Trailer lightweighting has become an industry trend, how to safely achieve lightweighting of trailers?

With the strengthening of traffic management departments on overload transport control, vehicle lightweight gradually become an industry trend, more and more vehicle owners in the purchase of trailers and accessories, more inclined to choose those stable performance but their own weight lighter products, which also to a certain extent promote the trailer, accessories manufacturers in materials, technology, structure and other aspects of continuous optimization and improvement.

In general, the trailer wants to achieve light weight, the common way are the following.

1, reduce the thickness of the plate, choose high steel standard, high strength, good toughness steel.

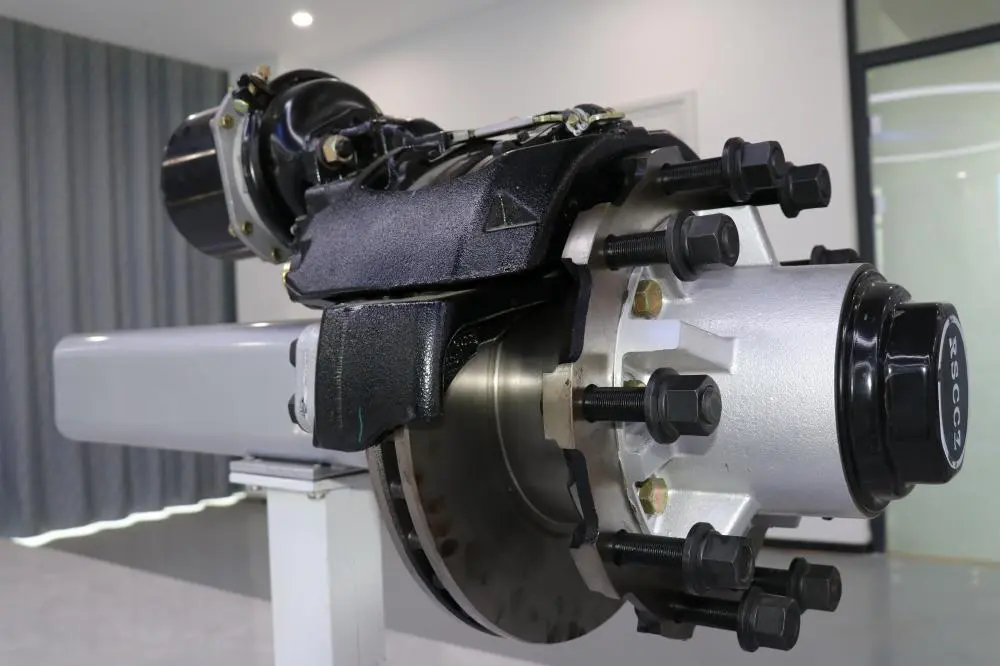

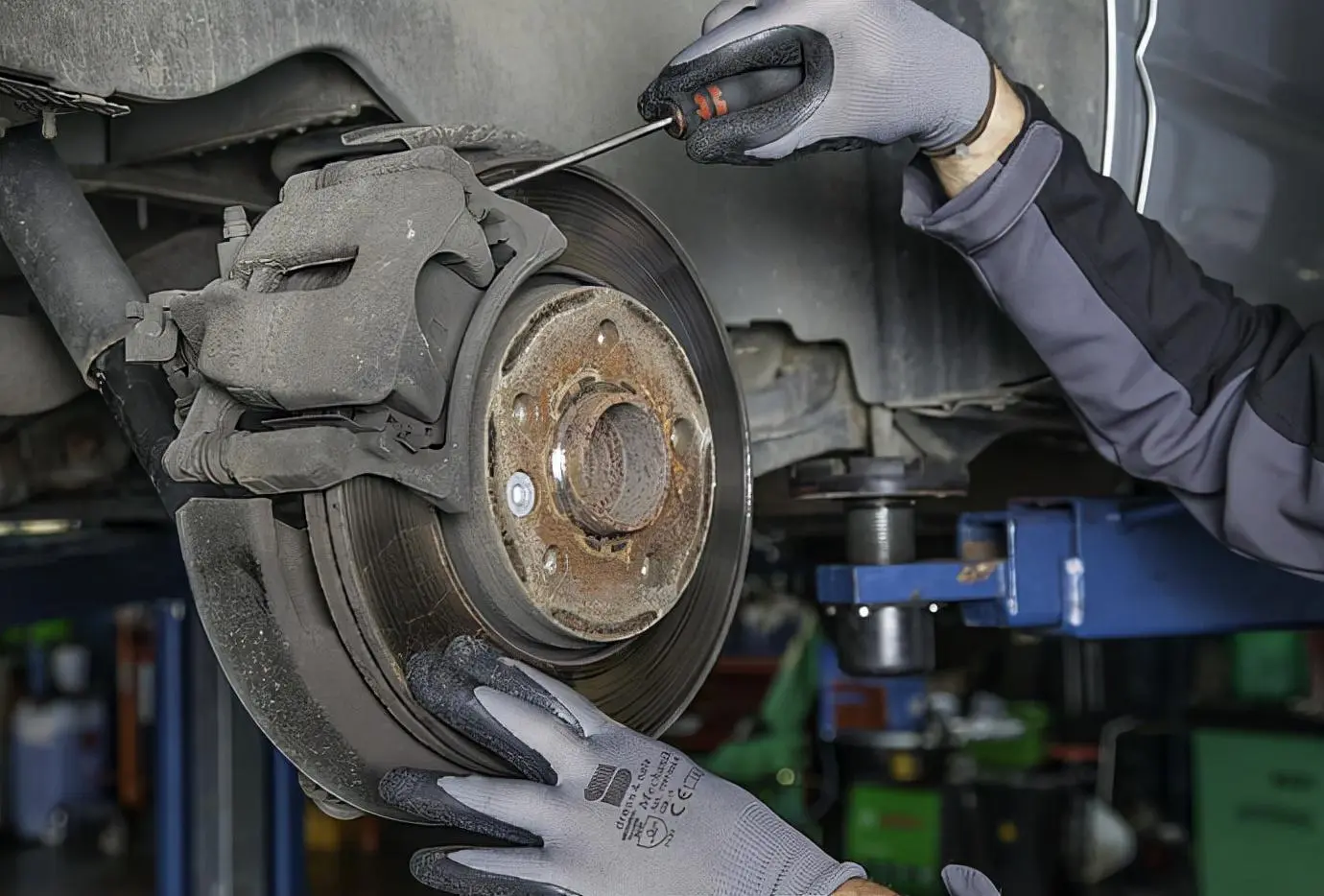

2, reduce the weight of the axle, take light bridge, disc brakes and other measures.

3, the choice of lightweight beam, such as the use of shaped punch, reduce the height of the vertical plate and the upper and lower wing width.

4, choose a lighter weight suspension system, such as air suspension.

5, the use of suspension rear axle, when not in use can be lifted.

6、Reduce the weight of accessory parts, such as bumpers, protective nets, spare tire racks, tool boxes, tarp racks, etc.

7, double tires for single tires, such as some manufacturers use a large single tire, weight reduction is also very considerable.

Reasonable lightweight design or improvement can effectively reduce the weight of the trailer itself, increase the owner's choice of cargo weight or cargo type, but also reduce fuel consumption, energy saving and environmental protection at the same time to improve transport efficiency.

However, we should also see that, although lightweight is a major industry trend, but must be safe as a prerequisite. Especially trailer vehicles, as the main force of cargo transport, in the load-bearing performance and transport safety requirements are higher, so in the lightweight must be fully considered the actual, to ensure the safety performance of the premise of lightweight improvement, if the simple pursuit of "light" at the expense of safety, it will not be worth the loss.

