How should trailer tires be selected?

Tire is a very important part of the trailer. As the only part in contact with the ground during the running of the trailer, it supports the body and cushions the impact of the ground. Especially some trailer tire use conditions are more complex, need to meet high-speed, heavy load, rain, snow, sand and other harsh conditions, bear a variety of deformation, load, force and high and low temperature, so the trailer tire must have high bearing performance, traction performance and buffer performance, but also have good wear resistance and low roll resistance and heat generation.

In general, how much do trailer tires cost?

Generally speaking, the price of trailer tires ranges from 1000 yuan to 8000 yuan, which is closely related to the brand and type of tires chosen by the owner. There are also some differences in prices in different regions.

How to choose the trailer tire? It is suggested that the car should take full account of vehicle performance, driving habits, driving routes, climatic conditions, etc. Next, let's briefly talk about the matters for attention in the selection of trailer tires:

1. The trailer should choose harder tires, which can resist tread wear to a certain extent.

2. Steering tires generally choose four longitudinal patterns, which can fully reduce the resistance of the trailer when driving, especially when driving on curves, which can further increase the guiding and anti-sideslip ability.

3. Special tires are still based on four longitudinal patterns, but the shoulder area is different from other wheels, which is generally relatively large and can enhance the ability to resist transverse scratching. The steel wire strap structure inside special tires is also special, with stronger puncture resistance, collision resistance and impact resistance.

4. The driving wheel generally chooses four or five longitudinal stripes with dense horizontal stripes to form block patterns. These patterns can greatly improve the passability of the tire, improve the bearing capacity to a certain extent, and extend the service life of the tire.

5, general purpose tire recommended to choose three longitudinal lines, because its contact with the ground area is larger, the shoulder is wider and thicker, with better anti-wear ability.

6, as far as possible to choose Shun flower tires, that is, longitudinal pattern tires, so as to minimize the resistance of the vehicle driving, reduce fuel consumption to reduce costs, against transverse scraping, reduce the probability of tire sideswipe.

7. In terms of tire type, 12.00R22.5 vacuum tires are generally used for long-distance and good road conditions. 11.00R20 steel wire tire or 12.00R22.5 piece flower series vacuum tire for short distance and poor road condition; Low flat plate, three wire six axle generally used 825-16 vacuum tire or 820-R20 steel wire tire; The skeleton trailer can be selected from the 385 Series large singletons.

8, if most of the road driving, straight hook, wide ditch pattern drainage is good, can also reduce fuel consumption, avoid water skiing phenomenon; If the secondary road driving more, you can choose higher wear resistance of the tire; If there is more mixed road surface, it is recommended to choose mixed pattern, that is, medium flower.

In addition, the selection of the trailer axle is also very important. As we all know, the tire is connected to the hub through the rim, and the hub is an important part of the axle. If the quality of the axle is not up to standard, such as insufficient material strength, false axle parameters, axle alignment/heat treatment and other processes are not up to standard, it will increase the deformation of the axle after leaving the factory, directly lead to the occurrence of tire eating or failure in the use of the trailer, and greatly reduce the service life of the tire.

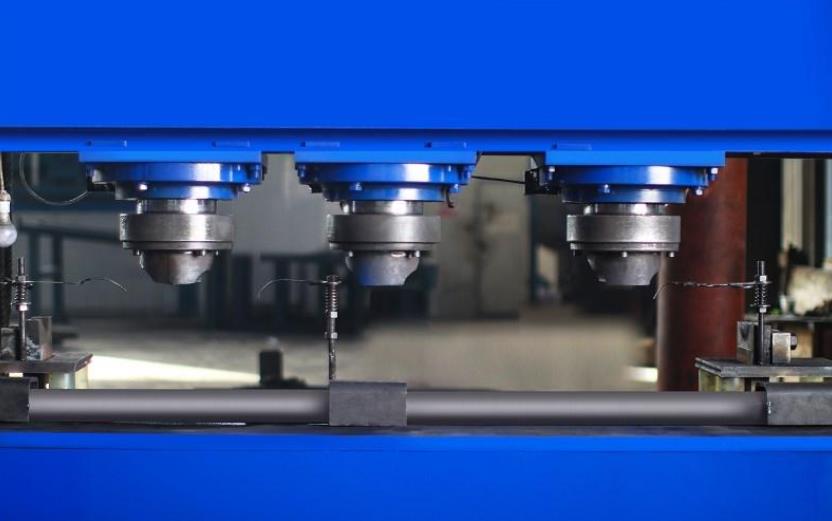

A qualified trailer axle from the material selection, must meet the strength, toughness and other design indicators, and then through hot rolling, shaft head processing, shaft tube forming, quenching, tempering, shot blasting, multi-point straightening, CNC processing, medium frequency induction processing, finishing, welding, painting and other processes, further improve the comprehensive mechanical properties of the workpiece, to ensure the size of the finished product, Finally, the qualified shaft body is assembled with special bearings and hubs. Seemingly simple, but it needs a lot of technology and technology, as long as a link is not up to standard, it will cause a variety of problems for the subsequent use of the owner.

Owners must shine their eyes when choosing, choose qualified axle, in order to better ensure driving safety, let the vehicle performance get the maximum play, reduce the economic loss caused by frequent tire replacement. DARO Group is the first enterprise to mass-produce all-in-one axles in Quanfu Industrial Park, Liangshan. Now it has 20 years of production experience. All the DARO trailer axles produced by it adopt all-in-one axles with stronger strength and higher tenacity, high-strength alloy seamless steel pipe + 15 production processes + online and offline double quality inspection + ultimate performance test. Cost-effective, is a lot of trailer factory, logistics enterprises, transport fleet fixed object of cooperation.