Which is better for electromagnetic suspension or air suspension?

Air suspension believe that many owners are not strange, this kind of suspension was born in the middle of the 19th century, is still widely used in all kinds of trucks, passenger cars, cars and railway vehicles.

According to relevant data, almost all the advanced buses in foreign countries have applied air suspension, the proportion of heavy trucks to air suspension has reached more than 80%, and the application rate of light vehicles to air suspension is also rising. In some special vehicles with high requirements for shock resistance, air suspension is almost the only choice.

In many luxury cars, the role of air suspension has almost reached the extreme. For example, the on-board computer system can control the camera to scan the road conditions in front of it, and then adjust the air suspension in advance according to the feedback information, so that the owners can get a better driving experience. As a result, many owners see air suspension as a must-have accessory for high-end cars.

However, the industry between the "inner volume" everywhere, the electromagnetic suspension was born. It is said that since the 1990s, the major car companies have invested in the electromagnetic suspension research and development, but due to the lack of technology and funds, the success is very few, which is more heavy electromagnetic suspension in the market scarcity, owners once believed that the electromagnetic suspension must be more advanced than air suspension.

In the previous article, we have introduced the air suspension in detail many times, here is not to repeat, today we briefly introduce the electromagnetic suspension.

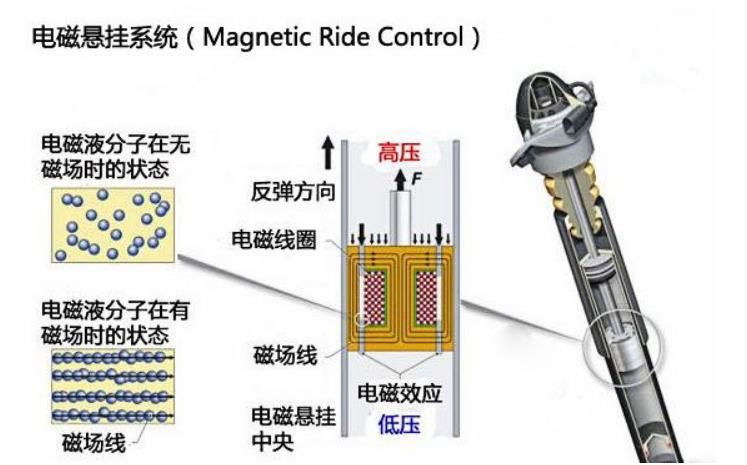

Electromagnetic suspension, also known as magnetorheological fluid shock absorber suspension, is an independent suspension made of special materials. The structure is mainly composed of vehicle-mounted control system, wheel displacement sensor, electromagnetic hydraulic rod and straight cylinder shock absorber.

The working principle of electromagnetic suspension

Electromagnetic suspension of the shock absorber internal use of electromagnetic liquid, composed of synthetic hydrocarbons and 3-10 micron size magnetic particles, control unit pulse signal, the coil will generate voltage to form a magnetic field, through the magnetic field to change the direction of particle arrangement, forming a chain, cluster structure, with a certain shear yield stress resistance. With the increase of magnetic field intensity, the magnetorheological fluid will become solid-like when the limit is reached, and the suspension damping reaches its peak.

Electromagnetic suspension features

1. Fast reaction speed

Because the damping change of electromagnetic suspension is completed through electromagnetic field, its damping switching speed is very fast, can make a response within 1 millisecond, almost equivalent to real-time change, can be called the fastest action, damping control of the most advanced suspension system.

2, stable body effect is good

Even on rough roads, the electromagnetic suspension increases tire contact with the road, reduces tire rebound, controls the vehicle's weight shift and tilt forward and back, and provides good control over body sway during tight turns or dodging.

3. Strong environmental adaptability

The electromagnetic suspension structure is simple, less power consumption, can be directly through the general battery power supply, control the stress range is large, is not sensitive to impurities, can work in -50℃-140℃ environment.

4. Low noise

Compared with the traditional suspension system, the electromagnetic suspension has fewer moving parts, and almost no collision between the parts during the working period, low noise and high ride comfort.

5. The cost is too high

Due to technical problems, the production cost of electromagnetic suspension, especially the maintenance cost, is much higher than the traditional suspension, not particularly cost-effective.

Application of electromagnetic suspension

Due to the excellent response speed of electromagnetic suspension, it is generally used on vehicles with heavy driving control, such as some high-end sports models.

So the question is: is the electromagnetic suspension superior to the air suspension?

In fact, from the above introduction, we can see that the electromagnetic suspension is more focused on the response speed, air suspension is more focused on riding comfort, it can be said that the two in their fields are the top king, to put together to say which is more advanced, there is no definite answer, it depends on the owner of which is more focused on the function.

Of course, the two are not incompatible, can also be used together, so that it can have super fast response speed, and can have a comfortable ride experience, but the cost of nature will be much higher, generally this kind of collocation appears in the top luxury car.

For freight vehicles, it is also mentioned above that the proportion of air suspension installed in foreign heavy trucks has reached more than 80%, which also shows from the side that electromagnetic suspension is not suitable for freight vehicles at present, and air suspension can basically meet the transportation needs of high-end goods.

Air suspension can also be divided into American and German two types, wherein the American air suspension guide arm weight is lighter, and the contact area with the axle is larger, the lateral support performance of the vehicle will be better; German type air suspension uses one or more plate spring structure as the guide arm, which has stronger bearing capacity, relatively longer air bag travel, better shock absorption performance, and stronger adaptability to road conditions. DARO Group's air suspension is specially designed for freight vehicles, the classic German design, strong toughness, good sealing, high bearing strength, long service life, with DARO disc trailer axle, can effectively reduce the loss of cargo, improve the efficiency of operation.