How many kinds of semi trailer suspension?

Suspension, also known as suspension, is the general name of all the force transmission connection devices between the frame and the axle of the semi-trailer, used to transfer the force and force torsion between the wheel and the frame, buffer the impact force from the road to the frame or body, and reduce the vibration caused by the car, to ensure that the car can run smoothly.

In general, trailer suspension can be divided into four main types:

1. Rigid suspension.

The chassis of the rigid suspension directly acts on the axle between the wheels. There is no spring as a buffer. When the road is uneven, it completely relies on the swing of the balance beam to maintain the relative balance of the front and rear axles.

This kind of suspension is relatively rare at present, because its shock absorption effect is very poor, mainly used in low speed cargo carrying flat semi-trailer.

2. Steel plate suspension.

Also known as tandem steel leaf spring balanced suspension, is also a common steel leaf spring suspension, mainly composed of steel leaf spring, suspension support, connecting rod, U-bolt and so on.

The biggest advantage of this trailer suspension is low cost, reliable work, easy maintenance. Because of this, the steel plate suspension is currently the largest proportion of semi-trailer applications in the country, about 70-80%.

3. Single point suspension.

That is, the common leaf spring before and after bracket is reduced into a single bracket connected to the body, which can bisect the force point to different axles, so the bearing capacity is greater, generally used on heavy trailers.

4. Air suspension.

Also known as air bag suspension, its most notable characteristic is the air bag type air spring, compared with other suspension, air suspension buffer force is better, can effectively protect the cargo, improve the driving comfort, is mainly used for precision instruments, dangerous chemicals and other transportation.

According to the motor vehicle operation safety technical conditions GB7258-2017, the three-axle plate plate, warehouse grid type semi-trailer must be installed disc brakes and air bag suspension in order to be successfully licensed or on the road. So what's so good about air suspension?

Advantages of air suspension:

1. Good shock absorption effect. Compared with the traditional leaf spring, the air bag is obviously softer and more comfortable. It forms a soft connection between the frame and the axle, and the bumps and shocks from the road can be greatly relieved. In addition to enhancing the driving comfort, it is also a protection for the cargo.

2, reduce the load stress. The compressibility of air makes the airbag suspension easily cope with the bumps on the road at the same time, it can reduce the load stress, prolong the service life of the axle and semi-trailer, and reduce the cost of using the vehicle to a certain extent.

3. Less weight. Lightweight is a development trend of the trailer accessories industry at present. Compared with the traditional suspension, the air suspension has lower weight, which can obtain more free weight space for the users of the standard load, and the users of the no-load can save fuel, energy and efficiency.

4, long service life. The mass of the air spring itself is relatively light, the air medium friction in the air bag is also relatively small, the service life can reach 2-3 times of the leaf spring, to help the owner better save costs.

Air suspension has many advantages, but objectively there are also some disadvantages:

1, compared with other suspension, the structure of air suspension is more complex, because to use air spring, must be set to transfer a variety of other forces and moments outside the vertical force of the rod system, which also leads to a certain extent, its price is relatively high.

2, and the price is high corresponding to the maintenance cost. In addition, compared with traditional leaf springs, the material of the air bag is more likely to be damaged, and the maintenance cost can not be underestimated.

3, once the air suspension failure, can not continue to drive, can only call trailer service. Unlike traditional suspensions, oil leaks can still make it to a maintenance point.

4, the air suspension buffer is good, but in the case of full load, the brake or start will appear nodding or tailing, but also need skilled driving skills.

Although the advantages and disadvantages of air suspension coexist, the overall consideration is more obvious, or air suspension will not become the official designation of the necessary suspension. In addition, today's commercial vehicle industry "lightweight" prevailing, shipper for cargo damage more and more attention, competition between peers is becoming more and more intense, so the industry background also to a certain extent to promote the use of air suspension.

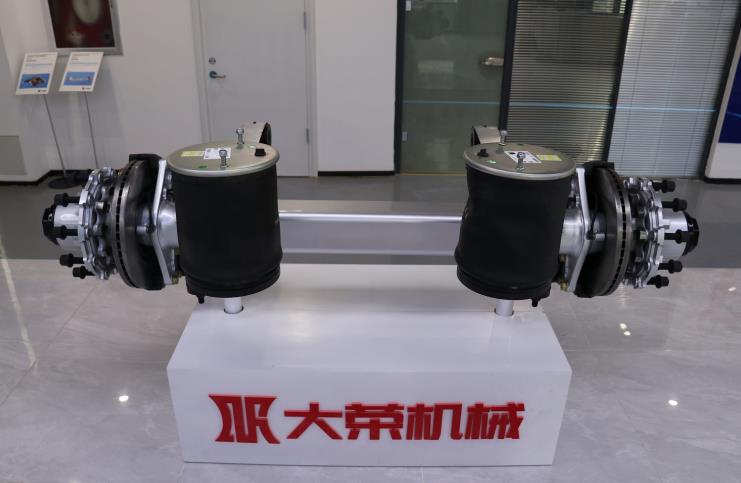

It is recommended that the owner try to choose a reliable brand when buying air suspension, which can also reduce the cost of follow-up maintenance and replacement to a certain extent. The air suspension produced by DARO is composed of air spring, shock absorber, height control valve, guide arm, follow-up steering mechanism, etc., using 3D forming technology, stronger bearing capacity, special seals can fully ensure the temperature of suspension working, prolong the service life, parts assembly design is more flexible, installation time is shorter, but also can be maintained according to the actual situation. Reduce maintenance costs.