What part of the car is the axle?

Axle is one of the core components of semi-trailer, which is directly related to the strength of vehicle bearing capacity. Especially for the semi-trailer, as one of the main models of the domestic logistics transportation industry, its cargo carrying capacity must be fully up to standard, otherwise, to the small, affect the owner's operating income, to the large, affect the vehicle driving safety. Just imagine, if the vehicle is fully loaded at high speed and the axle breaks due to insufficient bearing capacity, the consequences will be unimaginable.

About the position of the axle, I believe that many owners can distinguish, is connected to the two ends of the vehicle wheel that shaft. The owner asked: Is the axle the same thing as the axle assembly? Not really. Although in peacetime many owners like to use the axle to call the axle assembly, but the two are different parts.

The axle is an optical shaft, and the axle assembly is based on the axle, which is welded with brake bottom plate, spherical bearing seat, air chamber seat, etc., to form the axle body. Then, on the basis of the axle body, the camshaft assembly, brake assembly, wheel end assembly, cotter pin, adjusting arm, ABS sensor, ABS positioning clip and other parts are installed to form the axle assembly.

The trailer axle, both ends of the wheel end assembly connected to the wheel, the middle through the suspension system connected to the frame, the frame above is the main position of the loading of goods, therefore, the strength of the axle heavy load performance, directly determines the size of the semi-trailer bearing capacity, is also an important performance parameter for the owner to choose the axle products. So, what kind of axle bearing capacity is stronger?

According to the different appearance style and manufacturing process, axles can be divided into American axles and German axles, the main difference between the two is the shaft head part.

From the appearance, the head of the American axle is thicker, maintaining the basic shape of the shaft tube and the shape is more regular;

German axle head is thinner, the end of the shaft processing is irregular, more inclined plane.

This leads to the American axle head position is thicker, the strength of the part connected with the bearing is higher, and the load that can bear is relatively larger.

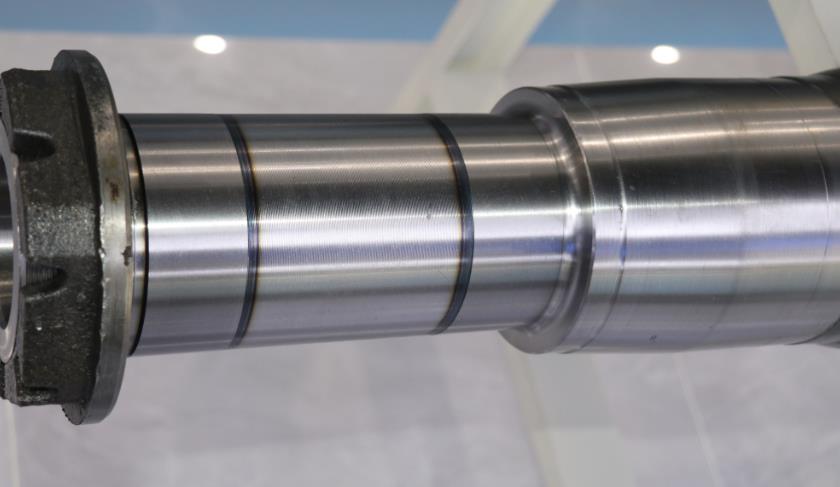

From the point of view of processing technology, the American axle is an integral shaft body building process, to put it more commonly, that is, the two ends of the shaft head and the middle of the shaft tube is one, are directly polished from a steel pipe;

The shaft heads at both ends of the traditional German axle are welded to the shaft body. The shaft body is the shaft body during production, and the shaft head is the shaft head. After production, they are welded together.

From this point of view, the American axle has no follow-up welding treatment, and the original unipiece axle has stronger anti-weight ability.

Throughout the current domestic axle market, the typical representative of American axle is Guangdong Fuhua. In 2005, Guangdong Fuhua introduced the integrated axle production technology from the United States and developed the first batch of integrated axle tubes in China. As the earliest American axle enterprise in China, its market share reached about 70%, the strength is very strong. However, the drawback is that the price is too high. As a first-line axle brand, Guangdong Fuhua's product line tends to be high-end, so its price naturally rises. Coupled with the premium of the brand, the products of the same specifications can even be about 30% higher than other brands.

So, there is no integrated axle production technology is more mature, the price is relatively popular other brands?

Yes, that's Shandong DARO. DARO is an early trailer axle enterprise in the north. It entered the production and manufacturing industry of trailer axle as early as 2001. In 2006, in order to improve the production efficiency and technology of axles, DARO R&D staff successfully developed an all-in-one axles production line after nearly two years of research and development and testing, becoming the first enterprise in Shandong Liangshan commercial Vehicle production base to mass-produce all-in-one axles. All the axles produced by DARO are made of high-strength alloy seamless steel tubes as raw materials. Fifteen production processes, including hot rolling at 1300℃, intermediate frequency quenching at 865℃, heat preservation and tempering at 480℃, multi-point online straightening and CNC precision grinding, are set up to fully ensure the strength, toughness, extensibility and durability of the axles. So far, it has gone through years of market baptism. The process and technology stand the test.