What are the three general components of a vehicle suspension?

Vehicle suspension is a device installed between the frame and the axle, which serves as a force transmission connection. It can not only transmit the force and torque between the wheels and the frame, but also buffer the impact force on the vehicle body caused by uneven road surfaces to reduce vibration and ensure smooth driving of the vehicle.

In general, the suspension mainly consists of three parts: elastic components, guide devices, and shock absorbers. Of course, some structurally complex suspensions also come with buffer blocks, lateral stabilizer bars, etc.

1、 Elastic element

It is mainly used to bear and transmit the vertical load and cushion the impact from the road surface. Generally, it can be divided into leaf spring, air spring, coil spring, torsion bar spring, etc.

(1)Leaf spring

Leaf spring is the most widely used elastic element on the suspension of freight vehicles at present. It can be divided into multi leaf springs and few leaf springs. At the same time, it can also serve as a guide device, and it also has a certain damping effect.

The advantages of leaf spring are simple structure, reliable strength, low cost and convenient maintenance; The disadvantages are high self weight, poor comfort, long longitudinal dimensions, which are not conducive to shortening the front and rear suspensions of the vehicle, and the leaf spring pins at the connection with the frame are prone to wear.

(2)Air spring

The main elastic element used in the air suspension is to inject compressed air into a sealed container to realize the elastic effect through the compressibility of the gas. According to the structural type of the airbag, it can be divided into three types: bladder, membrane and composite.

The advantages of air spring are light deadweight, in line with the trend of lightweight, excellent nonlinear elastic characteristics, good shock absorption performance, strong cargo protection ability, and single or multi axle lifting can be realized after the height adjustment device is installed; The disadvantages are relatively complex structure, high cost, poor strength, and cumbersome maintenance.

(3)Coil spring

Spiral springs are generally more commonly used in independent suspensions and are currently standard equipment for most off-road four-wheel drive vehicle suspensions. They are also used on non independent rear wheel suspensions in some high-performance sedans.

Its advantage is that it can provide a larger axle height difference, allowing the loaded wheels to achieve greater up and down travel. It is lightweight, occupies less space, does not require lubrication during use, and is not afraid of dirt. It can also be designed with different diameters and lengths according to different vehicle models; The disadvantage is that the load capacity is certain, and it cannot be adjusted like the leaf spring. In addition, the coil spring can only bear the vertical load, and does not produce friction during deformation, so it does not have the shock absorption effect. Therefore, it must be installed with a guide device and shock absorber.

(4)Torsion bar spring

Torsion bar spring is used in cars, trucks and off-road vehicles. Its advantages are light deadweight, high energy absorption rate, small space occupation and high load capacity. It can absorb more energy than leaf spring or even coil spring. At the same time, it is very compact and does not need additional lubrication; Of course, the drawbacks are also obvious, such as high cost, processing difficulties, and difficulty in popularization.

2、 Guiding device

Used to transmit longitudinal torque, lateral force, and the resulting torque, while maintaining a certain movement pattern of the wheels relative to the vehicle body. According to the basic form of the guidance device, it can be divided into non independent suspension and independent suspension.

(1)Non independent suspension

The structural characteristics of non independent suspension are that the wheels on both sides are connected by an integral axle, and the wheels, together with the axle, are suspended under the vehicle body through suspension. The structure is simple, low in cost, high in strength, easy to maintain, and there is little change in front wheel positioning during driving; The disadvantage is that the seismic resistance and passability are not as good as independent suspension. In general, non independent suspension is more suitable for use in freight vehicles, such as heavy-duty trucks, trailers, and semi trailers. Non independent suspension axles are generally used as load-bearing bridges.

(2)Independent suspension

The independent suspension, also known as the disconnected axle, is connected by a articulated structural join in the middle, and the wheels on both sides can realize relative movement without affecting each other. Its advantages are that it can reduce the installation position of the engine, lower the center of gravity of the vehicle, and have stronger driving stability. While one side of the wheel is bumpy, the other side of the wheel can maintain independence and not be affected, reducing the bumps and vibrations to the body, and making it more passable in complex and harsh road conditions; Its disadvantage is poor load-bearing performance, after all, the lack of a central axle beam structure makes it somewhat inadequate when dealing with cargo transportation.

