal stress after winding the spring to manufacture important large springs with large loads. 60Si2CrA can be used for manufacturing steam turbine seal springs, adjustment springs, condenser support springs, high-pressure water pump disc springs, etc. 60Si2CrVA steel is also used to make extremely important springs, such as conventional weapon ammunition hook springs and crusher springs.

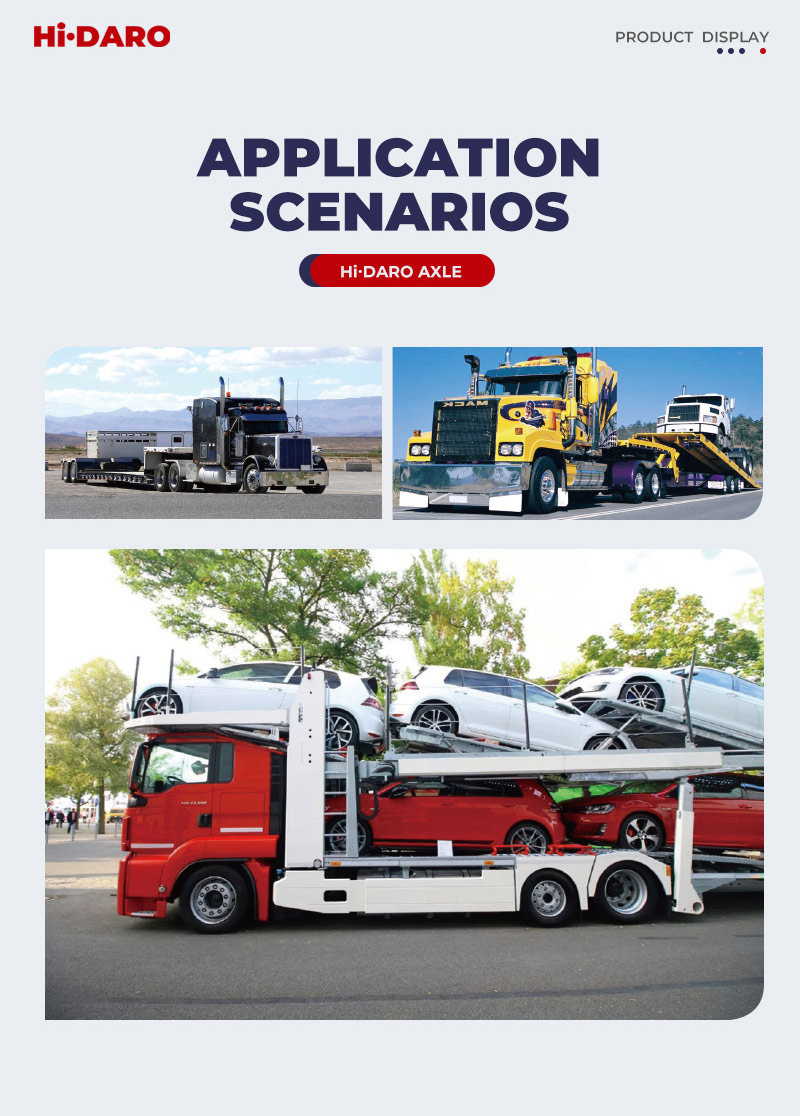

Application Scenario

Package & Delivery