How to carry out daily maintenance and upkeep of trailer axles?

The axle is the most core component assembly on a trailer, directly related to the vehicle's load-bearing, braking, and driving. If there is a problem with the axle, the safety, attendance, and economic benefits of the vehicle are almost empty talk. Therefore, it is particularly important to do a good job in the daily maintenance and upkeep of the axle.

If the car owner is familiar with the structure, function, and various components of the axle, daily maintenance and upkeep can be done by themselves, and even some common small faults can be eliminated by themselves. This can not only save the time for sending the vehicle for repair, but also save expenses and costs to a certain extent. However, compared to other components, the structure of the axle is relatively complex, which to some extent leads to a relatively large workload of maintenance. Only with certain knowledge or technology can this work be better completed.

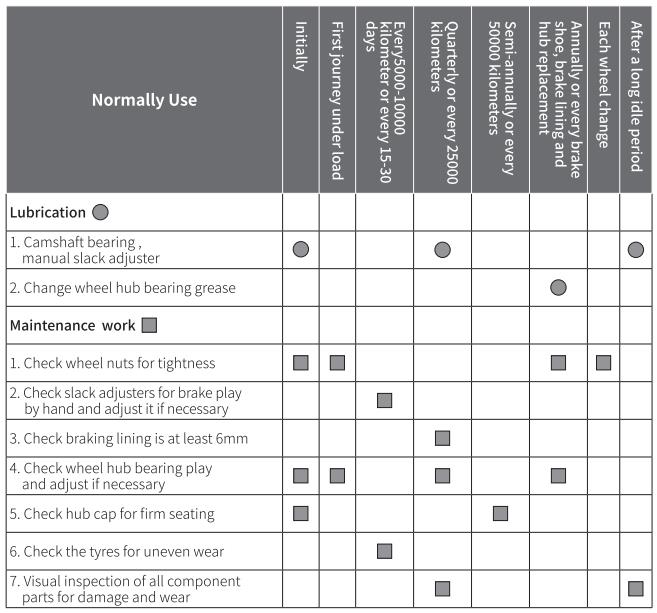

To this end, Darong Axle has specially summarized and sorted out the maintenance and repair items of the axle in daily use and some common troubleshooting methods for car owners, for your reference.

Daily inspection and maintenance of axles

Before vehicle operation, it is necessary to conduct various safety checks to avoid or prohibit driving with faults. The main inspection contents include: the tire pressure, the fastening of the wheel and the main bolts and nuts of the suspension system, whether the leaf spring or the main beam of the suspension system is broken, the working conditions of the lighting and braking systems, the pressure conditions of the braking system and the air suspension system, etc.

Every two weeks or when encountering frost weather, it is necessary to open the drain valve at the bottom of the air storage cylinder to drain the accumulated water.

If it is a newly replaced new car or a new axle, after the initial load driving, it is necessary to check the fastening status of the bolts and nuts of the wheels and suspension system to ensure that the specified torque can be achieved.

1. Check the wheel nuts: After the first load driving of a new car or after changing the wheels, it is necessary to check the fastening of the wheel nuts/inserts to ensure that the specified torque is achieved.

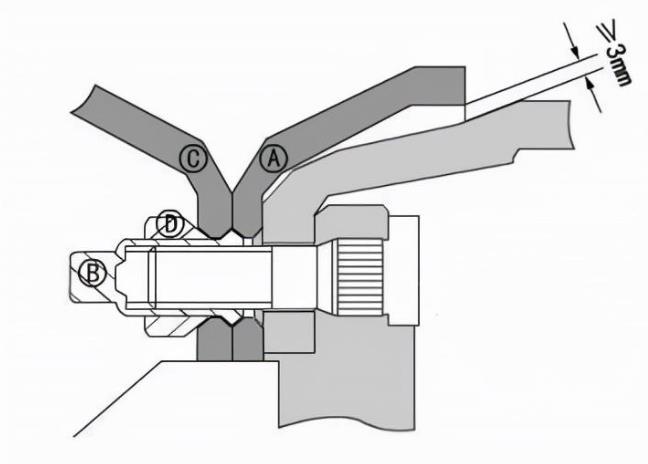

Method: Loosen nut D, tighten screw insert B, and install and tighten nut D.

