Is modular trailer production a trend or a joke?

Trailer production modularity, in simple terms, is to divide a car into several large modules, each independently designed and produced, and then assembled together.

Modular design is not a new idea. The "King of the road" reputation of Scania, in addition to large displacement engines, is also due to its modular design and production to a certain extent trailer axle.

In China, as early as 1998, the concept was proposed by the industry, and the main parameters and production processes were also given for the main modules such as traction pin, frame, suspension, wheels, brake system and bar plate. But until now, most trailer factories have not been able to apply the modular method.

On the one hand, the technical level of most trailer plants is not uniform, the lack of protection in production accuracy and product consistency, if you want to solve this problem, you need to invest a lot of money, production costs compared to the current will rise sharply, which is the trailer plant is not willing to see;

Secondly, the use conditions of domestic trailers are more complex, difficult to unify, so the demand for customization is strong, and the configuration is also diverse, so that individual parts are difficult to achieve mass production, which is also one of the reasons why modular production cannot be implemented.

However, some professionals pointed out that with the gradual standardization of the trailer market, production technology is also generally improving, some head car companies have already had the conditions for modular production, I believe that in the near future, the domestic trailer design and production of modular.

What are the advantages of modular design and production trailer axle?

1. Higher production efficiency and lower production cost

Under the traditional production mode, the quality of products mainly depends on the technical level of workers. After the adoption of modular production, more production processes will be performed by robots, and product quality will be more dependent on design and management, which can reduce labor costs to a certain extent. At the same time, the increase in automation has led to an increase in output, and the cost allocated to each component will be lower, which is more conducive to the cost reduction and efficiency of enterprises.

2. More efficient cross-regional distribution of new cars

All along, trailer companies have smaller profits and higher long-distance sales and transportation costs, so it is difficult for even large companies to sell cars to distant areas. Modular production is different, because the modules are separated from each other, the module can be directly transported to the point of sale and then assembled, compared with the traditional "back" transport or to the factory to pick up the car, the efficiency is improved a lot, the cost is lower.

3, higher after-sales efficiency, more convenient replacement parts

The modular design is very conducive to after-sales maintenance, especially when the trailer module components have problems and the traditional repair can not help, the module can be replaced directly, which can improve the maintenance efficiency and ensure the performance of the vehicle to a greater extent.

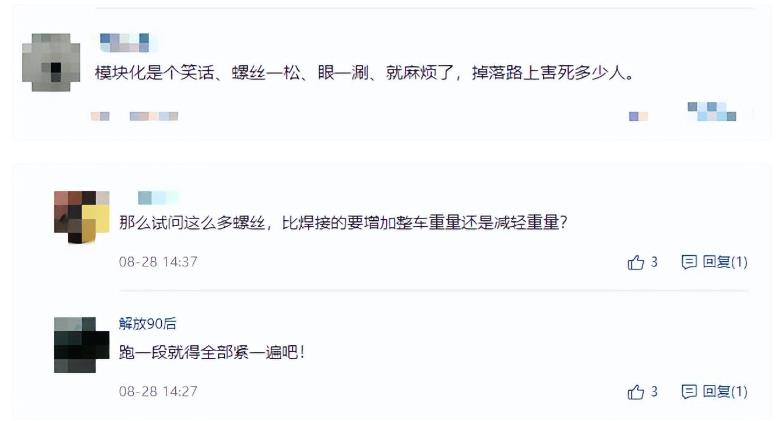

In principle, modular design and production can shorten the product delivery cycle, improve the standardization of the trailer market, and product quality can also be improved to a certain extent, which is a good thing for owners trailer axle. However, the owners of the modular production has always been skeptical, and even think that modular production is a joke.

In fact, it is not difficult to see that the owners question the trend of modularity, but the actual performance of the product under the trend of modularity, after all, the vehicle is to be put into the market after production, performance is the most critical factor.

Modular design and production of trailers may be a general trend, but at present, there are still many problems to be solved. Just like the modular connection problem mentioned by the owners, can it ensure that it is strong and not loose? Do you need frequent daily check-ups? Are problems that need to be solved. Only when these doubts are eliminated can modularity be popularized on a large scale, otherwise, I am afraid it can only be on paper.