Teach you to repair 18 common tire problems in trailers

Trailer as a freight vehicle, its transport conditions are relatively complex, especially for tires, as the only part of the trailer in contact with the road, need to bear a variety of deformation, load, force and high and low temperature under high-speed, heavy load, rain, snow, sand and other conditions. Therefore, the tire loss rate of the trailer is generally much higher than that of the passenger car.

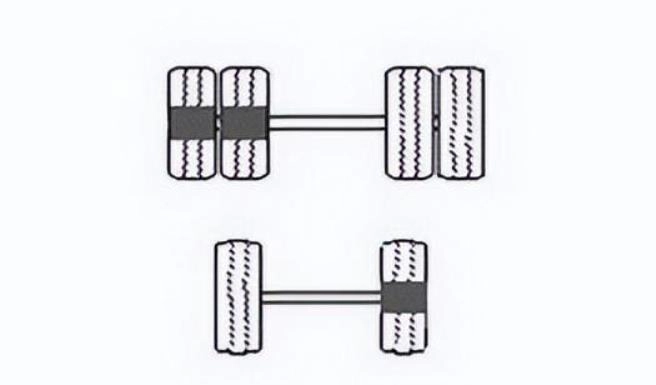

According to the practical application of different categories, trailer tires are also designed with different patterns, what are the differences between these patterns? How should the owners choose? The following DARO trailer axle introduces several of the most classic tire patterns:

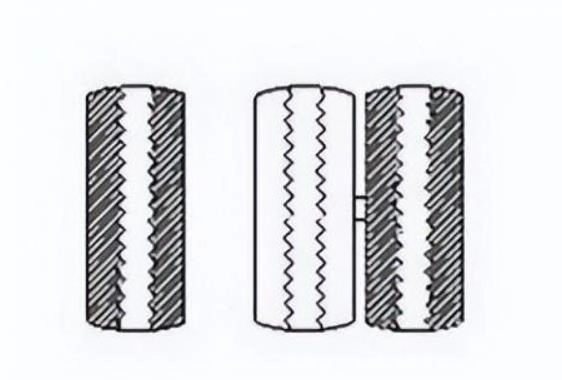

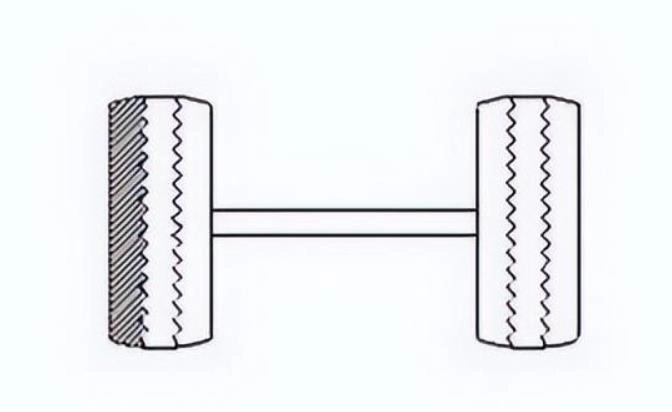

1. Horizontal pattern

It is generally suitable for medium and heavy trailers with hard road surface or large traction. This kind of tread is transverse continuous and longitudinal disconnected, so the transverse stiffness is greater, the longitudinal resistance to sliding is stronger and the horizontal resistance is weaker. When the vehicle turns at high speed, it is prone to sideslip. In addition, the rolling resistance of the tire is also greater, which will exacerbate tire wear.

