What is the difference between gas brake and oil brake?

Whether the braking performance is good or not is an important parameter when consumers choose vehicles. In the vehicle braking method, the air brake and the oil brake are two kinds of relatively high utilization rate, today we will talk about the difference between the air brake and the oil brake, and what models are applicable to trailer axle.

1. Structure

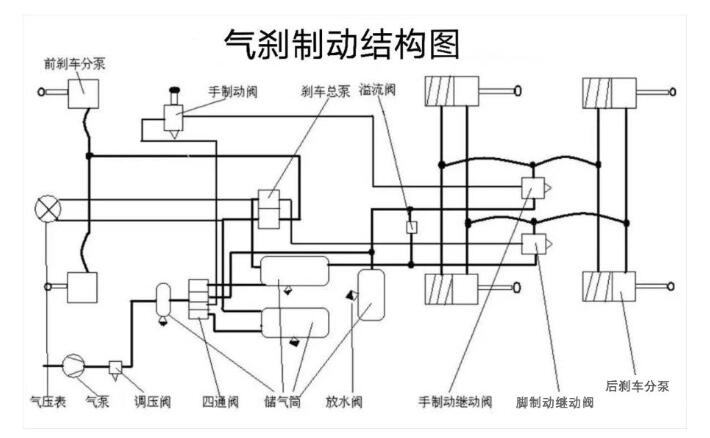

The air brake is generally composed of air compressor, brake valve, brake chamber, gas reservoir, pressure gauge, air pump, pressure spring, safety valve, brake pipeline and other components.

The structure of the air brake is relatively complex, and the required installation space is also relatively large, which is suitable for medium and large vehicles.

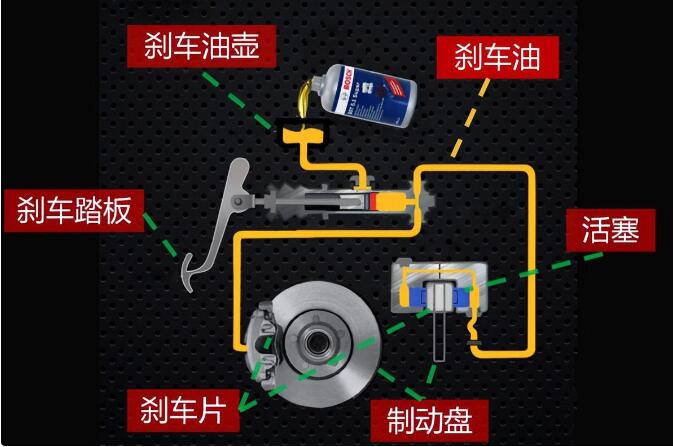

In contrast, the structure of the oil brake is simpler, generally composed of the brake master pump, sub-pump, oil cup and connecting pipelines, etc., and braking is performed by the engine oil pump power. This also makes its installation space small, suitable for small vehicles.

In terms of braking media, the two are also different, the air brake mainly relies on air, after pressure to promote the brake pad work; The oil brake is based on the special brake oil as the medium, and the brake pads are pushed through the oil.

2. Principle

Air Brake:

It mainly relies on pneumatic drive to achieve power braking.

When the vehicle stops, the push rod of the brake chamber controls the brake in the braking state under the action of the spring force;

After the vehicle starts, the air pump runs, and when the brake chamber push rod overcomes the spring force under the action of air pressure, the brake brake state is released, and the car can run;

When it is necessary to brake, the brake pedal controls the brake valve, so that the pressure in the brake chamber is released, and the push rod brakes under the action of the spring force trailer axle.

Oil brake:

When the owner steps on the brake, the piston and seal bowl in the brake master pump will be pushed by the brake pedal, the push rod acts, the brake oil is transmitted to the piston of the brake pump through the oil pipe, and then the friction sheet and the brake drum produce friction and brake effect.

3. Features

Air Brake:

The reaction speed is fast, the braking force is strong, and the size of the braking force output is only related to the air pressure in the air reservoir and the opening degree of the valve, and has nothing to do with the strength of the downstep. It is not easy to slide in uphill and downhill road conditions, full speed can be stopped, and sudden braking is not easy to roll over.

The structure is relatively complex, the installation space is large, the brake wear is obvious, and the later maintenance is relatively complicated; Frequent stepping on the brake pedal when going downhill can also lead to insufficient air pressure and brake failure, and some old cars need to idle for a period of time after parking.

Oil brake:

Simple structure, small size, relatively small requirements for installation space, brake power output is relatively soft, not easy to lock, high riding comfort, fewer components, maintenance is more convenient.

The reaction speed is slightly slow, the braking force is weak, and the oil circuit needs regular maintenance.

4. Applicable models

The air brake is mostly used in medium and heavy duty trucks and heavy duty buses, and in recent years, the application of small light trucks is also more and more widely used with the air brake;

The oil brake is mostly installed on small tonnage models, such as passenger cars or small micro cards.

Therefore, if the car owner's model is a medium and heavy truck, the general choice of air brake braking;

If the owner uses a micro card or light truck, it is necessary to combine the daily operating conditions, if the carrying capacity is not large, the transportation speed is not fast, and the road condition is not complicated, the oil brake is generally enough; If the carrying capacity is large, often run high speed or walk complex road conditions, it is recommended to choose the air brake brake.

5, maintenance

Check the brake pad thickness and brake disc/brake drum wear degree regularly, when the brake pad thickness is found to be close to or less than the specified thickness, or the brake disc or brake drum surface dents, should be replaced immediately.

For vehicles with oil brake, check the liquid level of trailer axle the brake oil before getting out. If the oil level is found to drop, check whether there is leakage of the brake oil circuit immediately. Because the brake oil absorbs moisture in the air, it is easy to fail for a long time, and the brake oil should be replaced regularly according to the regulations, and it is best to replace it once a year.

Air brake vehicles should pay attention to often discharge the water in the system and regularly replace the dryer, the water in the air path system is easy to corrode the pipeline and affect the braking effect, and even lead to the brake system failure in serious cases. In addition, it is necessary to regularly check the working condition of the air pump and the wear of the air pump belt, and replace the problem in time if found.