For example, the weight reduction of axle in the light weight path mentioned above. We all know that the axle is the main part of the trailer load-bearing, connected to the body through the suspension, supporting the weight of the body, while the load-bearing force will be distributed to each tire to ensure that the trailer driving.

As a load-bearing parts, the realization of lightweight design is not simply a change of material can be solved, especially in ensuring that its load-bearing performance is not reduced or even enhanced under the premise of achieving its own weight reduction, it is not an easy task.

Some unknown small manufacturers, in the R & D capabilities, production technology, manufacturing technology and other aspects are not strength support, simply using the rough to achieve lightweight, such as reducing the amount of steel or the use of toughness is not up to standard light steel, so that the production of axles, although from the appearance of no obvious difference, even in the weight advantage is obvious, but once put into use, with the passage of time, in the high strength Once put into use, over time, in the high strength of gravity and changing road conditions is easy to metal fatigue, bending, cracking and even twisting, a serious threat to operational safety.

Therefore, when car owners choose lightweight products, they should not blindly believe in the words of the advertisement, but also compare them with other products and do more research, only products that can withstand the test of the market and users can guarantee the safety of travel. For example, the Da Rong Group production of lightweight axles, the choice of 20Mn2 high-strength alloy seamless steel pipe, from raw materials to ensure strength, toughness and light weight, while with a piece of heat treatment molding technology, integral axle casting, powder coating + electrophoresis process, brake base plate after welding three holes boring finishing, CNC processing of the axle head, medium frequency induction treatment and more than a dozen processes, in order to improve the axle load-bearing, extend the axle Under the premise of improving the axle load capacity and prolonging the life of the axle, taking into account the lightweight, compared with the traditional axle weight reduction of 15%-20%. The finished products are tested before leaving the factory to ensure the quality is up to standard, stable and reliable.