What is the difference between low flat trailer axle and ordinary axle?

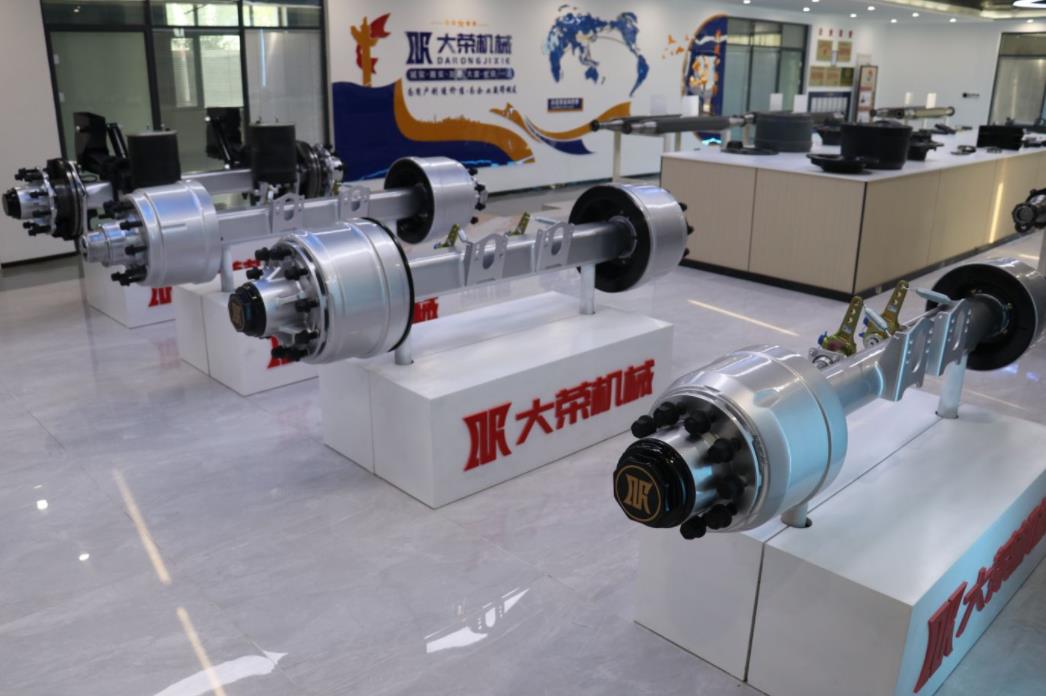

As a typical support axle, the trailer axle plays an important role in the fields of load bearing, braking, driving and even auxiliary shock absorption. In general, the trailer rear axle can be divided into two categories: disc type and drum type, and the subdivision can cover low flat trailer axles, three-line six-axles, eccentric trailer axles, special trailer axles, and so on. Today, we focus on low flatbed trailer axles.

1. What does a low flat trailer axle look like?

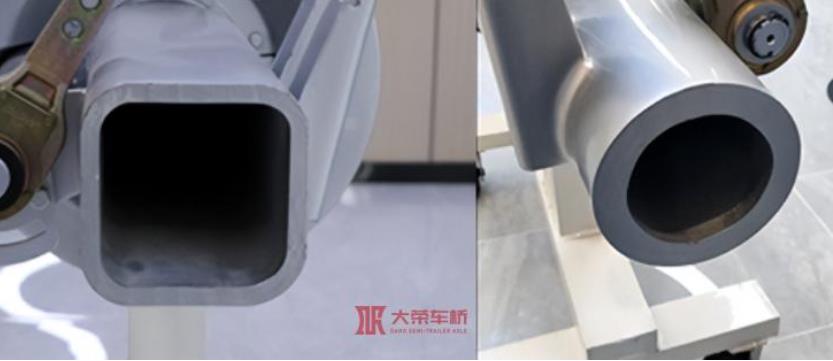

From the appearance point of view, low flat axles and ordinary trailer axles are relatively easy to distinguish.

Under normal circumstances, the wheel end part of the axle of the low flat trailer, such as the brake drum and the wheel hub, is smaller than the ordinary axle, so the shaft beam is also shorter from the ground.

Why do low flatbed trailer axles adopt such a shape design? This also starts from its application field and application requirements.

2, low flat trailer axle is mainly used in what field?

Low flatbed trailer axle is a special axle for low flatbed semi-trailer.

Low plate semi-trailer, commonly known in the industry as a large board car, such as 17.5 or 13.75 large board car. According to the announcement, this kind of semi-trailer is specially used for the transport of heavy vehicles, rail vehicles, mining machinery, forestry machinery, construction machinery and other non-removable large goods, and can also be used for the transport of car transport vehicles.

The structure of the low plate semi-trailer is generally a concave beam frame, that is, the front section is a gooseneck, the middle section is a cargo platform, the rear section is a wheel frame, and there is no fence plate around it. When loading and unloading the cargo, the mechanical equipment is moved from the rear wheel frame or the wheel is removed, and then the mechanical equipment is fixed on the semi-trailer.