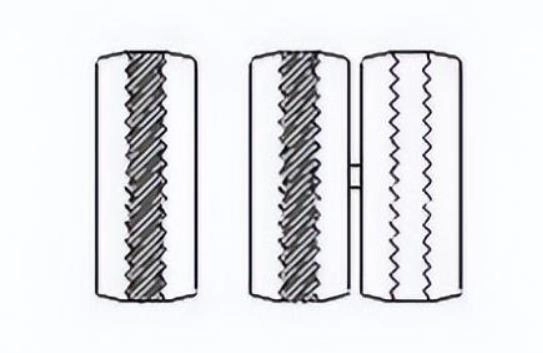

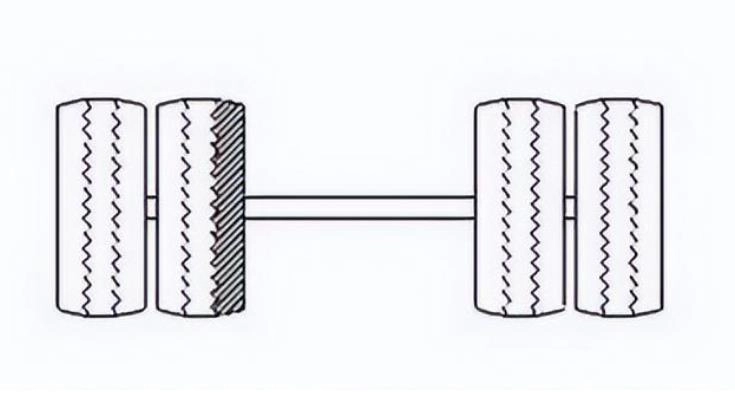

2. Longitudinal pattern

This pattern is more common on passenger cars and light and micro trucks, and is suitable for driving on clean and good hard roads, such as urban roads and highways. This pattern is longitudinal continuous and transverse disconnected, so the degree of skid resistance of the tire is characterized by strong transverse and weak longitudinal, small rolling resistance, good heat dissipation, but it is easy to embed stones and other foreign bodies.

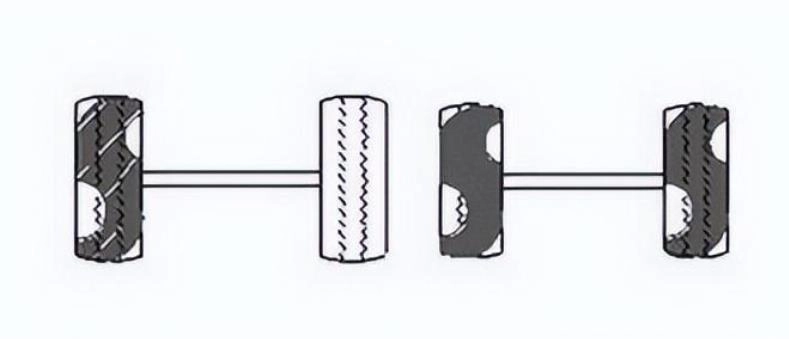

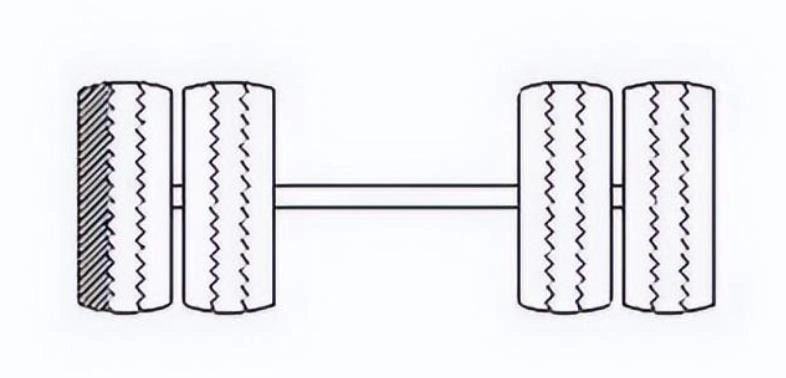

3, crossbar mixed pattern

The tire of this pattern has a wide range of applications and can generally be used for passenger cars or trucks. This tread is between the longitudinal pattern and the horizontal pattern, the zigzagged longitudinal pattern is designed in the middle part, and the horizontal pattern is designed in the shoulder position of the tire, so the longitudinal or horizontal anti-slip ability is better.

