Which operating conditions are suitable for the half shaft and the wheel shaft?

Trailer axle is one of the key components of vehicle chassis, which is directly related to the efficiency of vehicle operation. From the perspective of classification, axles can be divided into four categories: drive axles, steering axles, steering drive axles and support axles. Among them, the steering axle and the support axle (also called the trailer axle) do not have a drive shaft, which belongs to the driven axle; The drive axle and the steering drive axle are more complex and need to bear the power transmission of the vehicle.

The common drive axle is mainly composed of the main reducer, differential, half shaft, drive shaft housing and other components, and the specific functions can be divided into the following four points:

1. The engine torque from the universal transmission device is transmitted to the wheel through the main reducer, differential, half shaft and wheel hub, etc., so as to reduce the speed and increase the torque;

2, through the main reducer bevel gear pair to change the direction of torque transmission;

3, through the differential to achieve the differential effect of both sides of the wheels, to ensure that the inner and outer wheels to turn at different speeds;

4, through the axle housing and wheels, to achieve load and force transmission.

We often say that the single-stage reduction axle and two-stage reduction axle are typical drive axles, but there are many differences in the structure and performance of these two axles.

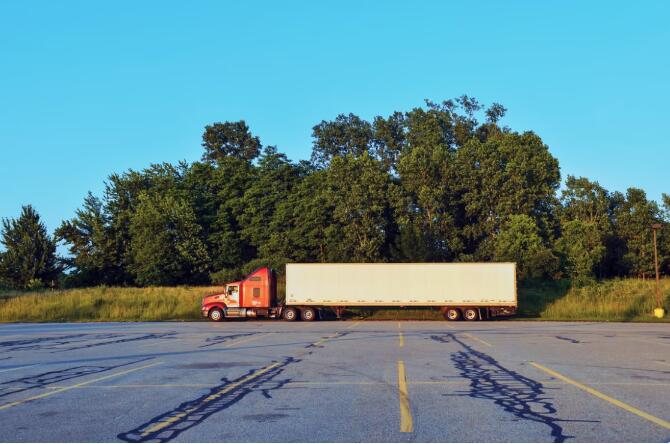

The axle has light weight and convenient maintenance, which is suitable for highway load transport

Single-stage reduction axle, commonly known as semi-axle, because of its large differential shell volume, many owners also call it "big belly axle".

From the structural point of view, the half shaft is mainly composed of an active bevel gear (commonly known as angular teeth) and a driven bevel gear (commonly known as basin teeth), which is simple in structure, relatively light in weight, low in failure rate, and more convenient in maintenance.

However, the torque amplification effect of the half shaft is not prominent, because the gear diameter of the main reducer is relatively large, the axle inclusion body is also large, which causes the vehicle clearance from the ground is small, affecting the vehicle's passability, especially in poor road conditions, the disadvantage of the half shaft is more obvious.

These characteristics lead to the semi-axle axle is more suitable for use in good working conditions, such as on-load transport, high-speed transport and other driving road conditions are relatively flat and to the on-load transport based vehicles, not only excellent lightweight performance, low fuel consumption, but also effectively prevent the shaft head due to long-term high-speed driving caused by high temperature phenomenon. The more common single-stage reduction axle models are 435, 440, 457, 459, 460, 469 and so on.

The two-stage reduction axle has strong power and good passability, suitable for complex road conditions.

Two-stage reduction axle, also known as the wheel axle or wheel reduction axle, compared with the half axle, adds a group of deceleration transmission of the wheel edge, and passes the torque of two stages of amplification to the wheel, the driving force is very strong. At the same time, the diameter of the basin teeth of the main reducer of the wheel axle is reduced, the volume of the shaft pack is obviously smaller, the vehicle clearance from the ground is large enough, and the passability is good.

However, the more complex structure not only affects the transmission efficiency, but also the technical requirements of assembly and maintenance are relatively high, and it costs more fuel to run. When the vehicle is driving at high speed, because the wheel reducer undertakes most of the task of variable speed and torque increase, the heat generated by the friction between the tire and the ground is easy to concentrate on the wheel end, resulting in poor heat dissipation conditions, which is not suitable for long time and long distance driving.

In contrast, the wheel axle is more suitable for low-speed and heavy-duty transportation under complex conditions such as site, unpaved road, and muddy road, and its powerful driving force and high passing performance can provide stronger escape ability and more durable.

To sum up, the semi-axle is suitable for on-load road logistics transport, and the transport condition with good road condition and small load; The wheel axle is more suitable for the construction vehicle with poor road condition, much climbing and heavy load. Although these two axles are the same as the drive axles, the owner should consider the actual use needs comprehensively when choosing.