How much is a trailer axle? Why do prices vary so much?

Trailer generally refers to the trailer compartment, whose main function is to load goods, tow and hang behind the tractor, and use the power of the tractor to realize driving. For a trailer, the load-bearing capacity is very critical, and the axle is a key component directly related to the strength of the trailer's load-bearing performance.

How much is the trailer axle on the market? This problem needs to be determined based on factors such as the type, model, and brand of the axle:

For example, for 13t drum axles, most of the prices are concentrated between 3000-4500 yuan, some high prices can rise to about 6000-8000 yuan, and a few cheap ones can also be as low as 2000-2500 yuan;

If it is a disc axle, the price is higher than that of the drum brake axle. The average market price is about 6,000-7,000. The high one can reach 9,000 yuan or even tens of thousands, and the low one can be sold for 3,000 yuan;

If it is a maintenance-free axle, you need to add about 1000-1700 yuan to the price of ordinary trailer axles.

Of course, the final price also needs to consider the specific configuration of the axle, the quantity purchased by the owner, and the market details of the region to which it belongs, etc., which will more or less have a certain impact on the transaction price.

Some car owners may have asked: Why are the prices of trailer axles of the same specification so different? Is there even a trend of polarization? The reasons are nothing more than the following:

1. Raw material of trailer axle

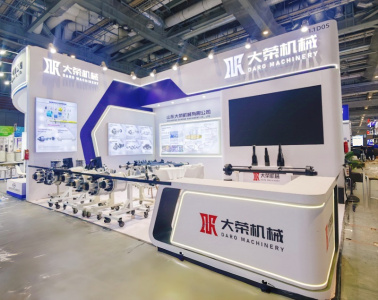

As we all know, the raw material of axles is seamless steel pipes. For example, 20Mn2 high-strength alloy seamless steel pipes are used for the axles of DARO trailers. The strength, hardness, weight, toughness and other key indicators of such steel materials can meet the use requirements of axles.

At present, there are many kinds of steel pipes on the market, and the quality varies greatly. The average price can be as low as 1500-2000 yuan per ton. Of course, there are also differences in quality, especially inferior steel pipes, which may have some problems themselves. These differences in mechanical properties It is difficult to judge with the naked eye. Therefore, in order to save money, some small factories choose those steel pipes with poor quality as raw materials. The production cost is less invested, and the profit margin is naturally large. possible.

2. Production process of trailer axle

How is a qualified axle produced? Taking the DARO trailer axle as an example, starting from the raw materials, it has to go through more than a dozen production processes before it can be shaped, and then it has to go through multiple quality inspection processes such as fatigue testing, salt spray testing, tensile testing, and impact testing. Only after passing the test can it be put into use at the factory. Although such a process is complicated, it can guarantee product quality to the greatest extent and be responsible for consumers.

At present, the trailer axle brands on the market can be roughly divided into two types: one is a brand with a special factory, independent R&D and manufacturing capabilities from raw materials to finished products, a relatively large scale, relatively strong technical experience and strength; It is because they do not have independent production capacity, purchase semi-finished products from other places, assemble them by themselves, or recycle old axles for refurbishment. Most of them are small brands or even three-no brands. In contrast, the latter has a simpler processing process, requires less manpower and material resources, and has poor or even no quality control capabilities for finished products.

There is another point that needs to be noted: there are many axle production processes, and it is difficult to distinguish with the naked eye whether some of the processes are done or not, or whether the standards are up to standard. When purchasing a car, car owners still need to investigate the scale and strength, and try to choose brands that have entered the market early, have many cooperative customers, and have a good reputation among users.

3. Trailer axle brand premium

First of all, let's explain what is called "brand premium". To put it simply, the final price of the same product is different due to the different brand positioning of suppliers. For example, the price of a high-end brand will be high, while the price of a cheap or niche brand will be relatively cheap. Like other commodities, axles also have a brand premium.

Since the development of the domestic axle industry, relevant production testing standards have been established, and key production technologies and processes have basically been popularized. Especially for some axle factories with independent R&D and manufacturing capabilities, the biggest difference in their production line equipment lies in the degree of automation and production capacity. , there is little difference in function. In other words, the production process is not bad.

Due to the different positioning routes of different axle brands, the cultures behind the brands are also different. In extreme cases, the price difference will be obvious. However, car owners need to pay attention to that brand premium is not synonymous with quality and performance. Axle, its quality and performance is not bad.

If the car owner has sufficient budget and is willing to pay for the brand premium, then there is nothing wrong with choosing a high-priced product; if the car owner wants to save the budget, a cheap product with high cost performance is also a good choice. In addition, the axle is a key component of the vehicle after all, and is closely related to safety. Car owners must not always choose products that are obviously lower than the market price with a greedy mentality, otherwise they will be easily deceived by unscrupulous manufacturers.