Just a piece of iron? A semitrailer saddle is not that simple

With the rapid improvement of China's economic level, the transportation industry has also made great progress, especially the road transportation. The semi-tractor bears 60% of the road transport volume, the demand is increasing, the superiority is becoming more and more obvious, is gradually becoming the main force of transportation, because of its large transport volume, convenient loading and unloading, low transportation cost, so that it has become one of the main trailer axle means of transportation in the transport industry.

The saddle is a key component connecting the tractor and the semi-trailer, plays an important role in transmitting the longitudinal and braking power between the saddle and the trailer, and the saddle also bears the impact of the tractor starting, turning, braking and other forms of movement, its structure directly affects the operation safety of the entire system.

The tractor saddle is a swinging horseshoe-shaped plate of wear-resistant steel. The trailer pressure is applied to this plate, which has a notched semi-circular hole in the center. The hole wall is made of crash-resistant forged steel.

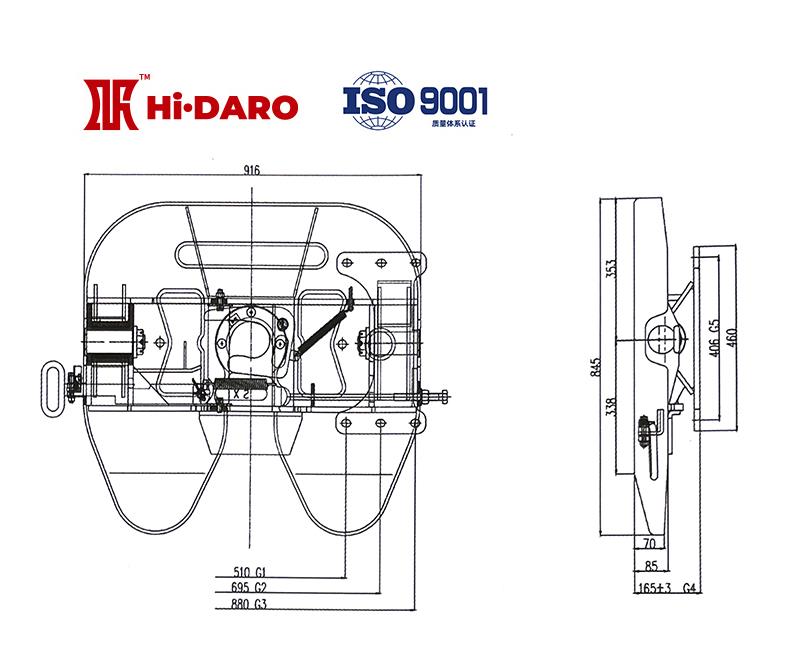

I. Composition of the saddle

1. The saddle body, the main component of the saddle.

It is composed of the shell (also known as the seat cover), the front frame plate, the rear frame plate, the M-shaped frame plate, the inner frame ear, the outer frame ear, the U-shaped plate, and the tail slide cover plate.

2. Bracket, used to hold the saddle.

The two brackets are connected to the vehicle girder by the saddle base plate, thus securing the saddle and providing support.

3. Pull rod, used to control the relative movement of the lock hook and the inclined iron.

The pull rod separates the hook from the saddle by driving the diagonal iron to move laterally. In the normal operation of the semi-trailer, the pull rod is fixed by the locking boss, and then the locking hook and the saddle are realized to ensure the connection trailer axle between the tractor and the semi-trailer.

4. Inclined iron, used to control the separation and locking of the lock hook.

The inclined iron is driven by the pull rod to move laterally, and assists the locking hook to rotate at a certain Angle to realize the locking and separation of the traction pin.

5. The locking hook is used to control the locking and separating of the traction pin.

When the inclined iron is moved to the right position, the U-lock hook will be subjected to the tension generated by the spring and then rotate around the pin seat at a certain Angle to realize the locking and separation of the traction pin, and realize the connection and separation of the two cars.

Second, the saddle working principle

1. Unhang separation:

Loosen the safety and pull the pull rod to the outside manually. The move of the pull rod causes transverse displacement of the inclined iron, while the spring produces tension due to deformation, which drives the lock hook to rotate around the pin seat. At the same time, the opening of the lock hook turns to the outside to achieve the decoupling of the traction pin and complete the separation of the two cars.

2. Connect:

Repeat the above steps to make the opening of the lock hook turn outward-side. When the tractor makes the opening of the lock hook opposite the traction pin, it moves backward until the collision occurs. The lock hook rotates to the starting position under the action of spring rebound, and the tie rod is released and the inclined iron automatically returns to the original position.

Iii. Classification of saddle

According to the size of the traction pin, it is divided into No. 50 and No. 90, that is, it is usually called No. 50 saddle and No. 90 saddle. Trailers used for ordinary road transport are usually enough with 50 saddles, and 90 saddles are used more in construction machinery transport trailers and heavy-duty trailers.

In addition to the corresponding trailer traction pin different, in the same tractor chassis installation, the height is also different, 50 saddle height from the ground is less than 90, of course, after the trailer height is also lower, vehicle stability is better. Previously, most of China's tractors used 90# saddles, but according to the requirements of regulations, the future will be replaced with 50# saddles.

The 90 saddle is more powerful and can tow semi-trailers with a total mass of less than 100 tons, while the 50 saddle can only tow semi-trailers with a total mass of less than 50 tons. Due to more overloaded transportation in the past, the market share of the 90 saddle is higher, and in order to maintain better interchangeability, basically most of the tractors have adopted the 90 saddle.

At present, GB 1589-2016 "Automobile, trailer and automobile train exterior size, axle load and mass limits" stipulates that the total mass of six-axis tractor is less than 49t, and the carrying capacity of 50# traction pin can meet the transportation needs. JT/T 1178.2-2019 "Operating truck Safety Technical conditions Part 2: Towed vehicles and Trailers" clearly stipulates that the tractor should use No. 50 traction seat;

However, from the implementation level, the relevant requirements of 50 saddles are mainly checked when the vehicle is applied for the operating certificate. The saddle and frame of the tractor are bolted, which is not troublesome to replace, although there is a risk of "illegal modification", but it is difficult to be found on the road. At present, most of the traction pins and the frame are connected by welding, if cut and replaced, it will cause damage to the carrying capacity of the trailer. Nowadays, some trailer factories have introduced traction pins or double traction pin trailers with bolt connection.

Four. Saddle maintenance

The life of the saddle depends on whether grease is applied to the trailer axle saddle panel, the traction pin and hook mating surface, the hook, the pin block, and the hoof mouth during the first use. Please use a qualified heavy duty grease, graphite or molybdenum disulfide heavy duty grease is recommended. Its good extreme pressure and wear resistance will ensure that the saddle surface will not produce abnormal wear under normal working conditions.

After the first use of grease, clean the above lubricating parts every 5000km, and re-brush the grease. Before applying grease each time, ensure that the traction pin is free of impurities and burrs, and the horseshoe mouth is free of impurities.