What is "half axis"? What's the difference with a common axle?

The half shaft is also called the drive shaft, is one of the important components on the drive axle, the main role is to connect the differential and the drive wheel, transmit torque between the reducer and the drive wheel, so that the drive wheel drives the vehicle. Because of the need to transmit torque, the half-shaft is mainly solid, but because the hollow shaft rotation imbalance control is easier, so many cars now also use hollow half-shaft.

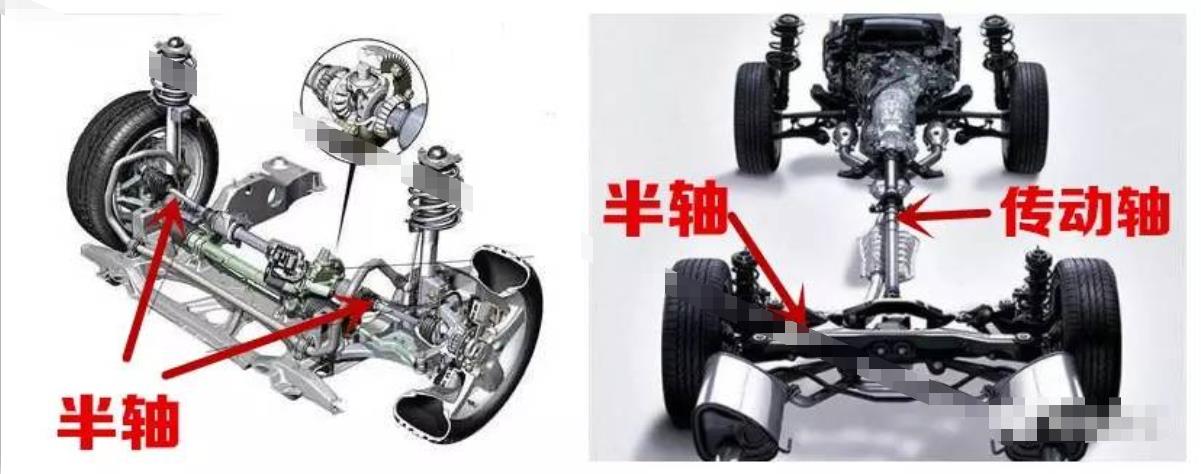

It is worth noting that the half shaft and the drive shaft are two completely different components. The half shaft is connected to the differential and the drive wheel, which are generally installed at the wheel end; The drive shaft connects the engine, driveline and differential, and is mounted in the center of the vehicle chassis structure. It can be distinguished by the following figure:

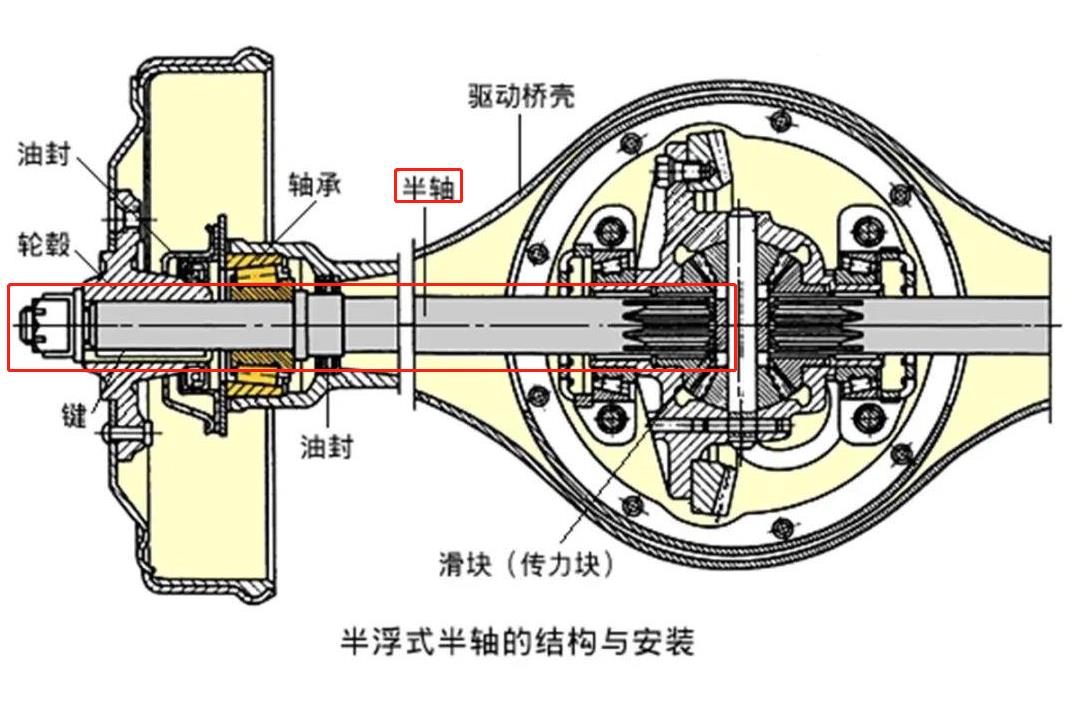

Why is the half-axis called "half-axis"? In fact, the name is still very image, because most of the half-axis is a half-type structure:

On the disconnecting drive axle, the main reducer housing is fixed on the frame, and the half axle and drive wheel on both sides can realize relative movement with the body; In the non-breaking drive axle, the half shaft is rigidly connected with the main reducer axle housing to form an integral beam, and the half shaft and the drive wheel on both sides are correlated with the swing.

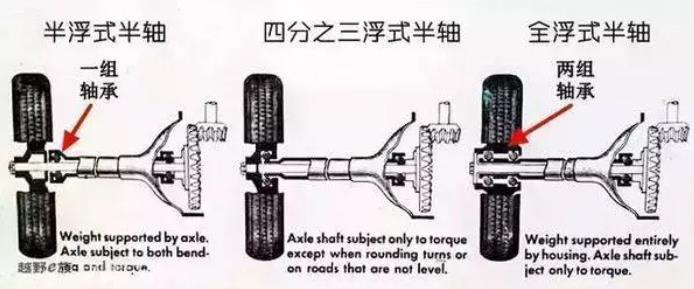

The common half-shaft can be divided into three types: full floating, 3/4 floating, and semi-floating.

The "float" here refers to a state in which the half shaft does not bear the bending load and only bears the torque load, and the full float, 3/4 float, and half float refer to different degrees of this state.

1. Full floating axle

When working, it only bears torque, and the two ends do not bear any force and bending moment. Generally speaking, it only bears the torque from the engine, and the load torque of the vehicle is all borne by the axle.

The outer flange of the fully floating half shaft is bolted to the hub, which in turn is mounted on the half shaft sleeve by two bearings that are further apart. Because of its reliable work, it is widely used in commercial vehicles.

2, 3/4 floating axle

In addition to bear all the torque, but also to bear a part of the bending moment, its most prominent structural feature is that the outer end of the shaft is only designed a bearing, bearing support hub. In addition to the torque, the semi-shaft also bears the bending moment caused by the vertical force, driving force and lateral force between the wheel and the road surface.

Due to the poor support stiffness of a bearing, the 3/4 floating axle is less used in automobiles, and is generally only used in passenger cars and vehicles with smaller total mass.

3. Semi-floating axle

The supporting bearing of the semi-floating shaft is located in the inner hole of the outer end of the half-shaft sleeve tube, and the wheel is mounted on the half-shaft. In addition to transferring torque, the outer end also bears all the force and torque caused by the reaction of the road to the wheel.

The semi-floating axle is used in passenger cars and some commercial vehicles because of its simple structure, small mass and large load.