Truck maintenance should not spend a few sums of money, careful to be fooled

For freight drivers, the vehicle is not only a means of transportation, but also a profit-making partner, most of the time to eat and live in the car. As the saying goes, "the work must be good first", especially the freight vehicle to undertake the transportation task is relatively heavy, heavy load, long road, high attendance, more need to do maintenance on time, so as to effectively extend its service life, "three points repair seven points maintenance" is this truth.

Generally speaking, the truck is usually recommended to maintain 5,000 kilometers once, while replacing the oil and three filters, about 20,000 kilometers to replace the gear oil, four wheel maintenance half a year, the brake system is adjusted half a month, check the tire pressure every week, clean the debris on the tire. In addition, the consumption parts of the vehicle should also be replaced on time, such as brake pads, wipers, tires, batteries, brake oil, trailer axle conveyor belts, circuit oil systems, etc.

Many owners will send the vehicle to the service station to do maintenance, often will be listed a long list of maintenance projects that seem to be worth spending money to do, the cost is often hundreds or even thousands, but in fact, some projects may not be so necessary, and even there are certain side effects, of course, these things service station personnel will not be clearly informed. Today, DARO trailer axles will simply take stock of the maintenance items that are slightly suspicious of IQ tax.

1. Turbine maintenance

The so-called turbine maintenance is actually to clean the turbocharger and clean the impurities and dust on the blades. The cleaning method is generally to inject the cleaner into the turbine inlet end and clean the inner wall of the turbine inlet end by soaking or rinsing.

In fact, the air inhaled by the turbocharger is originally filtered by the air filter, which is not as dirty as imagined, just like the purified water that has been filtered, there is no need to filter it again. As long as the vehicle changes the oil, oil filter and air filter on time, there is no need for additional turbine cleaning.

2, tire maintenance

Whether the tire maintenance needs to be done depends on what the specific operation content is. If the recommended tire maintenance content of the store includes checking whether there is improper assembly of the tire, whether there is friction between the tire spring, fender, and the carriage, whether the tire pressure is normal, whether there is wear on the tire surface, cleaning the stone and other foreign bodies inside the pattern, then this maintenance project can be done, and even completely necessary.

In fact, the tire maintenance recommended by most service stations refers to tire washing, stain cleaning, tire wax, and the appearance of the tire does look new after completion, which can have little impact on the actual performance. Of course, if the owner is particularly concerned about the appearance of the tire, it can also be done.

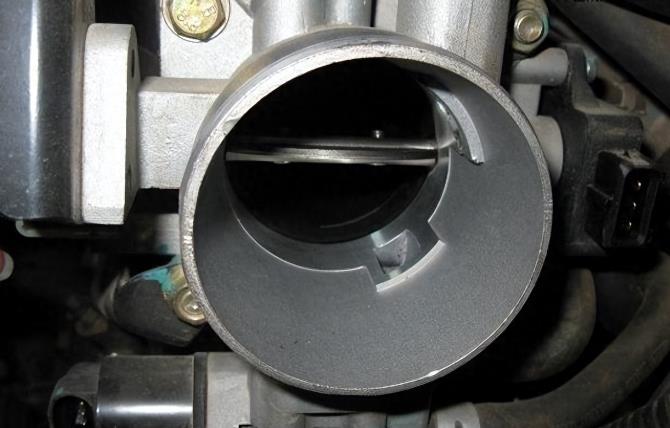

3, throttle clean

Throttle is a controlled valve that controls air into the engine, once it fails or is damaged, the epc light on the instrument will be lit, and the vehicle will appear unstable or no idle speed, engine starting difficulty, vehicle jitter and other phenomena, one of the most common reasons for throttle failure is the throttle dirty.

That is to say, when the instrument failure light is not lit, the throttle does not need to be cleaned. Then the owner said: I clean it can also prevent the throttle failure. The truth is true, but the premise is that the throttle cleaning will not cause side effects. At present, there are two main ways to clean the throttle valve, one is to remove the throttle valve for cleaning, and the other is to spray the cleaner into the throttle valve after cleaning the impurities are discharged by three-way catalysis. No matter which kind, cleaning a throttle, in addition to spending money, is a damage to the throttle and the engine. Therefore, if the vehicle can be used normally and the throttle failure light is not displayed, it is not recommended to clean the throttle.

