Load-bearing capacity of broken axle?

The axle is an essential part of the vehicle, which plays the role of bearing the load of the vehicle, maintaining the vehicle driving and providing the vehicle braking. It is generally connected with the frame or body through the suspension, and the two ends are used to install the wheel. According to the different models and the use of different needs, the axle can also be divided into many kinds, if the single look at the structure form, it can be divided into integral and broken two kinds.

The integral axle is easier to understand. Most trailer axles we see at ordinary times belong to the integral axle. The wheels at both ends are connected and fixed together by a shaft beam in the middle. What is a broken axle?

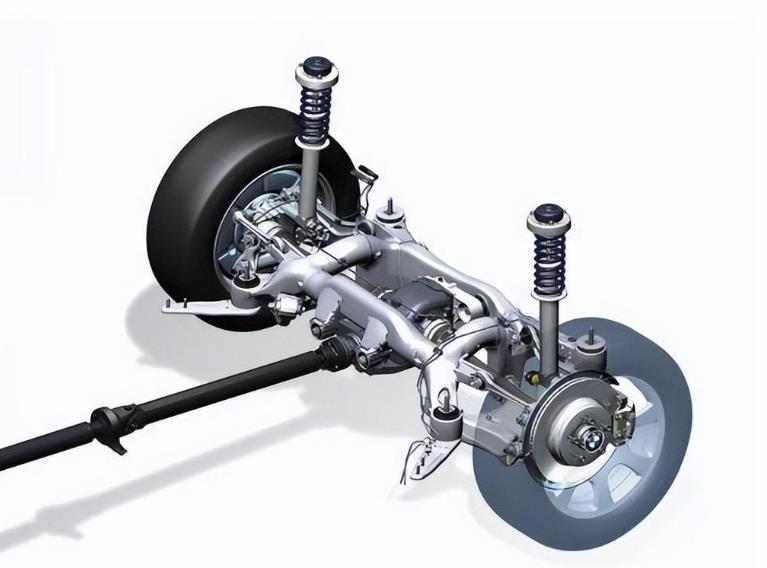

The broken axle is relative to the integral axle. The middle of the wheels at both ends is connected with the joint structure, which is connected to the lower part of the frame through the suspension, so that the relative motion can be realized. Generally speaking, the two wheels of the broken axle can respectively achieve up and down motion and do not affect each other, which is mainly due to its two wheels using independent suspension.

From this point of view, the use of broken axle can effectively improve the body clearance off the ground, reduce the body by bumps and vibrations, improve the comfort of drivers and passengers.

In addition, because there is no shaft beam connection in the middle of the broken axle, the position of the engine can also be reduced or moved forward to a certain extent, so as to reduce the center of gravity of the vehicle and improve the driving stability.

Therefore, the broken axle is more suitable for complex, harsh, high requirements for vehicle traffic conditions, such as military vehicles, off-road vehicles, etc.

What about the load-bearing capacity of a broken axle? Due to the joint structure between the two wheels of the broken axle, its load-bearing performance can not be compared with the hollow or solid shaft beam of the integral axle to a certain extent. Therefore, in many freight vehicles, such as the more widely used semi-trailer, the use of integral axle.

Compared with the split axles, the monolithic axles are simpler in design and can provide more load and torque. In addition, because its half shaft and other parts are in the sealed shaft beam operation, so it is easier to daily maintenance and maintenance, even in the modification aspect than the broken shaft is much simpler.

DARO trailer axle is a professional axle manufacturer in China, which has accumulated 20 years of research and development and production experience. Its disc axle, drum axle, low flat axle, three-line six-axle, concave axle, special axle and other applications are only available. From the perspective of classification, they all belong to the integral support axle. The use of "one-piece" shaft casting technology has greatly improved the bearing performance of the axle. It is specially built for heavy-duty transport vehicles with stable quality and affordable price. It is a typical representative of the trailer axle with high cost performance in China.