What are the common types of trailer axles?

The trailer axle is a typical driven axle, its main function is load bearing and auxiliary braking. Compared with the drive steering shaft, the structure of the trailer axle is relatively simple, mainly composed of axle body assembly, brake assembly, wheel end assembly, camshaft assembly and other components.

From a structural point of view, common trailer axles are mainly divided into the following types:

1. Drum trailer axle

The drum trailer axle is the most widely used trailer axle in the domestic market. The main feature is the 360° sealed brake drum, which has a large braking friction area and stronger and more sufficient braking force. It can be applied to various General cargo transportation.

Drum trailer axles can be divided into two types: American and German:

American-style trailer axles are relatively affordable, simple in structure, and the accessories are common in the industry. They are easy to buy and match, and the maintenance is more convenient. The design is more inclined to heavy loads, and the cost performance is high. It is more suitable for sand and gravel, steel coils, wood, coal and other goods. transportation;

The advantages of German-style trailer axles tend to be lightweight and long-lasting. They are lighter than American-style trailer axles in terms of dead weight, which can save fuel. They are designed to withstand high temperatures and have less tire damage. The maintenance cycle has also been extended to a certain extent. Suitable for standard long-distance transportation.

When it comes to the maintenance cycle, we have to mention the maintenance-free trailer axle.

The maintenance-free trailer axle is also a kind of drum trailer axle, but the lubricating grease is replaced with lubricating oil to achieve long maintenance. The longest maintenance cycle can reach about 80W kilometers, which is more suitable for vehicles with high requirements on vehicle attendance and transportation timeliness Working conditions, such as port drop-and-hook, logistics, green traffic, cold chain transportation, etc., of course, the price is also higher than that of ordinary trailer axles.

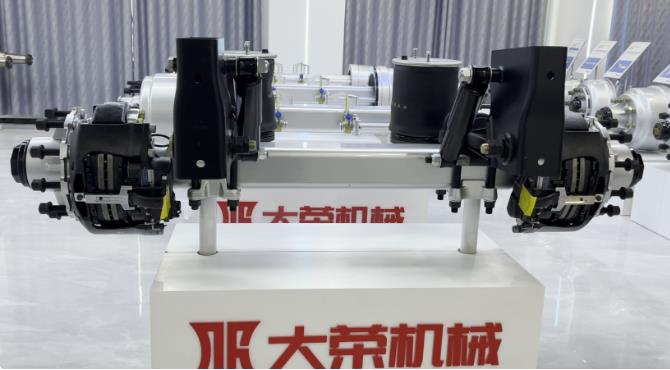

2. Disc trailer axle

In recent years, the application rate of disc trailer axles on semi-trailers is getting higher and higher. On the one hand, it is closely related to regulations and policies, and on the other hand, it is also linked to its own characteristics.

The disc trailer axle replaces the brake drum with an exposed brake disc, and the heat dissipation, thermal attenuation resistance, and water attenuation resistance have been greatly improved. In addition, its brake transmission components have also been optimized, the brake pads can be driven immediately after stepping on the brakes, and the braking response speed is fast, especially when used in conjunction with ABS, EBS, hydraulic retarder, air suspension and other devices, it can Let their respective advantages be brought into play to the greatest extent, and jointly provide high-quality performance guarantee for the vehicle.

In general, the axles of disc trailers are mainly used in the transportation of dangerous goods, precision instruments, valuables, flowers, fruits and vegetables, etc. Of course, the three-axle fence and warehouse fence vehicles clearly required by regulations must also be equipped with disc brakes.

3. Low-bed trailer axle

The low-bed trailer axle is a special trailer axle for low-bed semi-trailers, which is what we often call a gooseneck trailer, and it mainly transports large cargo that cannot be disassembled.

Compared with ordinary trailer axles, the diameter of the wheel end of the low-bed trailer axle is smaller, which can provide a lower height from the ground, which is convenient for loading and unloading of goods, and also reduces the center of gravity of the vehicle, improves stability, and can be larger when encountering high-limit road sections. Improve the passability of vehicles to the greatest extent.

In addition, the axle body and accessories of the low-bed trailer axle are all dedicated to heavy-duty transportation. The wall thickness is higher, the strength is higher, and it is more durable. It is almost impossible to transport machinery and equipment, large tanks, construction equipment, power station equipment, etc. Down.

4. Three-wire six-axis

It is specially used for the three-line six-axle semi-trailer for the transportation of large and oversized goods. In addition to the three-wire six-axle, four-wire eight-axle, five-wire ten-axle...and so on, all belong to the multi-axis heavy-duty semi-trailer, and the trailer axle used also belongs to the multi-axis trailer axle.

The diameter of the wheel hub of the three-line six-axle is also relatively small, which is similar to the axle of the low-bed trailer, but the number of tires on the three-line six-axle semi-trailer is more. A three-line six-axle can hold 12 sets of wheels, which can increase the contact area between the tire and the road. , so as to reduce the average pressure of the wheels on the road surface and protect the road surface from damage. Therefore, the three-line six-axle semi-trailer can bear 80t on high speed, and the load-bearing tonnage of four-line eight-axle, five-line ten-axle and other models is higher.

5. Recessed trailer axle

Also called eccentric trailer axle, the most obvious feature is that the axle body and the axle head are not on the same straight line, a bit like an overturned portal trailer axle:

This design can reduce the chassis and center of gravity of the vehicle to a greater extent, improve the stability of the vehicle, expand the loading space of the cargo box, and provide convenience for loading and unloading of goods, but at the same time, the requirements for road conditions are further improved.

Recessed trailer axles are generally used more on car carriers in China, and some foreign trailers that have requirements for vehicle chassis and center of gravity are also used more.