Trailer chassis maintenance needs to pay attention to these four systems

The chassis is the basis of the overall shape of the vehicle, providing driving, steering and braking forces for the use of the vehicle to ensure the normal running of the vehicle. In the maintenance work of the vehicle, the chassis is also a very important part, especially the owner who has not done anti-rust treatment, but also need to do chassis maintenance.

Structurally, the vehicle chassis is mainly divided into four major systems:

1. Transmission system: mainly includes clutch, transmission, universal transmission, main reducer, differential and half shaft.

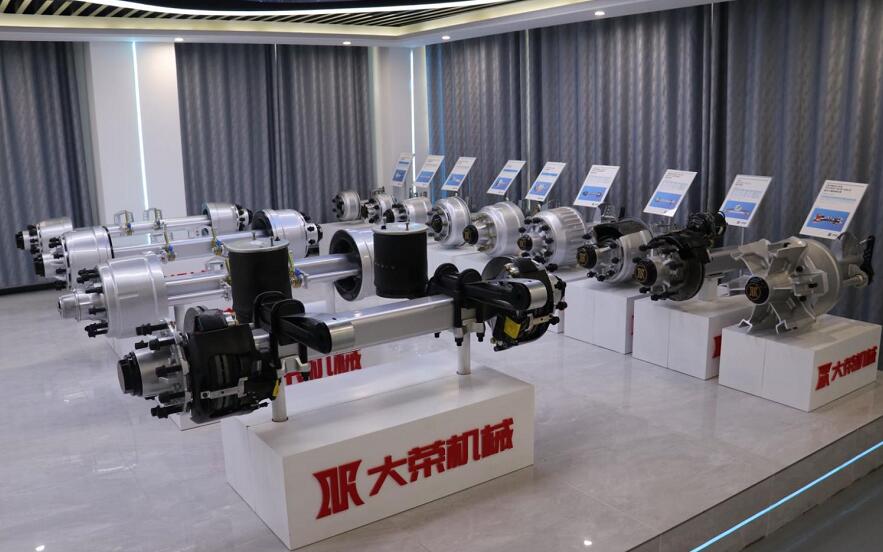

2, driving system: trailer axle, frame, suspension, wheels, etc.

3, steering system: steering wheel, steering shaft, steering column, etc.

4. Brake system: mainly composed of energy supply device, control device, transmission device and brake.

Normal maintenance needs to start from the above four systems:

1. Transmission system

Transmission system maintenance, first of all to check the variable speed tank, check the oil quality and oil level, if there is a change, need to replace or add in time.

Note that the transmission bearing also needs to add lubricating oil.

In the process of maintenance, it is also necessary to check whether the dust jacket is damaged, and replace it in time if it is damaged.

Check the oil quality and oil level of the reducer, add and replace the right amount, so that it is in a closed state to avoid oil leakage.

In the process of seasonal maintenance, especially in winter and summer, the use of oil is not the same, and special attention should be paid to the oil concentration. Under normal circumstances, the viscosity of the oil will change with the temperature, try to choose the oil with lower viscosity in winter, and choose the oil with higher viscosity in summer, so that the engine can be used more smoothly.

It is worth noting that when refueling the vehicle in winter and summer, it is also necessary to control the amount of oil, when the oil alarm light or oil pressure gauge is bright, you should find the right place to stop and check the amount of oil, if the amount of oil is insufficient, you need to add it in time. Pay attention to add the correct oil according to the model of the car, do not mix and add, so as to avoid a large amount of mixed liquid remaining in the gasoline tank, forming carbon deposits.

2. Driving system

It is necessary to check whether the tightness of the hub bearing is appropriate, whether the positioning of the front wheel is accurate, and whether the tire pressure meets the standard.

Too tight hub bearing will increase the friction of wheel rotation; If it is too loose, the wheel will easily skew or swing during driving. It is recommended that the owners regularly go to the professional repair shop to check and adjust the tightness of the wheel to maintain the best condition of the wheel.

Front wheel positioning can ensure that the wheels of the vehicle are in a pure rolling state while driving, and maintain the smoothness of the vehicle and the portability of the steering. If the front wheel positioning is not accurate, it is easy to cause the front wheel to roll in the use of the vehicle, improve the wheel wear, and increase the friction resistance between the vehicle and the ground, resulting in poorer sliding performance and increased fuel consumption. The owner can usually go to the professional repair shop for four-wheel positioning.

The air pressure of the tire is best adjusted according to the weather and road conditions.

3. Steering system

Steering fluid is often in a continuous extreme pressure and high temperature working environment, prone to pollution degradation and loss of lubrication performance, the formation of paint film and other deposits, resulting in vehicle steering difficulties, steering wheel shaking and so on. If the sediment can not be removed regularly, it is easy to cause damage to the hydraulic pump in the system, resulting in high maintenance costs.

Steering system maintenance mainly includes the following points:

When driving on pothole road, slow down to reduce the load borne by the steering machine;

Check the status of the dust jacket once a month, if the sheath is found to be damaged, it must be replaced immediately, and do a comprehensive inspection and maintenance of the steering machine before replacement;

In the four-wheel positioning adjustment before the bundle, change the steering rod, pay special attention to the protective sleeve can not appear distortion, assembly is not in place and other phenomena, otherwise it is easy to cause damage to the sheath;

Every 100,000 kilometers or so should do a comprehensive maintenance of the steering machine, comprehensive cleaning, re-grease;

The use of the steering machine is bad, the load is large, must use special grease, ordinary grease can not meet the use requirements;

The clearance of the steering machine will gradually increase in use, if the left and right empty travel of the steering wheel exceeds 15 degrees, the steering machine must be checked, such as the rack and pinion abnormal wear is serious, the steering assembly must be replaced, if there is no abnormal wear, but the clearance is too large, you can adjust.

4. Brake system

Good braking performance is the guarantee of safe driving. If the vehicle is found to have braking deviation or reduced braking effectiveness, it must be repaired or replaced at the maintenance point in time. For safety reasons, it is best to test the brake in advance before driving to ensure that there is no anomaly before starting.

Now the weather turns cold, how to do the maintenance of the brake system?

Winter temperature is low, the sealing ring or cushion is relatively hard, easy to lead to the contraction of the sealing pipe joints, before the car must check the sealing of each joint of the gas path, it is best to touch it again, tighten it in time or reinstall it.

Check the main vehicle dryer tank to ensure that the main vehicle air supply is dry and no moisture.

In winter, the temperature is mostly below zero, and the gas is easy to produce water droplets, so the main vehicle and trailer air storage tank need to regularly release water to ensure the dry gas used by the brake. If the water is not released in time, the wet gas inside the air reservoir is easy to enter the valve body, and ice occurs when the temperature is below zero, resulting in the piston sticking and affecting the braking performance.

When ABS connects multiple sensor joints, it is necessary to check and maintain each sensor joint. At the same time, the ABS gear ring should be removed and cleaned regularly to ensure that the sensing signal of the gear ring and the probe is good, and the joint is free of putty.

In order to ensure the stable braking performance of the trailer, in addition to the daily maintenance and maintenance of the braking system, it is also very important to choose a trailer axle with good quality and stable performance. The higher the quality of the trailer axle, the more sensitive and reliable its braking performance, which can provide protection for driving safety in cold weather.