What are the common types of car transport vehicles?

Car transport vehicles refer to vehicles that specialize in the transportation of cars, commercial vehicles, exhibition vehicles, and experimental vehicles. Whether it is buying a car in another place, using a car in a different place, or "packing and sending" a passenger car during travel, it can be realized by a car transport vehicle .

The development of sedan logistics is closely related to the development of the automobile industry, and the production and sales of automobiles directly affect the market demand for sedan logistics. With the rapid development of my country's automobile industry, my country's demand for car logistics is showing a trend of rapid growth.

Common semi-trailer car classification:

1. Single axle twin tires

This model is designed with 1 axle, which can hold 4 tires. It has low cost, moderate carrying capacity, and large space in the middle of the lower layer. It is especially suitable for mixed cars and SUVs.

The disadvantage is that the height of the bearing surface at the tire is slightly higher.

2. Double axle single tire

2 axles are designed, which can hold 4 tires. One axle can only hold 1 tire on each side. The chassis is relatively low. Starting from the rear end of the gooseneck, the entire lower middle space is large, suitable for loading minivans and SUVs and other models.

However, affected by the width of the vehicle and the width of the tires, the inner width of the vehicle body at the tires is relatively small, and it is relatively difficult to pass through when loading wide-body vans and SUVs.

3. Twin-axle twin tires

This is a type of vehicle that is widely used in vehicle transport semi-trailers at present. It is designed with 2 axles and can be installed with 8 tires. Models such as minivans and SUVs.

From a structural point of view, there are two forms of twin-axle twin-tire transport semi-trailers:

The upper and lower layers are flat-mounted, which can load 6 commercial vehicles;

The lower layer adopts one or two aircraft springboards, which can load 7 vehicles.

4. Long head tractor + semi-trailer

The total length of the long-head tractor + semi-trailer is 1m longer than that of the flat-head tractor + semi-trailer, and the longest can reach 18.1m. A vehicle platform can be installed on the upper part of the long-head tractor, and one more vehicle can be installed, and the total number of vehicles can reach 8, and the loading performance is significantly enhanced.

It is worth noting that although one more vehicle can be loaded, its actual length is only extended by 1m, so the semi-trailer used with the long-head tractor must be specially designed, the front column must be lowered or moved backward, and the upper layer must be loaded overlapping , otherwise it cannot meet the demand for loading 4 vehicles on the upper layer.

In addition to the semi-trailer type, GB1589 has added a center-mounted axle car transport train. According to the announcement period, the length can reach up to 22m, which is nearly 5m longer than the total length of the semi-trailer train and nearly 4m longer than the long-headed semi-trailer train. The length advantage very obvious.

At present, the structures of the center-mounted axle car carriers developed by various manufacturers are not the same, and they are generally divided into the following categories:

1. Column bearing type:

The front vehicle and the trailer each have four uprights for load bearing, and there is no roof longitudinal beam on the side of the body, which is convenient for loading.

2. Body side frame bearing type:

The pillars, top longitudinal beams and side beams form an integral bearing, the stability of the vehicle body is good, the force on the front and rear of the pillars is dispersed, and the structural strength is good.

3. Rear column oil cylinder + movable swing rod type:

The structure of the body is simpler and the loading is more convenient, but the rear end of the upper platform shakes more from side to side. In order to improve the stability, the root of the movable swing rod needs to be strengthened.

Advantages of the center-mounted axle car transporter:

1. Economic benefits. Ordinary standard semi-trailer car carriers can transport 6 cars, long-head tractors can transport 7 cars, and center-axle car carriers can transport 8-10 cars, with obvious economic benefits;

2. Functional advantages. The center-axle car transporter can be used as a train, or it can be used as a single car without the trailer, which is more convenient when transporting fewer vehicles in urban areas or short distances;

3. Flexibility advantage. The chassis and center of gravity of the center-axle car carrier are lower, and the turning radius is smaller under the same vehicle length.

Disadvantages of center axle car transporter:

1. The purchase cost is higher. Compared with ordinary trucks or semi-trailers, the purchase cost and maintenance cost of center axle trailers are higher.

2. Poor driving stability. The center axle wheel is in the middle of the carriage, so the body is easy to swing up and down or left and right when running. In addition, its connection point with the main car is under the frame. When the speed is too fast or the road is slippery in rainy days, it is easy to flick, lose control, and roll.

3. High requirements on road conditions. Although the low chassis provides better passability and stability, the adaptability to bad road conditions has deteriorated.

4. Driving is difficult. In practical applications, many car owners have reported that center axle trailers are "difficult to turn", "keep shaking when driving", and "require a little skill to drive".

Although there are problems, it can be seen from the current general trend of the domestic transportation industry that modularization and standardization are the general trend. With the advancement of technology and the continuous improvement of related supporting facilities, the shortcomings of central axle trailers may be gradually overcome.

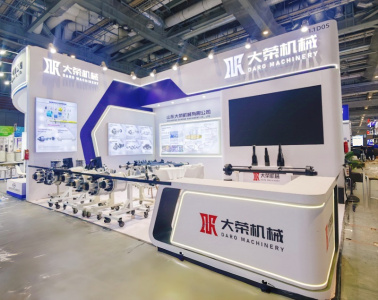

DARO Group is one of the earliest companies in China to start mass production of integrated axles. It has been deeply involved in the trailer axle industry for more than 20 years, and its craftsmanship, technology, experience, and strength are all in the forefront of the industry. ) is specially designed and built for car carriers. While ensuring the load-bearing capacity, it lowers the vehicle chassis and center of gravity to a greater extent, improves vehicle stability, expands the loading space of the cargo platform, and provides convenience for vehicles to get on and off.