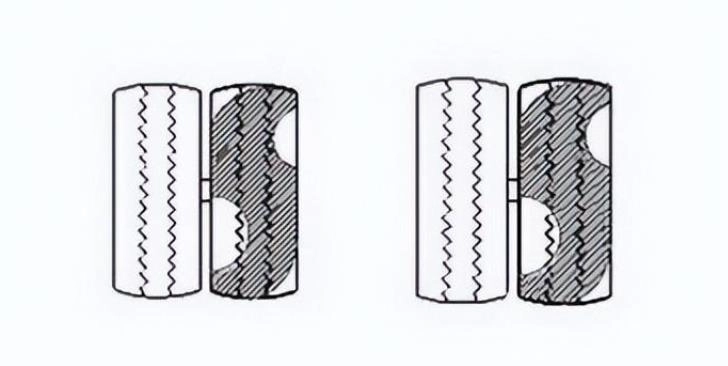

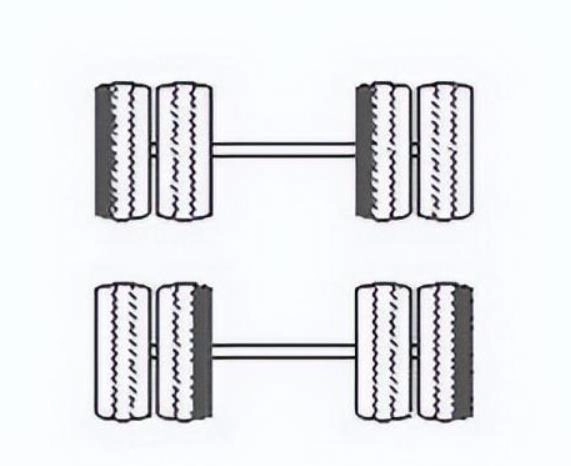

4, independent block pattern

This pattern is generally more suitable for snow or muddy roads, with a very special driving force, braking force and steering stability, generally more used in off-road vehicles.

Back to the beginning of the article, the tire loss rate of the trailer is generally higher than the passenger car, the phenomenon of eating tires is more common, if the owner can identify the common phenomenon of eating tires, some simple maintenance problems can be solved by themselves, even if you still need to go to the maintenance point, you can also know yourself and your enemy, to prevent being cheated by bad businesses.

Next, DARO trailer axle will send you 18 common tire eating problems and solutions for your reference.

1, a single tire tread on both sides of the shoulder abnormal wear.

Solution: Check whether the tire pressure is too low and whether there is a problem with the tire quality.

2, a single tire tread center abnormal wear.

Solution: Check whether the tire pressure is too high, or whether there is a problem with the tire quality.

3. Steering axle tread shows "S" type wear.

Solution: Check whether there are problems with the front bundle, steel ring, steering ball head and direction machine fixing.

4, rear axle tire surface shows "S" type wear.

Solution: Check whether the steel ring, wheel hub, shaft bolt is loose.

5, the tire tread fixed an abnormal wear.

Solution: Check whether the brake hub is out of round.

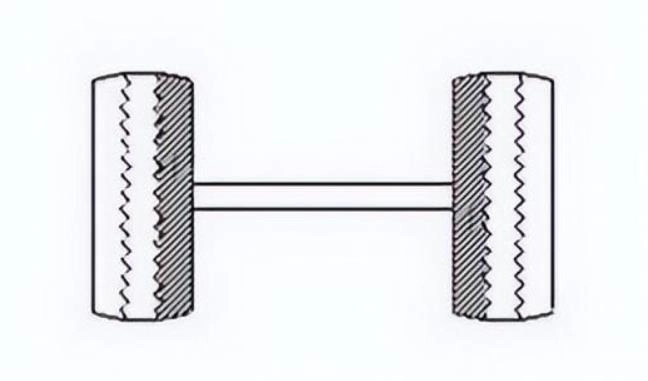

6, the two tires on the coaxial, the inner edge of abnormal wear.