Compared with other types of semi-trailers, low plate semi-trailers have a lower center of gravity, so the stability and safety in the transportation process is better, and the ability to pass the height limit section is stronger when transporting ultra-high goods.

Low flatbed trailer axles can precisely meet this transportation demand. Because its height from the ground is shorter than other axles, it is more conducive to reducing the center of gravity of the vehicle, improving the stability of transportation, and it is also more convenient for the loading and unloading of goods, helping to improve the passability of the vehicle.

3, low flat trailer axle performance requirements

As a special axle for low flat trailer, low flat trailer axle is different from ordinary trailer axle in terms of performance requirements. Let's first take a look at the relevant technical standards of low flat trailer.

In March 2020, the Ministry of Transport issued an announcement to redefine the technical specifications for low plate semi-trailers. In terms of the outer size limit, the original standard for low plate special semi-trailer requires length ≤13.75m, width ≤3m, height ≤4m, and the new requirement will put the width to 3.4m; In terms of quality parameters, the original standard requires a three-axis low plate preparation quality ≤10t, the new requirements are ≥42t, and the five-axis is ≥55t.

Compared with other types of semi-trailers, the loading capacity of low-plate semi-trailers is up to 140 square meters, which is much higher than the volume of standard van semi-trailers, and even equivalent to the total loading capacity of the front and rear vehicles with mid-axle.

This requires low flat trailer axle in the center of gravity is low, strong passability at the same time, but also have higher strength and load-bearing capacity than ordinary trailer axle, stability is stronger.

Taking DARO low flat trailer axle as an example, its raw material is a high-strength 20Mn2 seamless steel pipe with a higher wall thickness, and the wall thickness is 19mm. The higher the wall thickness, the higher the strength, the stronger the corresponding load-bearing performance, and the transportation stability and safety can be further guaranteed.

In addition, it is the choice of accessories, DARO low flat trailer axle brake drum, brake pads, bearings, hubs, bolts, grease, etc., are heavy duty semi-trailer dedicated to high quality products, whether it is strength, toughness or heat capacity, wear resistance, can better meet the transport needs of low flat trailer.

4, the key process of low flat trailer axle

The production of trailer axles often has to go through a series of processes such as heat treatment, sandblasting, straightening, rust prevention, finishing, welding, etc. Next, let's understand the most critical processes in the production process of low plate trailer axles.

1) One-piece heat treatment molding process

The so-called one-piece axle refers to the shaft beam and shaft head created directly from a complete steel pipe. Generally, through the heat treatment process, the raw material is heated to a certain temperature and maintained to reduce hardness and improve plasticity, and then the shaft beam and shaft head are molded through the molding process, and finally the selected speed and way are cooled.

Different from the traditional "three-piece" axle, the "one-piece" heat-treated shaft head and shaft beam are connected more naturally and strongly, which can fully avoid welding deformation, ensure the accuracy and parameters of the shaft body, reduce the weight of the shaft body, enhance the connection strength of the shaft head and shaft beam, and fully avoid the deformation and bending problem of the axle under high strength load.

2) Automatic quenching and tempering

Quenching and tempering is a common process in steel treatment, and the mechanical properties of steel can be obtained through this treatment, which is a controlled heating and cooling process.

Martensitic structure can be obtained by quenching, although it is hard, but too brittle, so it is often followed by a tempering process after the quenching process, so that it can weaken the brittleness, improve the toughness, and obtain the effect of hardness and toughness.

3) Shaft head grinding and intermediate frequency strengthening

The shaft head is the key part that connects the wheel end parts, and the higher the processing accuracy, the better the performance of the bearings, wheel hubs, brake drums, etc. that are installed later. This precision control is often refined to each borehole or thread.

In addition, the shaft head intermediate frequency strengthening treatment is also essential, especially the bearing connection part, only fully guaranteed strength, in order to ensure that the performance output at high frequency speed is more stable.

4) Finished assembly of trailer axle

This is the most tedious process on the trailer axle production line, involving dozens of parts and hundreds of parts, sometimes even if the torque of a screw tightening is not qualified, it will have an immeasurable impact on the performance of the trailer axle. In order to ensure the quality of the finished product, DARO low flat trailer axle assembly process selected brake drum, hub, bearing and other key components are supplied by domestic strength manufacturers and through multiple quality testing, assembly line automation is high, assembly parameters and parts can be traced, stable and reliable quality, while with long service life, long maintenance cycle, easy maintenance and other characteristics.

5) Finished product quality test

After the completion of the production of DARO low flat trailer axle, it needs to go through batch sampling, pass through the fatigue test bench, salt spray test bench, shaft body magnetic powder inspection platform and other test workshops in turn, and then enter the warehouse after successfully passing, waiting for the subsequent delivery. This is the final step in production and a crucial step in verifying the accuracy and reliability of the product.