Which method of brake cooling is more reliable?

How to cool the trailer's braking system is an old topic. When the trailer is carrying goods, the inertia is large, and a few brakes will appear the brake heat. If the brakes are used frequently for a long time, it is easy to lead to overheating of the brakes, affecting the braking performance, or causing a tire burst or brake spontaneous combustion, affecting driving safety.

Especially for those owners who often run mountain roads or long downhill road conditions, how to achieve efficient cooling of the brake system in the state of continuous braking is a more difficult problem.

As for the solution, the common ones are mainly water sprinkling devices, engine braking and hydraulic retarders, and there are new inventions of various "gods".

Today, DARO trailer axle will introduce in detail what are the advantages and disadvantages of these brake cooling methods.

Let's start with the common ones:

1. Shower to cool down.

The water cooling device belongs to a folk invention, which is a talisman for the owners who often run in the mountainous area of Yunguichuan.

The water cooling price is cheap, the installation is more convenient, and the cooling effect is more obvious, so it has been rapidly popularized and promoted in the industry.

However, with the continuous development of vehicle technology, water cooling has gradually begun to "fall out of favor." The reasons are as follows: (1) the weight of the sprinkler is too large, often tons or even several tons, the impact on the load of goods is relatively large, the transportation cost increases, and the use of the long time is also easy to lead to the deformation of the frame.

(2) It is easy to lead to ice on the road, especially in the north, during the process of water cooling, water falls on the road, prone to ice phenomenon, affecting driving safety, if ice appears in the downhill section, the risk is greater, so like Shanxi, Shaanxi and other mountain roads have banned water cooling in winter.

(3) The disc brake gradually began to be popular on the trailer, but the water cooling device is not suitable for the disc brake, resulting in owners having to choose other auxiliary devices.

2, hydraulic retarder.

Compared with water cooling, liquid slow is a safer device, not only with constant speed control function, smooth braking without impact, and 90% of the braking is carried out by non-wear state, which can effectively avoid braking overheating.

In addition, the liquid slow volume is also small, the weight is lighter, and the service life of friction pieces, tires and other parts can be extended, the frequency of replacement can be reduced, and the cost of comprehensive vehicles can be saved.

In addition to playing a role in mountain road transportation, it can play the function of predictive braking and deceleration in road conditions such as toll stations, traffic lights, and traffic jams, and the application field is wider.

However, the price of liquid is too high, tens of thousands or even tens of thousands of yuan, which is a large amount for the owners, so the popularity is slightly worse.

3. Engine auxiliary braking.

Engine braking is the simplest form of braking. Release the clutch and throttle, and put the transmission in forward gear to enter engine braking mode.

However, engine braking has certain requirements for the operation and technology of the owner, and if the application is not skilled, it will also affect the auxiliary braking effect.

And then there are the "new inventions" :

1, circular disc brake.

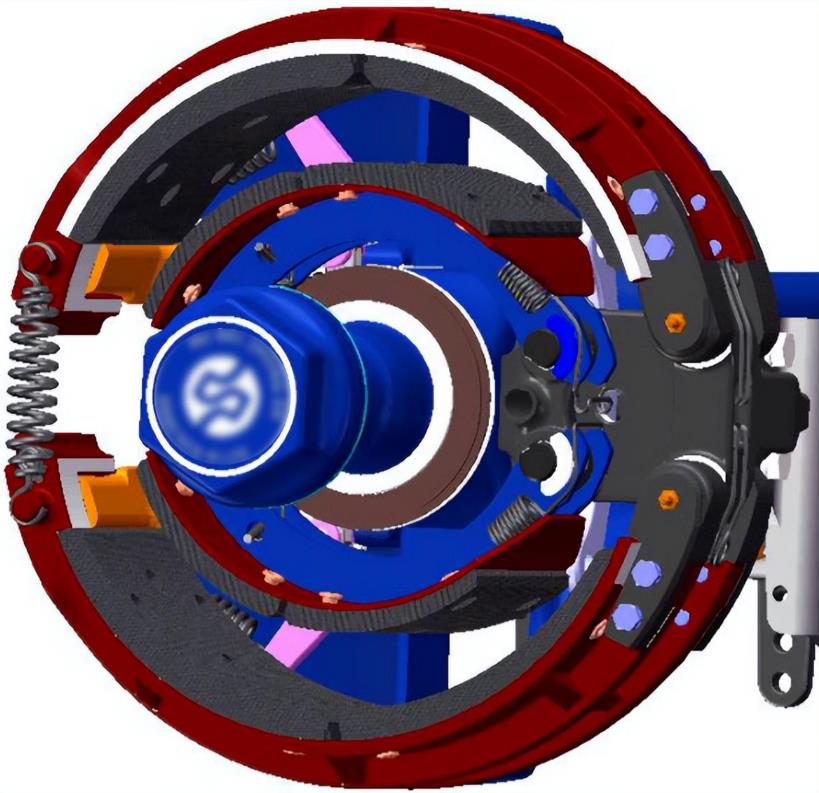

Many owners may not have heard of it, you can take a look at the diagram below:

In terms of appearance, this brake is more like a combination of drum brake and disc brake. The brake drum is used to brake, but part of the brake shoe is exposed to the air.

This brake has brake shoes on both the inside and outside of the "brake drum", so that the brake is pressed and the inside is stretched out, while the outside is also held in.

According to the design principle, the brake has large braking force, good heat dissipation performance, and the air guide is added in the middle. As the wheel speed increases, the air guide will blow inside the brake to help the brake heat dissipation.

However, these advantages are still only at the theoretical level, so far have not seen the large-scale application of this brake in the market. In addition, although this brake is called "circumferential disc", it can not be identified as "disc" in regulations.

2, heat dissipating rib cast aluminum steel ring.

Regarding the advantages of aluminum alloy, owners should understand more, not only lighter than the steel ring, but also better heat conduction performance. Coupled with the design of heat ribs and vents, it can play a forced ventilation effect, and the effect is good in theory.

However, the practical application of this design on the trailer is very few, one is the high price, and when facing a continuous long downhill, the heat dissipation effect may not be as good as imagined.

3. Water circulation axle.

It sounds unclear and severe, but it can actually be seen as an upgrade of the cooling water.

Add water storage tank, radiator and pipe on the trailer axle, driven by electric water pump, the pipe inside the shaft tube into both ends of the wheel hub, and then through the water separator into the brake drum sandwich for cooling, water temperature rises through the water separator back to the radiator for water cooling, and finally back to the water tank.

According to the design principle, such a device can achieve water circulation, avoid dripping onto the road.

However, for its heat dissipation effect, owners do not buy it. One is whether the water temperature will slowly evaporate after rising, without adding water is impossible; Another is the continuous long downhill will not boil; Then there will be no residue with the flow of water clogging the spray pipe. Therefore, the news of this design is basically unheard of in the market at present.

Combining the above several ways, it can be seen that although the price is indeed not beautiful, the liquid slow + disk brake will become the main force of the future market.

DARO disc trailer axle is currently a relatively high cost performance one, the use of domestic advanced "one-piece" heat treatment molding technology, with medium frequency quenching treatment, improve the bending, torsion and deformation resistance, while taking into account lightweight design, compared with traditional products reduced by about 15%, can fully help the owner of energy saving, improve the comprehensive operating income.