Plate spring suspension more reed or less reed which is better?

Suspension is a connection device between the axle and the frame, which is used to transmit force and torque, reduce the impact of the road surface on the body, reduce the body vibration caused by the road surface fluctuation, and ensure the smooth running of the vehicle.

At present, the common suspensions in the commercial vehicle market are mainly leaf spring suspension and air suspension. Although the call for air suspension has become more and more popular in recent years, it is still difficult to shake the market application rate of 80% of leaf spring suspension. This is mainly because the air suspension structure is complex, the purchase and maintenance cost is high, the load-bearing capacity is poor, and it is not suitable for heavy cargo transportation, so its main application areas are still in the transport of light trucks or dangerous chemicals, flowers, vegetables and fruits and other transport conditions.

Although the spring suspension is not as good as the air suspension in terms of shock absorption performance and self-weight, it has simple structure, low cost and maintenance cost, strong rigidity and high load-bearing force.

Moreover, the leaf spring has a guiding function, can transmit the force and torque in all directions, and the reed can also show linear or non-linear elastic characteristics according to a certain combination of the spring, so it is still widely active in medium or heavy transport vehicles.

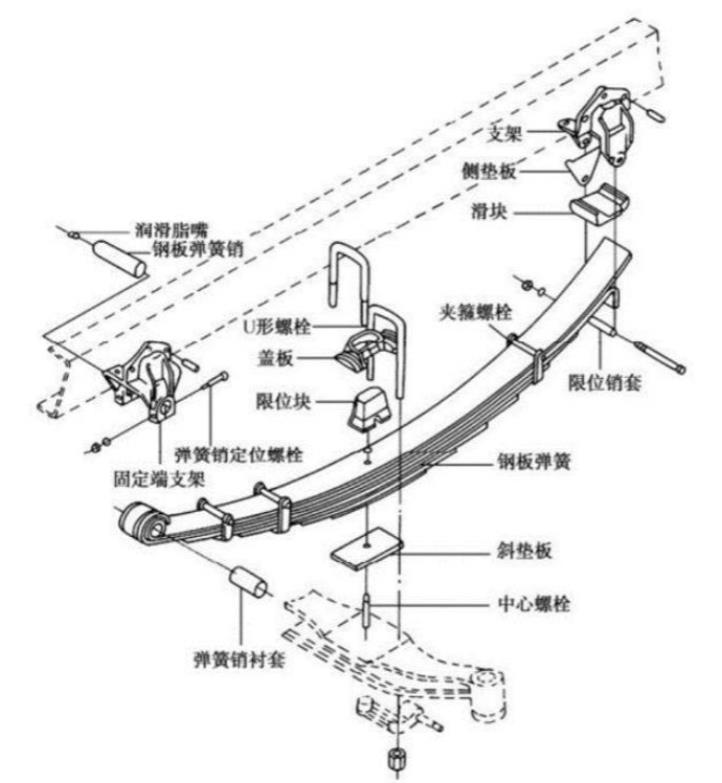

· Plate spring suspension structure:

· Working principle of plate spring suspension:

When the vehicle is driving on the uneven road condition, the wheel bump drives the trailer axle to jump, and the leaf spring and the lower end of the shock absorber move up at the same time. The length of the leaf spring will increase during the upward movement, which is coordinated by the extension of the lifting lug; When the upper end of the shock absorber is fixed and the lower end is moved up, it is equivalent to being in a compressed state, damping is increased and vibration is attenuated. When the runout on the trailer axle exceeds the distance between the buffer block and the limit block, the buffer block and the limit block contact and compression occurs.

· Classification of common leaf spring suspension:

1. Multi-leaf spring suspension:

Commonly seen in heavy-duty vehicles, it is composed of multiple reeds of varying lengths and consistent widths, generally more than 5 pieces. The length of the reed becomes longer from the bottom to the top, and the lowest reed is the shortest, thus forming an inverted triangle, making full use of the force principle of the triangle. In addition, the number of reeds is closely related to the load-bearing capacity, the more the number of reeds, the higher the thickness, the stronger the rigidity of the reed, the bearing force will increase, of course, its own weight can not be underestimated.

