Mother and son trailer cost reduction efficiency is reliable?

In our country's road transportation, the types of semi-trailers can be said to be diverse, then, have you heard of or seen the semi-trailer? Strictly speaking, the semi-trailer is not a model, but refers to a mode of vehicle operation, the specific principle is that the two vehicles only transport one-way goods, empty car to return, a car carrying another car back.

In fact, semi-trailers have been widely available in the early years. A decade or two ago, when the network was not developed, owners could only obtain distribution information through offline means, and it was very difficult to find the right goods in unfamiliar areas, so many times the vehicle return trip could only choose empty. In order to minimize operating costs, owners thought of this "car back car" way, at that time in some areas also appeared to serve the "car back car" business.

In the past few years, in the coal transportation industry, the seed semi-trailer has risen again, especially in long-distance coal transportation, after the semi-trailer is charged according to the axle, the cost of empty car return has increased, and many teams have begun to choose the model of mother and child to reduce the comprehensive cost.

At this time, the child semi trailer compared with the past to do a new design, in addition to the mother and the child of the top and height of the car to do more reasonable planning, other aspects have also been improved, such as the mother to choose a high-top two-bedroom cab, can facilitate the driver of the car rest, the child is to choose a flat top lightweight cab, in order to cope with the height limit of the road and reduce fuel consumption.

As for the operational advantages of the semi-trailer, it is also relatively obvious:

1, save the return tolls, fuel costs and related expenses, according to the relevant survey, this "car back car" way in the case of 1500km, fuel costs can save about 800 yuan, tolls can save about 1400 yuan, in addition, such as parking fees, tire damage and other costs can also be reduced.

2, reduce labor costs, improve operational efficiency, "car back car" under the general selection of three drivers, through the cycle system attendance, compared with the past car hiring two drivers can reduce part of the labor costs, but also can ensure the driver's safe sleep, improve operational efficiency.

In this way, it seems that the semi-trailer does have a certain cost reduction and efficiency effect, but is this "car back car" method worth advocating? Let's first analyze a few questions:

1, not suitable for all logistics scenarios. The trailer is suitable for special markets where the journey is full and the return journey is empty, such as coal transportation with fixed lines and pairs, or remote lines with large inflows and small outflows. For those retail owners, it seems that it is not so easy to find two semi-trailers with the same source and the same line;

2. Transportation safety issues. Especially after the combination of the child and the mother car, the child itself belongs to an indivisible large goods, and its contact area with the mother car is relatively limited, the friction is too small, if the mother car is designed with a special fixed tool, otherwise, once in the transportation process encountered sudden braking, the child is easy to produce displacement because of inertia, affecting driving safety.

3. Operation compliance. In fact, the semi-trailer is also a "loophole" product, in accordance with the requirements of regulations, the transport sub-vehicle must use a special flat truck, there is no clear regulations to allow or stipulate that the semi-trailer can be on the road, "car back car" way or there will be ultra-high, overweight and other problems.

Therefore, this "car back car" way is only a helpless move taken by owners under the condition of freight depression, and it is not worth promoting, but there are special market exceptions. For example, professional logistics companies, in the fixed transport lines, in strict accordance with the legal size requirements of the design of a special large and small semi-trailer, in pairs, the return of the car back to the car. For example, new car transportation, the mother car is a low flat semi-trailer, its chassis is much lower than the ordinary semi-trailer, and it can generally transport the traction locomotive or small passenger car to achieve "car back car".

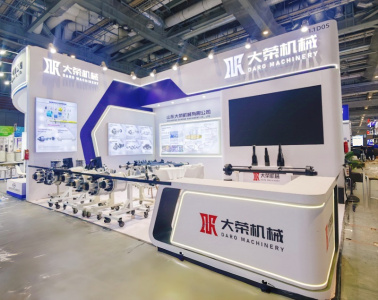

It is worth noting that the "car back car" method has higher requirements for the stability of the main car, the center of gravity of the vehicle, and the body weight of the vehicle, and the selection of the trailer axle and suspension naturally gets twice the result with half the effort. DARO Group has been deeply engaged in the trailer axle industry for more than 20 years, and its products are rich and diverse, such as disc trailer axle, drum trailer axle, low flat trailer axle, concave trailer axle, three-line six-axle, air suspension, etc. The process, technology, experience, and strength are trustworthy, and can meet the diversified needs of users.