Semi trailer can be modified "brake King"?

"Brake king" is a trailer circle almost everyone knows the existence, many owners, especially often run mountain road owners, basically used, the original intention is to make the brake more reliable, to ensure the safety of downhill.

The name "brake king" seems to have a little unclear meaning, even if you have not seen the name, a feeling is very strong. In actual use, many owners reflect that after the installation of the "brake king", the feeling of braking is really good, a little bit on the foot, braking force on.

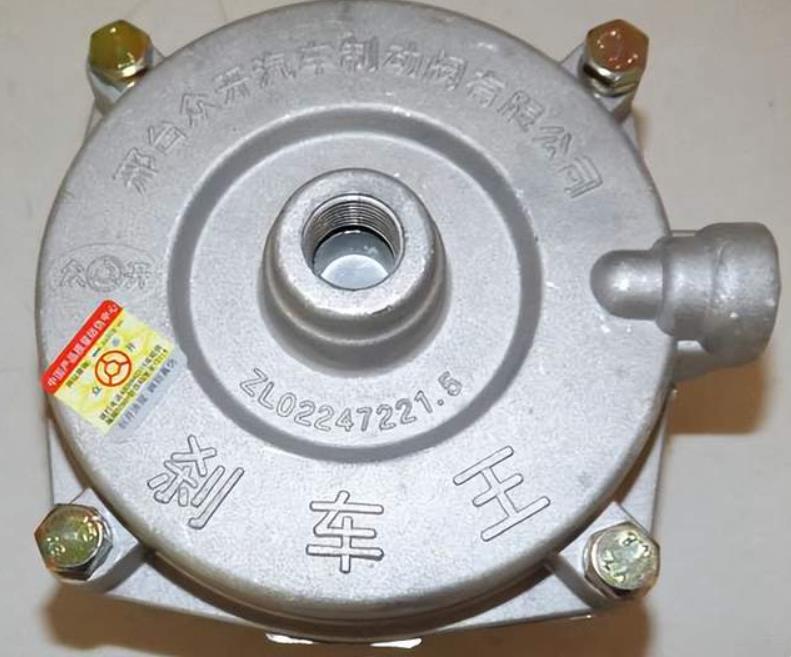

In design, the Brake King is more similar to a pump valve:

Its working principle is to increase the overgas of the brake pump or relay valve, and shorten the response time by increasing the overgas, that is, to destroy the linear increase of the original braking pressure, directly ignore the section with small braking pressure, and advance the section with large overgas, so that the owner can feel the braking performance is good.

But correspondingly, when the car is empty, because the "brake king" filters out the small air pressure that section, the brake is easy to produce a little bit of the feeling of holding. In order to avoid this phenomenon, the once popular "empty weight valve" has appeared. By reducing the air volume, the feeling on the feet of the owner becomes softer, and the braking will not be so fierce when the car is empty. "Soft brake king" is also the truth, but in the valve body set into a throttle valve, so light braking is soft, not easy to hold the empty car.

The key question is: is this brake king reliable?

In fact, through the working principle of the "brake king", it can be seen that the braking effect brought by the "brake king" is achieved by controlling the air volume. Whether the braking force is strong or soft, the principle has not changed.

As we all know, the braking performance of the vehicle is a system, we must pay attention to coordination, especially the trailer, we must cooperate with the main hanging, in order to ensure the braking effect. After the replacement of the "brake king", although the owner subjective feeling brake force comes fast, but it is easy to affect the coordination of the vehicle, leading to the imbalance of the main hanging.

The most obvious is that the abnormal wear rate of vehicle tires has increased; Secondly, the early damage of brake parts such as brake drum and friction plate increased and had to be replaced; In addition, after the modification of the "brake king", the linear growth of the vehicle braking force almost disappeared, popular point is to step on that is to hold, heavy step but no braking force phenomenon; Because the "brake king" increases the air volume, easy to let the brake pressure drop rapidly, for some slow inflation of the vehicle, it may lead to its downhill pressure is insufficient; At the same time, the braking distance of the vehicle is not shortened, but lengthened. These are very dangerous and troublesome things.

Vehicle braking system is the need for frequent maintenance and maintenance, must not be modified "brake king" as the braking force problem after the first choice, although the installation after the surface is indeed stronger braking force, but the braking system problems still exist. For example, once an owner often transported sand and stone, found that the brake is not good to use, installed the "brake king", but still feel bad, the repair of the car only found that the gap between the brake CAM axle bushing and camshaft becomes larger, in fact, as long as the adjustment can be.

Compared with "brake King", ABS reliability is a little better. ABS scientific name "anti-lock braking system", its role is in the vehicle braking, automatic control of brake braking force, so that the wheel is not locked, in the state of rolling edge sliding, to ensure the maximum adhesion of the wheel and the road surface, especially in some slippery road and emergency, to ensure the vehicle's operation.

When the vehicle can brake normally, the wheel does not appear to lock, ABS system is not working, only when the wheel locked phenomenon will play a role, so it is also known as "passive safety device".

Vehicles equipped with ABS devices can prevent wheel locking in the case of emergency braking, maintain steering wheel maneuverability, ensure a higher degree of safety, and save tires compared with locking towing.

But for trailer axles on the market at present, disc axles compared to drum axles, more can help ABS device play the maximum effect. Take DARO disc axle as an example, its brake sensitive, the owner steps on the brake, can immediately drive the brake pad for friction braking, the response is much faster than the drum axle, at the same time, the braking force input is stable, with ABS device, can make the vehicle in the shortest braking distance to stop smoothly.

More than that, DARO disc trailer axles are manufactured by DARO Group using "one-piece" heat treatment technology, which is superior to "three-piece" welded axles in heavy-duty performance. After more than a dozen production processes such as hot spinning rolling, cold pushing square, medium frequency quenching, heat preservation and tempering, CNC machine tool treatment, it strictly conforms to industry standards and has millions of fatigue tests to fully ensure product performance. Owners use more worry, more at ease.