Solution: Check whether there are problems with the front bundle and steering knuckle kingpins.

7, the two tires on the coaxial, abnormal wear outside.

Solution: Check whether there is a problem with the front beam size.

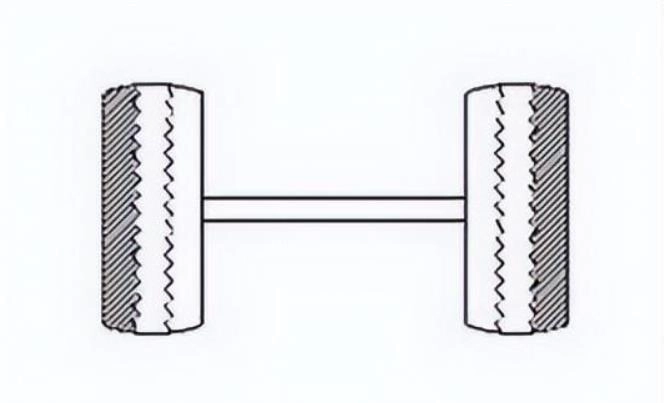

8. Abnormal wear on the inside side of the tire on the steering axle.

Solution: Check the steering knuckle kingpin.

9. Abnormal wear outside the single side tire of the steering axle.

Solution: Check whether the front axle and steering knuckle kingpin are deformed.

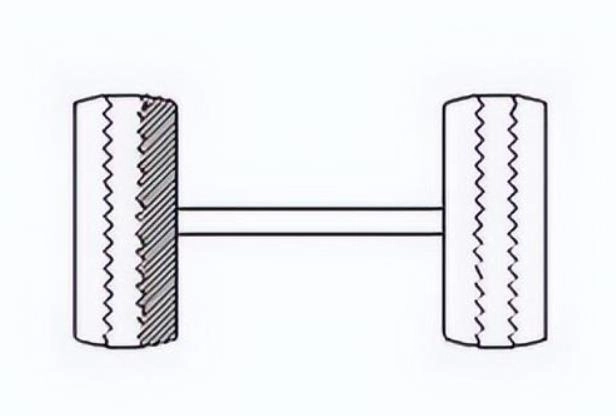

10. The inside edge of the rear axle tire is abnormally worn.

Solution: Check whether the hub bearing clearance is too large, whether the hub and bearing housing are loose, and whether the shaft guide is deformed and bent upward.

11, the rear axle side of the vehicle tire outside abnormal wear.

Solution: Check whether the steel plate center screw, steel plate pin bushing and steel plate lifting lug are loose.

12, the rear axle tire outside, one side of the tire inside abnormal wear.

Solution: Check whether the steel plate center screw, steel plate pin bushing and steel plate lifting lug are loose.

13. The inside of a single tire on the steering axle of a two-front axle vehicle is abnormally worn.

Solution: Check whether the tire axle steering knuckle kingpin, hub bearing and ball head are loose and whether the front bundle is too large.

14. The outside of a single tire on the steering axle of a two-front axle vehicle is abnormally worn.

Solution: Check whether the front bundle of the tire bridge is too small, and whether the steering knuckle kingpin and axle are deformed.

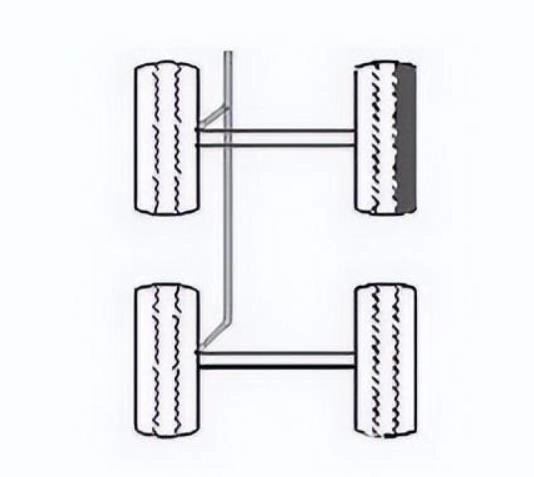

15. The inside and outside of the tire on the steering axle of the two-front axle vehicle are abnormally worn.

Solution: Check the steering synchronization and the axle suspension positioning.

