What are the components of the rear axle of a semi-trailer?

Trailer axle is a typical support bridge, the main role is load-bearing, used to bear the weight of the body, and then can ease road bumps, ensure vehicle braking, maintain vehicle driving, etc., does not have steering or driving function.

From the braking mode, the rear axle of semi-trailer can be divided into two types: disc type and drum type. From the point of view of processing technology, the rear axle of semi-trailer can be mainly divided into two categories: American and German; From the perspective of the applicable models, the rear axle of the semi-trailer can be divided into low flat trailer axles, three-line six-axles, single/twin tire trailer axles, special trailer axles, etc.

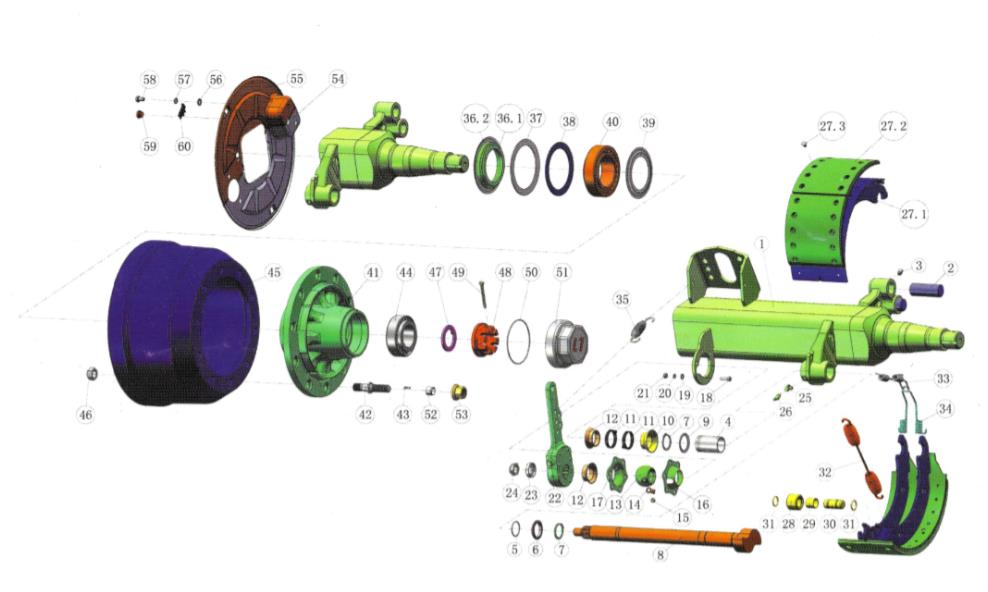

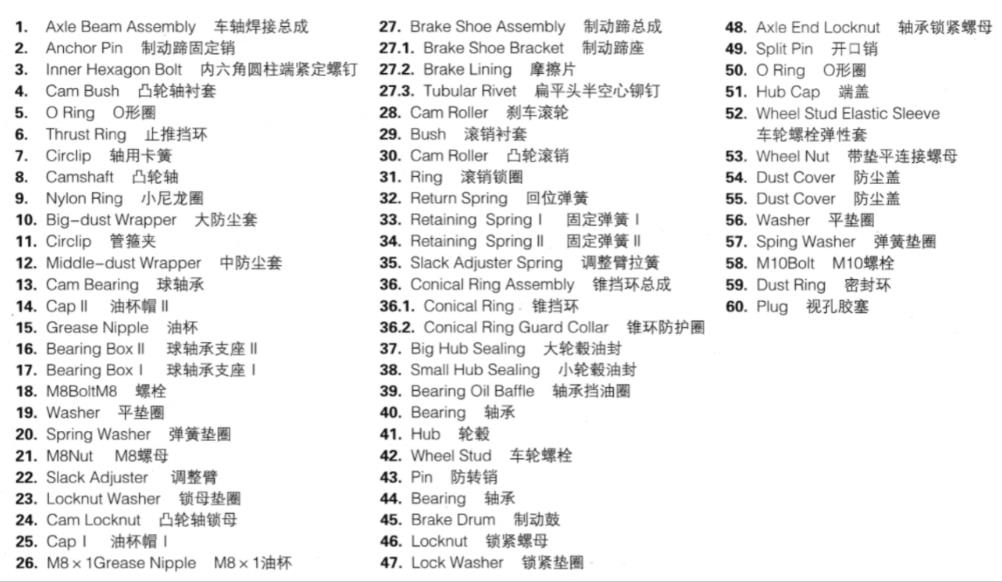

Although there are many types of rear axle of semi-trailer, the structure is basically different, and it is composed of the total composition of shaft body, brake assembly, wheel end assembly and other components. What are the detailed parts of the rear axle of the semi trailer? The following takes DARO drum trailer axle as an example to show you in detail:

This drum trailer axle belongs to one of the German series, which is more intuitive from the axle head and fully conforms to the appearance characteristics of the German axle. As can be seen from the figure above, there are 60 types of parts on one end of this axle, among which we are more familiar with such as friction plates, brake drums, wheels, bearings, etc., usually when doing maintenance contact is more, in addition to a variety of gaskets, spring, pins, supports, bolts, etc., large and small parts, from material and quality to installation standards and technology, All related to the performance of the axle.

How is the rear axle of the semi-trailer processed?

Taking this drum trailer axle from DARO Group as an example, let's start with raw materials. The axle of this trailer is selected 20Mn2 high-strength alloy seamless steel pipe with a wall thickness of 11mm, and the quality test is qualified, and the production process is officially entered.

1. According to the drawings, cut the steel pipe into a length that is convenient for processing;

2, into the hot rolling process, through the heat treatment process of up to 1300℃, the steel pipe to create a shaft beam prototype;

3, according to the drawings of the shaft part of the processing to ensure the subsequent processing size;

4, through the cold push square process, the shaft tube is processed from round to square;

