How does the electro-mechanical braking system brake?

With the continuous development of vehicle technology, people's requirements for vehicle safety are getting higher and higher, and vehicle brake systems are constantly upgraded and improved, from drum brake to disc brake, and then to ABS, EBS and other auxiliary brake systems, emerging brake technologies emerge in an endless stream, and electronic mechanical braking has slowly begun to appear in people's vision.

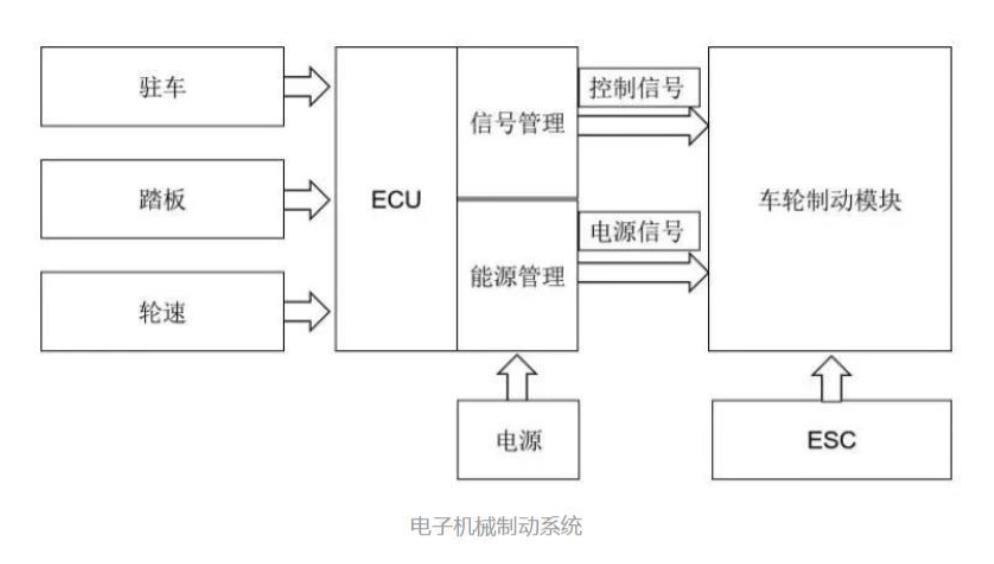

Electromechanical Brake (EMB) is the abbreviation for electromechanical brake, which is mainly used in aircraft, such as the F-15 fighter jet in the United States, and gradually developed into vehicles. Its biggest feature is that it cancels the air storage cylinder, brake air chamber, hydraulic pipeline and other components, realizes the complete electronic signal transmission between the pedal signal and the actuator, and achieves the integrated control of the vehicle chassis with ABS, TCS, ESC and other modules, which belongs to the real sense of the line control dynamic system.

We all know that the brake medium used in the traditional air brake is air, which pushes the brake pad to work after pressure, and if the air pressure is insufficient, the braking force cannot be obtained. The brake medium of the oil brake is the special brake oil, when the brake pedal is pressed down, the piston and seal bowl in the brake master pump will be pushed, and then the oil is transmitted to the piston of each brake branch pump through the push rod, in order to promote the brake pad to work.

The EMB system no longer requires air or hydraulic oil as a medium, and its braking torque is completely dependent on the motor installed on the tire to drive the execution, when the owner steps on the brake pedal, the controller will transmit electronic signals to the motor, the drive works, and the brake pad is driven by its own rotation to achieve the deceleration or stop of the vehicle.

With fewer components, the structure is more simplified, which also brings many advantages:

1, more convenient installation and maintenance.

The system has fewer parts, the design composition is more concise, the installation space requirements are more relaxed, the owner is less difficult to arrange, and the subsequent maintenance and maintenance of the system is also simpler.

2, the system failure rate is reduced.

The more the number of parts, the higher the failure rate, after all, any part of the problem will lead to the whole body, from this point of view, the EMB system failure rate is relatively small.

3. The weight of the vehicle decreases.

The configuration is streamlined, and the weight is reduced, which can not only provide more compliant loading space for the vehicle, but also improve fuel economy, reduce engine load, and make the fuel vehicle more fuel-efficient and the new energy vehicle electric storage range longer.

4. Braking efficiency is improved.

This point is mainly from the perspective of energy conversion and transmission. Whether it is the air brake or the oil brake, from the owner to step on the brake pedal to drive the brake pad friction brake, the middle needs to go through a number of system components, after multiple energy conversion and transmission, the more the number of energy conversion and transmission, the higher the loss, affecting the final braking efficiency. The EMB system replaces the traditional gas/oil circuit with an electronic control line, which can shorten the braking response time, increase the braking deceleration, reduce the braking distance, and optimize the control of wheel slide.

5, compatible with other systems.

Various instructions of EMB system are transmitted by electrical signals, which is easy to be incorporated into the controller local area network bus, compatible with ABS system, ADAS (Advanced Driver Assistance system) and other electronic control functions, and can effectively avoid the brake pedal caused by triggering ABS repeated rebound, improve driving comfort.

In theory, the EMB system has many advantages, and it can also ban media such as oil, which is more in line with environmental protection trends in the long run. From an objective point of view, EMB is not currently in mass production, more in the research and development and concept stage, its actual use efficiency, there is a lack of a large number of market data to support. In addition, the EMB system is not without shortcomings, in terms of technical aspects alone, there are many questions:

1, the EMB system needs to consume a lot of electricity when working, can the power supply widely used on the vehicle meet its needs?

2, although theoretically speaking, the EMB system failure rate is low, once its line or power supply problems, how should the braking system protect the braking performance?

3, heat dissipation efficiency for the brake system is a test, EMB is no exception, when the vehicle for a long time at high speed, or in long downhill road conditions requiring frequent braking, how will the heat generated by the EMB system diverse? And how to ensure its thermal stability?

4, although the structure of the EMB system is simple, it is inevitable that there are some more sophisticated electronic circuits, if the use of the vehicle is more complex, or often access to the working environment with magnetic field, EMB system can not be disturbed?

5, the sensors, chips, circuits required in the EMB system compared to the current gas and oil circuit cost is much higher, in the current freight market environment, and how many owners are willing to pay for it?

It can be seen that although the EMB system is tall, it seems to have the advantages and prospects that the traditional brake system can not reach, it can be divorced from the actual application is a paper talk, and the actual how to wait for the actual feedback of the market.