3、 Shock absorber

The elastic components on the suspension generate vibration after being impacted. In order to improve the smoothness of vehicle driving, shock absorbers are installed in parallel with the elastic components in the suspension to quickly attenuate the vibration of the frame and body.

In general, the three most common types of shock absorbers on vehicle suspensions are hydraulic shock absorbers, pneumatic shock absorbers, and electromagnetic shock absorbers.

(1)Hydraulic shock absorbers.

This type of shock absorber was widely used in the early 20th century, generally known as a double tube structure, also known as a composite tube structure. Its advantages are that it has a long history of development, the relevant technology is relatively mature and complete, the cost is relatively low, and it is easier to obtain damping and large travel. It is one of the most widely used types of shock absorbers in vehicle suspension systems; The disadvantage is that the dual cylinder structure has poor heat dissipation compared to the single cylinder pneumatic type, and the piston area is smaller compared to the single cylinder, so the maximum bearing capacity will be smaller.

(2)Pneumatic shock absorber

Pneumatic shock absorbers are designed with an additional gas chamber than traditional hydraulic shock absorbers, usually filled with nitrogen inert gas. It is worth noting that the working medium of pneumatic shock absorbers is not entirely gas, and the main cylinder is still filled with oil, with only a portion of gas present in the air chamber. Traditional oil has high viscosity and can provide efficient vibration attenuation, but the response speed is not fast enough. After the combination of oil and gas, it can fully compensate for the weakness in response speed and quickly achieve shock absorption effect.

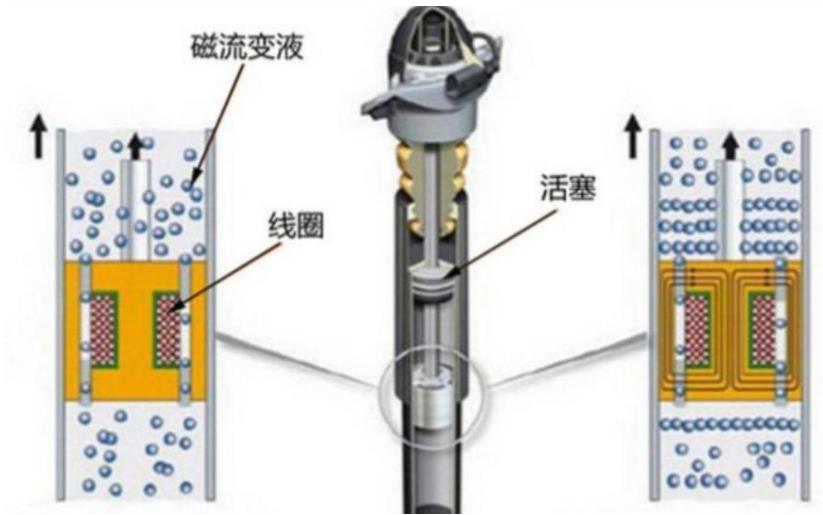

(3)Electromagnetic shock absorber

Electromagnetic shock absorbers are a type of active shock absorber that can obtain signals from the vehicle's ECU, change damping in real-time, and control the stiffness and flexibility of the suspension. Theoretically, the ECU can control the electromagnetic shock absorber to change the damping value 1000 times within 1 second, and the shock absorption effect can be imagined. Of course, the price is never cheap.

As one of the main models in the logistics and transportation industry, trailer suspension must meet the strength standards while providing shock absorption performance.

In general, ordinary trailers can choose leaf spring non independent suspension, which has strong reliability, low price, and convenient maintenance;

For standard load transportation with high requirements for cargo damage or sensitive to vehicle weight, air type non independent suspension can be selected, which has light weight and good shock absorption effect;

Trailers that frequently run heavy loads can also choose single point non independent suspension, which has stronger load-bearing capacity than ordinary leaf spring suspension;

If the car owner's budget is sufficient and the suspension requirements are high, in addition to minimal cargo damage, light weight, and good shock absorption, stability, load-bearing capacity, and longer maintenance cycles are also required. Alternatively, hydro-pneumatic suspension can be chosen, which can achieve the shock absorption effect of air suspension while also taking into account the use needs of load-bearing capacity and complex road conditions.