Some owners said: After I cleaned the throttle valve in the shop before, the vehicle did work well. In fact, this is not necessarily because the throttle cleaning is done, because the throttle cleaning is generally done in sets with oil circuit cleaning, oil replacement, etc. In other words, if the throttle is not faulty, the cleaning or not cleaning, there is no difference in use.

4. Clean up carbon deposits

Speaking of the problem of carbon accumulation of vehicles, a series of searches on the network, the title is "old driver revealed" "repair factory insider", and finally found that the original is to sell cleaning agents. At present, the problem of vehicle carbon accumulation can not be completely avoided, if too much carbon accumulation is easy to affect the performance of the engine, so the vehicle carbon accumulation still needs to be cleaned, but the number of cleaning does not have to be as frequent as the service station said.

Under normal circumstances, the vehicle carbon deposition of trailer axle about 20-40,000 kilometers can be cleaned once, and excessive cleaning will cause a series of side effects, such as blocking three-way catalysis.

5. Additives with different functions

In some service stations, the staff will also recommend a variety of additives, such as engine anti-wear agents, oil additives, oil reinforcing agents, etc., sounds unclear and severe, of course, the price is also very beautiful. But is it really necessary?

Not at all. For example, oil additives are said to be anti-wear, anti-corrosion, and have a certain cleaning effect. In fact, the oil we use is originally composed of base oil and additives, the proportion of additives is generally not more than 20%, the role is nothing more than clean dispersion, extreme pressure anti-wear, corrosion and rust, anti-oxygen anti-foam, improve fluidity and so on. That is to say, if the oil really needs to have additional functions, the oil has already added a certain proportion of these additives when it leaves the factory, and there is no need to spend money to buy it separately. Instead of spending money on these additives, it is better to save money to buy better oil, which is more reliable.

After saying the maintenance projects that can not be done, let's talk about those common vehicle maintenance errors:

1, oil only add not change

Oil is essential in the use of diesel engine, owners generally do not forget to check the amount of oil in the lubricating oil and add according to the standard, but it is easy to ignore the quality of the oil and the replacement of the deteriorated oil, or to save time in the replacement without cleaning the oil circuit, which will affect the use of oil.

2. Indiscriminate use of grease

That is, commonly known as butter, mainly plays the role of lubrication and sealing, but once excessive use will backfire. In addition, some people like to apply butter on the cylinder pad and tire nuts, thinking that they can improve sealing and prevent rust, but they do not know that doing so will affect the performance of the vehicle, and even lead to vehicle accidents in serious cases, so the butter must not be spread, wipe.

3, tire pressure is too high

Tire inflation pressure is an important factor to determine its service life and work efficiency. Too high or too low tire pressure will affect its service life, but also not conducive to safe driving. The scientific inflation standard should be based on the standard pressure of the tire, and with the change of temperature, the tire pressure is slightly adjusted.

4. The bolt is too tight

The torque of the bolt is generally more stringent, such as the transmission box, cylinder head, tires, connecting rod and axle parts, tightening torque in the manual are set up special provisions, some owners in order to prevent the loosening of the bolt, deliberately screw it particularly tight, in fact, this is wrong, because screw too tight easy to cause the screw or bolt break, may also lead to the slide caused by failure.

5. Polish the bearing shell with gauze

Because the scraping technology is difficult to master, some repairmen will replace the scraping tile with emery cloth when replacing the bearing shell. This method is highly advisable in actual maintenance, because the abrasive particles on the emery cloth trailer axle are harder than the bearing shell alloy, and the sand particles are easily embedded in the alloy when grinding, shortening the service life of the crankshaft.

6, piston open fire heating

Because the piston and the piston pin are interference fit, so in the installation of the piston pin, should first make the piston heat expansion, some maintenance personnel will put the piston on the open fire direct heating, which will lead to the piston parts of the thermal expansion and contraction degree is inconsistent cause deformation, its service life will be significantly shortened, so it should be placed in the hot oil evenly heated, so that it slowly expand.

7, water tank boiling directly add cold water

When the water tank is boiling, if the cold water is added immediately, it will cause the cylinder head and cylinder block to crack, so emergency measures should be taken to stop the operation, so that the engine cooling water can cool itself.