Why don't many off-road vehicles use portal axles?

According to different division methods, automobile axles can be divided into many types, such as integral axles and disconnected axles according to structure, and steering axles, drive axles, steering drive axles and support axles according to functions. Among them, the drive axle can be subdivided into single-stage reduction axle (half axle axle) and double-stage reduction axle (wheel side axle, wheel reduction axle). The portal axle we are going to talk about today is strictly a variant of the wheel-side axle.

We all know that the diameter of the final reducer basin teeth of the wheel-side axle is small, the size of the axle package is smaller, the vehicle has a large ground clearance, and the trafficability is good, which is suitable for use in complex road conditions. However, if you encounter some extreme road conditions, ordinary wheel-side axles may not meet the requirements. At this time, portal axles are needed.

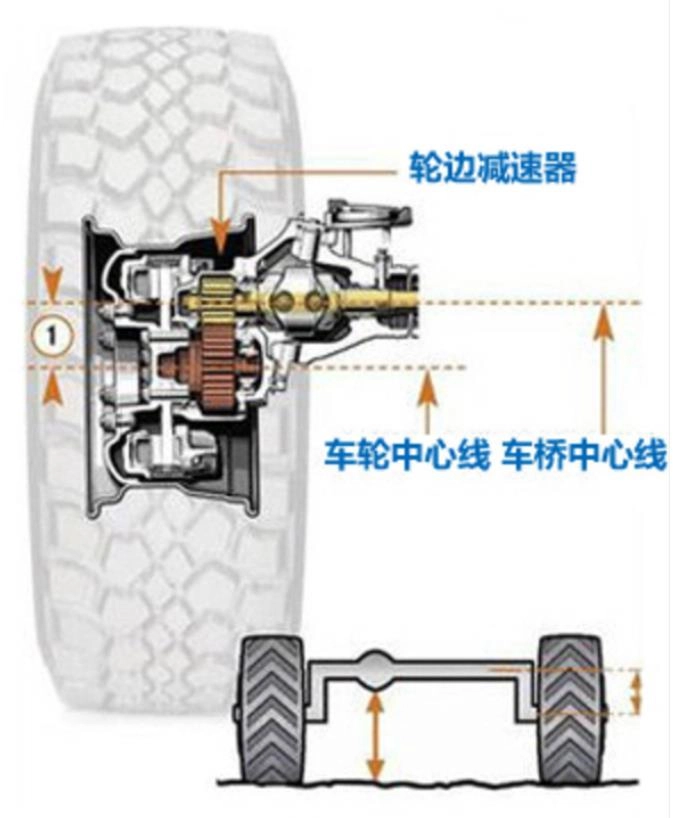

The design principle of the portal axle is simply that the axle originally installed at the center of the wheel moves upward to above the center of the wheel, and the rotational motion is transmitted downward to the wheel through gear transmission. As a result, the wheel size and shock absorber travel have not changed, but the ground clearance of the chassis, axle shafts, drive shafts and differentials has been increased.

Because the axle installed in this way looks like a door frame as a whole, it is named "portal axle".

As for the characteristics of portal axles, we briefly analyze them from two perspectives: advantages and disadvantages:

Advantage:

1. The ground clearance of the vehicle chassis is higher, and the vehicle passability is greatly improved, which is suitable for climbing mountains and ridges and passing through jungles.

2. The components of the transmission system, such as the gearbox and the drive shaft, tend to be lighter in order to lower the center of gravity of the vehicle.

Disadvantages:

1. The production cost, purchase cost and post-maintenance cost are high.

2. The design of the hub assembly is more complicated, which will easily increase the unsprung weight and affect the handling stability. It is not suitable for ordinary vehicles that often run on urban roads.

3. Stronger shaft control components are required, the more parts there are, the higher the failure rate.

Portal axles are specially made for extreme environments. They were first used on combat vehicles and later gradually applied to some off-road vehicles. But as mentioned above, the portal axle is to a certain extent at the expense of vehicle handling stability to obtain higher passability. It is suitable for extreme road conditions in the field and can be used on ordinary field road conditions or urban roads. Not quite right. This is why many off-road vehicles are not equipped with portal axles.

In addition, I don’t know if you have noticed that the city buses you usually take have two or three steps in the early years, but now some models have become the style that you can enter the compartment in one step. Some of the buses with particularly low chassis and one-step carriage also use portal axles, but they are used in reverse, changing from a high chassis to a low chassis, making it easier for passengers to get on and off, such as wheelchairs and baby carriages The difficulty of getting on and off the car is reduced, and with the air spring, the driving comfort has also been greatly improved.