How to classify driving axle, steering axle and supporting axle?

Axle is a very important part of the trailer, bearing the driving, steering, bearing, driving and other functions of the trailer, can be said to be the walking system of the trailer.

Usually, according to the different drive mode, axles can be divided into steering axle, drive axle, steering drive axle and support axle. Among them, the steering bridge and the support bridge are both driven Bridges, that is, they do not have the driving function. At present, most trailers use the front front drive, the front axle, that is, the axle of the tractor, assumes the steering drive function, and the rear axle mainly plays the bearing support function.

Trailer axle classification and structure:

1. Steering bridge.

The steering axle is usually located on a trailer tractor, so it is also called the front axle. It is basically the same structure, consisting of two steering knuckles and a beam on which the wheels are mounted. When turning, the steering knuckle makes both ends of the wheel deflect at a certain Angle to achieve vehicle steering.

Generally, in addition to the steering function, the steering bridge of the trailer should also bear the torque caused by longitudinal and lateral forces.

2. Drive axle.

The function of the drive axle is mainly to distribute the engine torque to the left and right driving wheels after reducing the speed and increasing the torque, changing the direction of power transmission, and driving the vehicle. Generally, it is mainly composed of the reducer, differential, half shaft and axle housing. If classified according to the structural form, it can be divided into integral drive axle and broken drive axle, but the integral drive axle is generally used in freight vehicles.

(1) integral drive axle, the use of non-independent suspension, drive axle housing is a rigid whole, both ends of the drive axle through the suspension and the frame is connected, the left and right half shaft is always in a straight line, that is to say the left and right driving wheel can not achieve independent beating. When one side of the wheel bumps on the road, the transaxle and the body should be followed by jumping or tilting.

(2) disjointed drive axle, using independent suspension, its main reducer is fixed on the frame, the front axle is the front auxiliary frame, both ends are connected with the frame through the up and down swing arm, the half axle is also connected through the universal joint. So the driving wheels on both sides can beat independently of each other. Generally more widely used in passenger cars.

3. Steering drive axle.

Understand the steering axle and drive axle, steering drive axle is better to understand, its structure should have the general drive axle with the main reducer, differential and half shaft, also have the steering axle with the knuckle and kingpin, mainly bear the steering and drive function.

4. Support the bridge.

Usually referred to as the trailer axle refers to the support bridge, used in the trailer after the tractor, the main role is to bear the body weight, buffer road bumps, ensure vehicle braking, maintain vehicle driving.

(1) DISC brake AXLE

The most important features of DISC brake AXLE are that the brake disc is exposed and the heat dissipation is fast. When the trailer braking continuously, the temperature will not be too high to avoid brake failure. Compared with Drum brake axle, brake AXLE is more sensitive and stable, which is conducive to the protection of cargo and the reduction of cargo damage. In addition, DISC brake AXLE is also the axle type that is forced to be installed on three-axle warehouse fence plate trailer. But some heavy vehicles require hydraulic retarders to use the DISC brake AXLE.

(2) Drum brake axle

Drum brake axle features sealed brake drum, brake pad friction area is larger, can obtain stronger braking force, so it is more suitable for heavy transport vehicles. But also because of its sealed brake drum, poor heat dissipation, in order to avoid heat attenuation, need to be equipped with water spraying device, continuous braking water cooling.

(3) LOW BED TRAILER AXLE

LOW BED TRAILER AXLE is mainly applied to low flat trailer. As it is often used for transporting heavy loads, it requires more load-bearing capacity and stability of axle. Therefore, LOW BED TRAILER AXLE generally has lower ground height than ordinary axle, which can reduce the center of gravity and improve stability on the one hand, and facilitate loading and unloading of goods on the other hand. The AXLE body and axle housing of LOW BED TRAILER AXLE need to be strengthened to ensure its heavy-duty performance.

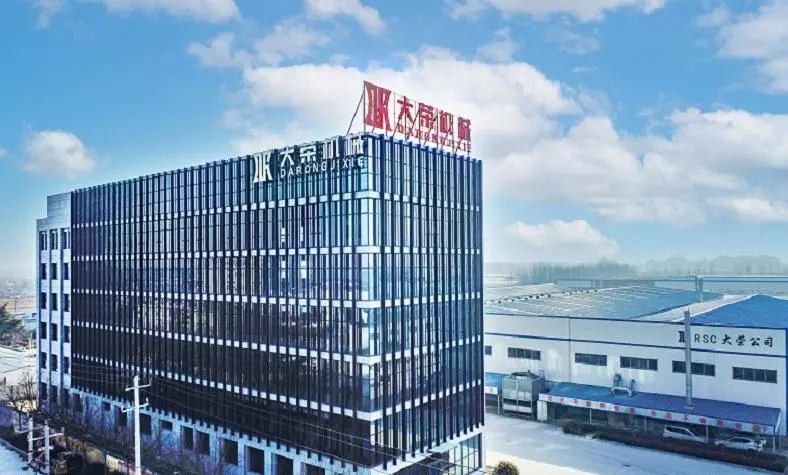

DARO Group is located in Quanpu Industrial Park, Liangshan. It is one of the first trailer axle enterprises to mass-produce the all-in-one axle body in China, and its axle casting technology and process are at the leading level in China. DARO Group has a 32000 square meters of standardized plant, from the next to the assembly of more than a dozen processes in accordance with industry standards and specifications, the factory axle are through the online + offline double quality inspection and ultimate performance test, reliable and reliable quality, since its establishment, the group always adhere to the cost-effective route, aiming to let users with more affordable prices to buy higher quality axles.