How to install the trailer ABS system?

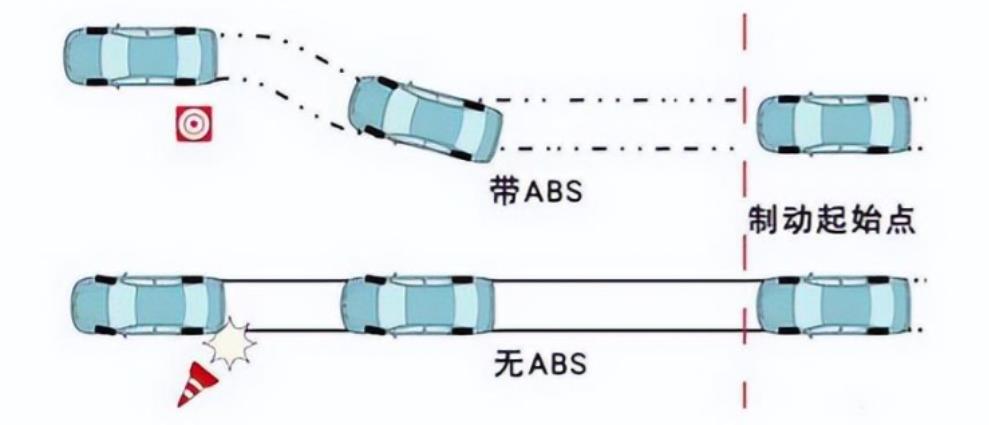

ABS, also known as anti lock braking system, is a device that prevents wheel lockup and maintains dynamic friction between the wheels and the road surface during vehicle braking. After installation, it can improve the braking efficiency of the vehicle, enhance driving safety, and also reduce the cost of vehicle maintenance to a certain extent.

In general, the basic components of an ABS system mainly include sensors, combination controllers, wheel speed sensors, main suspension connection harnesses, and various sensor connection harnesses.

As we usually say, "four channels" and "six channels" are commonly referred to as ABS sensors. "four channels" refer to four sensors that control the wheels on both sides separately; The 'six channels' refer to six sensors, each axle equipped with an independent control unit. So the six channel ABS monitoring and control needs to be more precise, and of course, the purchase cost will also be higher. If the car owner usually runs on highways, national roads, and provincial roads, choosing a four channel ABS can basically meet the usage needs. However, if the driving conditions are more complex, it is best to choose six channels for safety reasons.

How should ABS be installed? Next, let's have a brief chat.

1. Dismantle the tire and wheel hub

2. Installing the gear ring

There are two main ways to install the gear ring:

One method is to place the wheel core in a horizontal position, place the gear ring, and press it down smoothly with pressure. Generally, professional equipment is needed, otherwise the horizontal stability cannot be controlled well;

The other belongs to the heating method, which heats the gear ring to 180 ℃ - 200 ℃, and completes the assembly through the principle of thermal expansion.

When heating the gear ring, ensure that the heating is uniform, and then heat it onto the installation step of the wheel hub gear ring. Be careful not to directly hit the surface of the gear ring with a hammer to avoid deformation of the gear ring. You can use a wooden block or other object to pad it.

3. Welding sensor bracket

Find the welding position of the sensor bracket and weld it to the vertical center of the axle, which is about 8mm higher than the axle. Ensure that the sensor probe can maintain a gap of<0.7mm with the gear ring after being inserted into the bracket.

4. Install the wheel hub, brake drum, and wheel

Be careful not to push the wheel hub directly to the bottom to avoid damage caused by the gear ring hitting the sensor. Reserve a certain amount and then slowly tighten it to the bottom with a nut.

5. Fixed combination controller

Fix the combination controller to the frame, paying attention to the following points:

The exhaust outlet must be vertically downwards;

The minimum inner diameter of the pipeline from port 1 of the controller to the air reservoir is 12mm;

The minimum inner diameter of the pipeline from port 2 of the controller to the brake chamber is 9mm;

Try to fix it in the middle of the three bridges as much as possible, so that the distance between the connecting air pipes of each compartment and the controller is shorter and equal.

6. Route ABS wire harness

You can use a gas tube to wrap the wiring harness, improving its wear resistance and extending its service life. Reasonable layout and firm binding to prevent line wear caused by vehicle bumps.

After completing the above steps, the trailer ABS system is basically installed. If possible, it is best to find professional equipment for computer testing to verify whether each step is installed correctly to avoid affecting subsequent use.

It is worth noting that some car owners are accustomed to using the "brake king" and are accustomed to lightly pressing the brake pedal when braking; The ABS system, on the other hand, belongs to an automatic braking program. After starting, the brake pedal will rebound upwards, causing the wheels to roll and slip, maintaining maximum adhesion to the road surface, while also possessing maneuverability. If the car owner steps on and releases it, it often won't have its effect, and they must step on it to the bottom.

In addition, the ABS system does not have strict requirements for the type of axle, and both drum and disc axles can be used together. However, due to the slower braking response speed of the drum brake axle compared to the disc brake, the braking frequency is also not as fast as the disc brake, which to some extent affects the ABS system's ability to change lanes during emergency braking. From this point, in order to maximize the effectiveness of ABS, it may still need to be paired with the disc axle.