Although the multi-leaf spring suspension has a large number of pieces, it has a simple structure and low maintenance cost, because it is rare for the multi-leaf spring to be completely destroyed in use, and it is often only necessary to replace the damaged reed separately. However, when multi-blade springs are used for a long time, they will produce abnormal noise due to mutual friction, and the rigidity will affect the form balance of the vehicle after weakening.

2, less spring suspension:

Less spring is composed of thin reed at both ends, thick in the middle, equal width and equal length, so the cross-sectional area of the steel plate with less spring changes more, the rolling process is more complex, and the price will be more expensive than the ordinary steel plate with more spring.

Compared with multi-blade springs, the load-bearing capacity of less blade springs is weakened to a certain extent, but at the same time, the self-weight will also be reduced. According to relevant data, under the same bearing capacity, less blade springs can reduce the weight of about 30%-40% than multi-blade springs.

In addition to reducing the body weight of the vehicle, the noise generated by the friction of less spring is also smaller, and the driving comfort of the vehicle has also been improved to a certain extent. Under the environment of standardized transportation, less spring has become the most common suspension structure.

However, the maintenance cost of less spring is relatively high, once the reed is broken, the other reed is often prone to damage due to the uneven force, so the replacement is generally a full set of replacement.

The above two spring suspensions are the most common in the market, in addition, there are also some improved suspensions based on more and less reed:

3. Main and auxiliary composite suspension:

It is composed of the main and secondary springs. When the load of the vehicle is small, only the main springs play a role. With the increase of the load, the secondary springs and the main springs play a role together, and their elastic characteristics show nonlinear changes.

4, graded stiffness leaf spring:

The secondary spring is placed under the main spring, the main spring and the secondary spring form an integrated structure, and its elastic characteristics show nonlinear changes.

· Precautions in the use of plate spring suspension:

Some owners believe that the spring suspension is composed of a stack of steel plates, should not be too fragile, so in use will not pay attention to the protection of the suspension, this understanding is actually wrong, the spring suspension also needs to do daily maintenance and repair.

1, develop good driving habits, when the vehicle heavy load through the rough road or speed bumps, to slow down the speed, while trying to avoid sharp turns, otherwise easy to increase the weight on one side, not only cause damage to the reed, and even hurt the steel ring and other components, affecting the stability of the vehicle.

2, spring suspension in the use of the process, the wear coefficient is very large, especially in the case of poor road conditions, more prone to reed fracture. When replacing the reed, especially the multi-spring suspension, even if the other old reed is not damaged, it is necessary to adjust its position. Otherwise, the rigid strength of the new reed and the old reed is inconsistent, and a gap will be left between the two after installation, which will aggravate the wear of the new reed and cause excessive force on a single piece.

3, the daily need to pay more attention to the maintenance of the spring, the lifting ear butter is indispensable, the upper limit position of the auxiliary steel also needs to play more butter, lubrication while reducing abnormal noise, so that the spring more easily cope with the increased friction coefficient, avoid the phenomenon of surface strain, reduce the possibility of reed fracture.

4, the usual maintenance must also pay attention to the fixing of the leaf spring riding bolt, the fastness of the center bolt, to avoid the loosening of the riding screw, resulting in the failure of the whole set of plate springs, and even to the driving threat. The higher the weight of the general vehicle, the more frequent the inspection.

5, the choice of the number of plate springs depends on the load of the vehicle, when the vehicle is often in a heavy load or heavy state, it is necessary to consider improving the plate spring to the original car, so as to enhance the mechanical performance of the plate spring and improve the service life.

6, try to choose the regular brand production of plate springs, after all, the suspension is directly related to the load bearing of the vehicle, especially heavy-duty vehicles, in the choice of products is still cautious.

I hope that all owners can use the leaf spring suspension according to the regulations, regular inspection, maintenance and maintenance, after all, the vehicle "three points of repair and seven points of maintenance", keep the vehicle in order to obtain more long-term benefits.