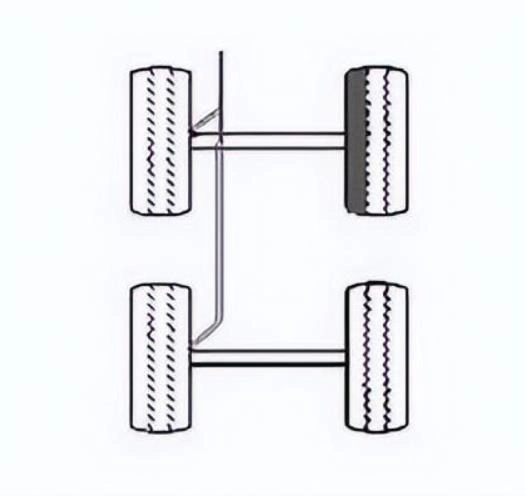

16, two front axle vehicle steering axle coaxial tire on one side of the inside, one side of the outside abnormal wear.

Solution: Check the steering synchronization and the axle suspension positioning.

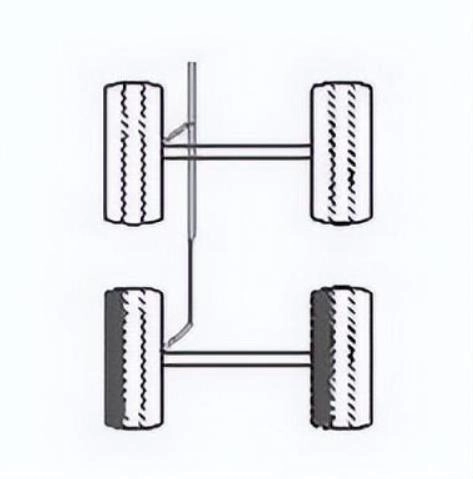

17. The tire outside of the two axles of the double front axle vehicle is abnormally worn.

Solution: Check the steering knuckle kingpin.

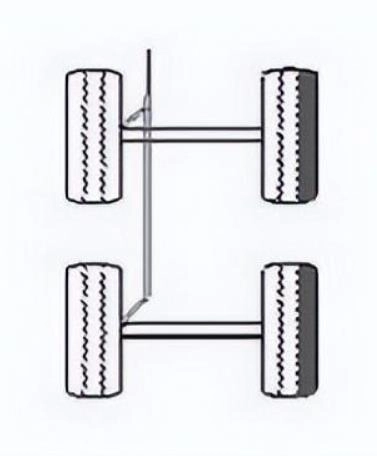

18. The inside edges of the tires on the two axles of the double-front axle vehicles are abnormally worn.

Solution: Check whether the front axle and steering knuckle kingpin are deformed.

Through the above content, we can find that the influence of wheel hub, bearing, steel ring, shaft head bolt, etc. on the abnormal wear of tires is still relatively large, so it is necessary to do a good job of regular maintenance and maintenance work, which can save the owner a lot of trouble in use.

In addition, the selection of reliable quality of the axle assembly is also very critical, only raw materials and processes are strictly up to standard, in order to make the axle in the complex transportation environment always maintain stable and good performance. DARO trailer axle is a product specially tailored for the trailer, the raw material selection is high-strength alloy seamless steel pipe, the use of "one-piece" heat treatment molding technology to create, strength toughness and other fully up to standard, such as hub, bearings and other parts are selected for the trailer special high quality products, to ensure accuracy while improving strength and stability.