How to maximize the efficiency of hydraulic retarder?

Hydraulic retarder is a kind of auxiliary brake device, which is generally used in large vehicles.

As we all know, large vehicles have greater weight, and often require more braking force than ordinary vehicles when braking. Once in a long distance downhill section, the brake is prone to temperature rise and heat attenuation under long time friction braking, and it is also easy to lead to brake failure in serious cases. The hydraulic retarder can remove the brake wear and overheating phenomenon caused by long time or frequent braking to a certain extent, and realize the smooth braking of the vehicle.

In fact, the hydraulic retarder is only one of the vehicle retarder, the common retarder also includes the engine retarder, eddy current retarder.

1. The engine retarder belongs to the first-level retarder. After starting, it can change the operation mode of the engine exhaust valve, so that the engine becomes an air compressor to absorb power, and then the deceleration force is transmitted to the driving wheel.

Engine retarder can be subdivided into three types: engine exhaust butterfly valve brake, deflated engine brake and compression release engine retarder.

The braking force of the first stage retarder is small, which can not meet the legal requirements of vehicle braking, and can only be used together with other auxiliary braking systems. In addition, due to loud noise, high maintenance cost, slow failure of transmission shift and other reasons, limited its development and popularity.

2. Eddy current retarder is a two-stage retarder, which uses electromagnetic principle to convert kinetic energy of vehicle running into heat energy to release, so as to achieve the purpose of deceleration and braking.

Eddy current retarder is a kind of non-contact reduction device, usually installed between the transaxle and transmission, with high braking efficiency, short operation response time, non-contact/zero wear/failure rate is very low, can extend the service life of the vehicle brake, reduce the comprehensive vehicle cost, improve vehicle safety, economy, environmental protection, stability and comfort.

However, on the other hand, eddy current retarder is large in size, requires high installation space, has large dead weight, consumes electric energy, has obvious thermal attenuation, and is easily affected by ambient temperature.

At present, the domestic eddy current retarder is mainly installed in buses, passenger cars, these two fields are mostly used, especially some high-end buses are almost installed eddy current retarder.

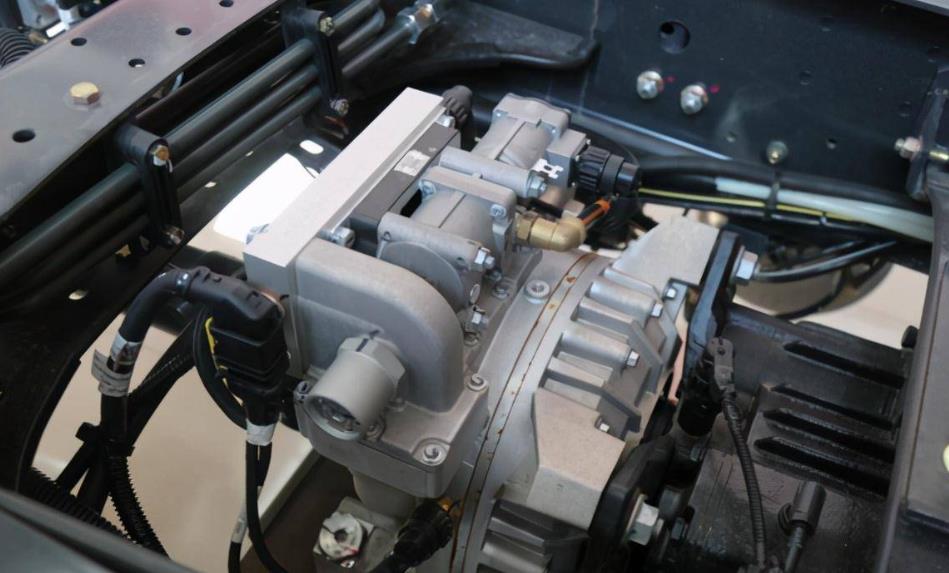

3, hydraulic retarder is also a two-stage retarder, first appeared in Germany, is used in the train to assist deceleration, later used on the truck.

According to the different medium, the hydraulic retarder can be divided into oil medium and water medium. At present, the most common retarder on the market is the oil medium, the market price is generally about 10,000 to 30,000 yuan; Water retarder has the advantages of smaller weight, faster response speed, large torque, less power consumption, convenient maintenance, etc., but the price is on the high side, generally about 30,000 to 50,000 yuan. In addition, there are many technical difficulties in lubrication and high temperature evaporation and other problems, so it has not been popularized.

In order to take into account the installation needs of different types of trucks, buses, light trucks, special vehicles and so on, the hydraulic retarder has launched series, parallel, independent installation mode, owners can choose freely according to the model.

It is worth mentioning that the market share of hydraulic retarder used to be far behind eddy current retarder, but with the continuous improvement of related technology, the price difference between the two is becoming smaller and smaller. Hydraulic retarder can provide greater braking torque with smaller mass, and the continuous braking ability is strong, simple maintenance, less cost, good cooling effect, stable auxiliary vehicle braking at the same time, It can also reduce the wear of the main brake, prolong the service life of the tire, improve the operating efficiency of the vehicle, and reduce the cost of the comprehensive vehicle.

Some people think hydraulic retarders are just for long downhill runs. This idea is true, but inaccurate, if only in long downhill use, then the use of the liquid is at most half the value of use. Owners can in some predictable non-emergency braking situations, such as toll stations, traffic lights, traffic jams and other sections, in advance to collect fuel, move the brake handle to slow down, in order to reduce the number of brake.

The DARO trailer axle reminds owners,It is forbidden to use liquid retarder when in neutral. It is also necessary to use/disable hydraulic retarder when encountering wet, snow and ice or dark ice road. If the use of liquid slow can not achieve deceleration, such as when the vehicle is fully loaded downhill, liquid slow has been in constant speed gear, the vehicle speed is constantly increasing, then the main decisive step on the brake pedal brake, do not directly dial the liquid slow to the highest level, because the liquid slow to the highest level suddenly into the full state, easy to lead to excessive slow down, cause the vehicle rolover. In addition, the water temperature will rise sharply, resulting in continuous high temperature and loss of braking force. Therefore, although the liquid delay is good, it also needs to be properly applied.