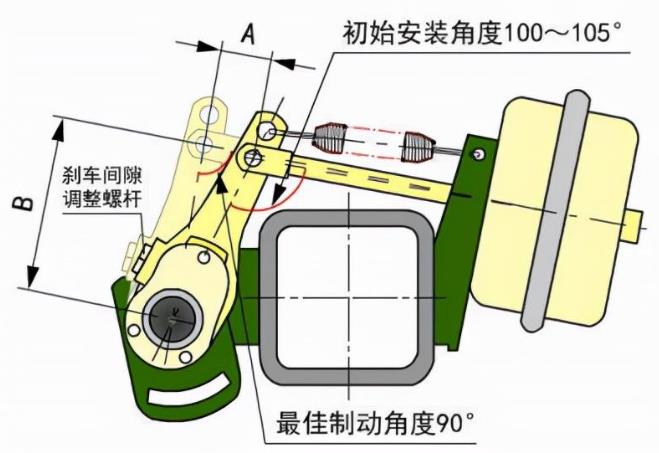

2. Check the adjustment arm: It is recommended that the initial installation angle of the adjustment arm be between 100 ° -105 °, and the optimal braking angle is 90 °. According to the usage of the vehicle, adjust it every 15-30 days or every 5000-10000 kilometers.

Method: Pull the adjustment arm. If the stroke A of the air chamber push rod is ≥ 35mm, the brake clearance of the axle needs to be adjusted; Turn the clearance adjustment screw clockwise until the brake locks, and then turn it counterclockwise by 90 ° -120 °; Alternatively, the screw cap of the adjusting arm brake clearance adjustment screw can be used to adjust the A value to 13% -20% of the B value of the brake arm length.

3. Check the brake shoe friction plate: It is recommended to check the thickness and looseness of the brake friction plate every month or every 10000 kilometers. If the thickness of the friction plate is found to be less than 5-6mm or if there is looseness, the friction plate must be replaced. The friction plate can be inspected through the observation hole of the dust cover.

4. Check the brake drum: Check the brake drum regularly every 3 months or depending on the vehicle's usage. When the inner diameter of the brake drum is less than 422mm or there are continuous cracks on the friction surface, the brake drum should be replaced in a timely manner.

5. Check the clearance of wheel hub bearings: New cars must check the clearance of wheel hub bearings every three months, and it is recommended to check it frequently for non new cars. During the inspection, the axle can be lifted to lift the tire off the road, two pry bars can be inserted between the tire and the ground, and the wheels can be rotated in both positive and negative directions to check whether the sound is smooth, whether there is noise, and whether the noise increases with speed.

6. Check or adjust bearing clearance:

Double axle head series: loosen the wheel hub cover; Remove the shaft head split pin; Use a special wrench to rotate the wheel hub and tighten the shaft head nut to a specified torque of 350Nm to 400Nm; Reverse the rotation of the nut 1/7-1/6, aligning the nut groove with the cotter pin hole; Insert a new split pin and bend the tail of the pin by 30 ° -45 °; Install the wheel hub cover and tighten it to a torque of 80Nm to 120Nm.

German axle head series: loosen the wheel hub cover; Remove the shaft head split pin; Use a special wrench to tighten the shaft head nut with a minimum torque of 380 ± 10Nm, while rotating the hub in the opposite direction; Loosen the nut one turn back; Tighten the shaft head nut again with a torque of 70 ± 5Nm/90 ± 5Nm; Align the groove of the shaft head nut with the cotter pin hole; Insert a new split pin and bend the tail of the pin by 30 ° -45 °; Install the wheel hub cover and tighten it to a torque of 80Nm to 120Nm.

Large and small shaft head series: Loosen the hub cover bolts and remove the hub cover; Align the two teeth that are locked by the locking gasket; Remove the locking nut, locking washer, and locking washer; Use a wrench to tighten the shaft head nut to the specified torque of 373 ± 10Nm while rotating the wheel hub; Loosen the shaft head nut by one turn; Tighten the shaft head nut again with a torque of 102 ± 5Nm; Install the stop washer and loosen the 4.5 to 5 stop washer holes on the shaft head nut; Install locking washers and locking nuts, tighten the locking nuts to the specified torque of 373 ± 10Nm; Flip the two teeth of the locking gasket and lock it tightly; Install the wheel hub cover, washer, and bolt, and tighten to the specified torque of 20-25Nm.

7. Axle lubrication:

Camshaft bushing: It is recommended to add lubricating grease every quarter or after maintenance, or to add it in advance according to actual usage until lubricating grease overflows around.

Tapered roller bearings: It is recommended to add lubricating grease every six months or after replacing the brake shoes, friction plates, and wheel hubs. Alternatively, it can be added in advance according to the actual situation. When filling, it is necessary to thoroughly clean the bearings and check for defects such as pitting, peeling, and wear. If there are any defects, they should be replaced in a timely manner, and then sufficient lubricating grease should be added.

Hub cavity: It is recommended to fill it every six months, or after maintenance and replacement of the hub, or fill it in advance according to actual usage. Pay attention to thoroughly cleaning the inner cavity of the wheel hub, and then add an appropriate amount of lubricating grease.

Common axle faults, cause analysis, and troubleshooting methods: