Old driver tips: How to unload a rollover semi trailer?

Dump truck is a kind of engineering vehicle. Its principle is to drive the hydraulic mechanism through the engine, drive the lifting mechanism to complete the incline to achieve the purpose of unloading, reset after the completion of unloading, greatly save the unloading time and labor, shorten the transportation cycle, improve the production efficiency. It is widely used in mining, water conservancy construction, road construction and other fields.

From the lifting way of the dump truck, it can be divided into rear and cartwheel type. Today, we focus on the cartwheel type semi-trailer.

In fact, most of the previous dump trucks are back flip, but the height of the back flip semi-trailer for lifting rod is relatively high, usually the height of the rod is affected by the length of the carriage, the longer the length of the cargo box needs the longer the length of the rod. However, the design of the ejector rod is to climb the design, the more to the top of the finer, so it is very bad for the lateral stability of the lift.

In this case, the rollover semi trailer came out, and its biggest advantage is that the height of the lifting rod is smaller, even less than half the height of the back rollover rod. The top rod of the rollover semi-trailer is generally distributed evenly at the bottom of the cargo box in a word shape, with large lifting force and improved lateral stability. Especially for the long semi trailer, rollover dump is more suitable.

In addition, the rollover dump truck is generally equipped with a shift bar in the design, which can help reduce rollover to a certain extent, but it can not be completely avoided, and it also needs to be strictly regulated.

Of course, there are advantages will have disadvantages, the disadvantages of the flip semi trailer is also more obvious, mainly to the unloading site requirements are higher, and easy to bury tires when unloading, cargo unloading is not clean. So, are there any tips for unloading a rollover semi?

1. The unloading site shall be flat. This is the owner should first pay attention to the problem, must choose the ground level place to unload, especially the left and right sides can not exist slope. If the center of gravity deviation occurs after the dump truck cargo box rises, it is very easy to cause the rollover phenomenon.

2. The ground for unloading should be firm. Dump truck is generally relatively large weight, if the ground is soft, it is easy to lead to the wheel sag, body shaking or vehicle rollover.

3. The guardrail of the unloading part is converted into a baffle plate. This is also a method provided by the owner to prevent the buried tire, the guardrail next to the tire is converted into a baffle, pay attention to the height of the ground, so that it is not easy to bury the tire when unloading.

4. The ejector rod should not be raised all at once. It is suggested that the owner pay more attention to observe in the unloading process, the top rod rises a section to observe the vehicle, if there is no offset or buried tire, then rise the next section.

5. Pay more attention to observation during unloading. During the unloading process, the owner must observe the changes of the carriage from the rear window. If the tire sinks and the body tilting, the loading and unloading should be stopped immediately. It is best to arrange another person outside the car to assist in the observation.

Some owners said that when the rollover semi trailer unloaded, it could keep the front and the carriage at a certain Angle, generally no more than 45°, to maintain the balance of the body.

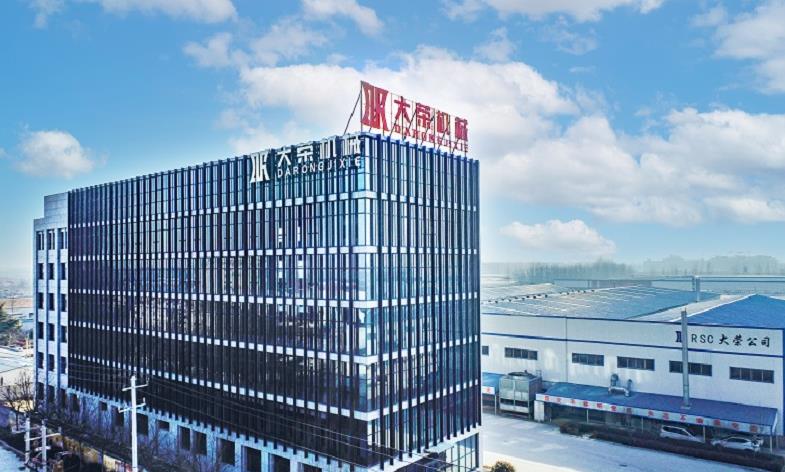

It is worth noting that, because of the lifting way of rollover dump truck, the beam and chassis are easy to be stressed unevenly when unloading, so the requirements for the chassis are higher, especially the trailer axle, which is not only the key component of the chassis bearing, but also related to the braking, driving and other performance of the vehicle, must be 100% reliable. DARO Heavy Industry Group is Liangshan's first mass production of integrated trailer axle enterprise, has accumulated 20 years of experience, with 32000㎡ standard chemical plant, from the next to the assembly of more than a dozen production processes, trailer axle strength, toughness, elongation, fatigue resistance and other leading performance, millions of fatigue tests, for owners to provide higher security at the same time, Improve vehicle operation efficiency.