Is the semi-trailer airbag bridge durable?

Lightweight is a major trend in the development of freight vehicles. Judging from the upgrading of vehicles in recent years, various parts that can reduce the weight of vehicles are used more and more frequently, and the airbag axle is one of them. With the promotion of relevant regulations and the blessing of its own advantages, the airbag axle has gradually stepped out of the application limitations of passenger cars, passenger cars, and small cars, and has begun to march into freight trailers.

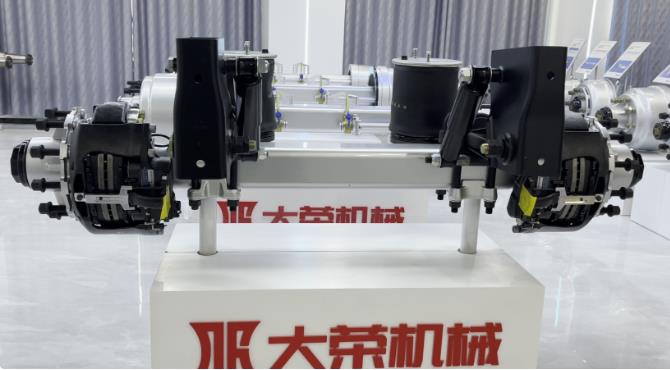

However, car owners who are used to leaf springs will inevitably murmur in their hearts: Compared with leaf springs, this airbag is light and light, how much load can it bear? Will it break easily? Today, I will discuss with you the DARO trailer axle.

Objectively speaking, the airbag axle can get policy support, and it is only one of the reasons that it is in line with the lightweight trend. In addition, the airbag axle can also realize the lifting of a single axle or the entire vehicle. On the one hand, the single axle can be lifted when the vehicle is empty, reducing tire wear and saving fuel; The lower height of the vehicle is more conducive to operation.

In addition, the elastic coefficient of the airbag can be automatically adjusted to match the driving speed of the vehicle, improve the stability of the vehicle body and driving comfort, ensure a constant height of the cargo compartment, fully protect the cargo and reduce the cargo damage rate on poor road conditions . This is also the reason why many green pass car owners choose airbag axles.

Some people say that there are many advantages of installing airbag axles on trucks, but there are almost no disadvantages except high maintenance costs. To be honest, this statement is not very objective. Everything has advantages and disadvantages, but it is just viewed from different angles.

The disadvantages of the airbag axle, one is the high purchase cost, which is not a little bit more expensive than the traditional leaf spring; the second is the high maintenance cost mentioned just now, after all, the structure is relatively complicated, which is also understandable; It is the bearing capacity. The airbag axle is very sensitive to the tonnage of the cargo. It is no problem to meet the needs of the vehicle’s standard load transportation. However, once the overload occurs, especially if the overload reaches more than 10%, it will accelerate the damage of the airbag and greatly affect the service life of the airbag. , Once the airbag is broken, the cost of replacement is not cheap.

Under normal circumstances, the service life of a set of airbag axles is about 3-5 years. Basically, it needs to be replaced when it reaches this range. If the usage is particularly good, it can be used for about 5 years. The service life will also be discounted.

Whether the airbag axle is durable or not depends mainly on the following points:

1. Whether the working conditions are suitable. The airbag axle is suitable for the transportation of green goods, flowers, electronic instruments, dangerous chemicals, fragile goods and other goods. It can protect the goods and improve the safety of transportation. It will be too high. If the airbag axle is used, the vehicle's own weight can be reduced to a certain extent, and there will be more loading space.

However, if the car owner usually transports heavy goods, such as building materials, sand, concrete, wood, coal, etc., it is not suitable to use the airbag axle. Even if it is barely used, the frequency of maintenance and replacement may be very high.

2. Daily use habits. Do you usually run more on highways, national highways, provincial highways, or downroads or mountain roads? Is there any overloading, overrunning or overspeeding? Do you usually pay attention to checking and adjusting the height of the airbag? Do you often expose the airbag axle to high temperature, sand, gravel and other environments? Did you pay attention to check the air bag leakage? Is there grease on the airbag axle rubber...? These are closely related to the service life of the airbag axle.

3. Manufacturing process. The quality of the airbag axle also directly affects the length of its service life, whether it is material selection, design, processing or quality inspection. Car owners must choose airbag axles produced by regular brands, such as DARO airbag axles, which entered the market relatively early, product performance has been fully tested by the market, and users have a good reputation. Such products can be used with relative peace of mind.

In addition, there are American and European airbag axles. The American airbag axle adopts the "I-beam" design, which is generally lighter in weight and tends to be lighter; the European airbag axle uses a leaf spring guide arm, which has relatively higher load-bearing capacity. The adaptability to poor road conditions is also stronger. Owners can choose according to their actual working conditions.