5, quenching + tempering, improve the hardness, strength and toughness of the shaft tube;

6. Shot blasting and sandblasting, clean up the oxide and oil after heat treatment, improve the finish of the shaft tube;

7. Straighten the axle to further improve the accuracy of the axle;

8, primer spraying, providing isolation, moisture-proof, anti-oxidation and anti-corrosion effect, improve the adhesion of subsequent top paint;

9. CNC machine tool processing, finishing the shaft head position to ensure the shaft head accuracy;

10, the bearing and shaft beam connection part of the medium frequency induction strengthening treatment, enhance the strength of the shaft head, to ensure the stable performance of the shaft head and bearing under high speed;

11, check the size and thickness of the shaft head, and apply anti-rust oil after acceptance;

12, spray paint, with primer, to protect the shaft from erosion;

13, install shaft nut locking gasket, welding brake plate, spherical bearing, air chamber seat;

14, sampling of semi-finished products, millions of anti-fatigue test qualified, into the assembly link;

15, on the basis of semi-finished products, install wheel hub, brake drum/brake disc, internal and external bearings and other parts.

16, enter the finished product quality inspection link, the finished trailer axle quality inspection.

17, after passing the quality inspection, enter the finished product warehouse, arrange the delivery according to customer needs.

The above is the complete production step of the trailer rear axle from raw materials to the finished product, which is executed under a unified production standard. Even if a screw is screwed to what Angle and what degree of tightness, there are relevant standards and specifications. Only when each process is strictly checked can the final quality of the finished product be guaranteed.

From this point of view, when owners choose trailer axles, they still try to choose brands that have their own production workshops. Why do you say that? Although there are many trailer axle brands on the market, some of them do not have the production capacity, you need to buy semi-finished products from other factories, you only need to assemble it yourself and attach your own brand identity, although the process is much simpler, the overall grasp of product quality is correspondingly smaller. If there are conditions, it is still recommended that the owners do the corresponding inspection work before the purchase, and try to avoid the problems and troubles in the subsequent use.