How can trailers achieve cost reduction and efficiency increase through the axle?

In daily life, we sometimes see or hear the term 'towing a trailer'. What is' towing a trailer '? To be precise, there are generally two explanations for 'towing a trailer':

One type is a noun, referring to a type of freight vehicle that has no driving force and is mainly used for load-bearing purposes. It requires the traction of the front of the vehicle to drive, and can also be called a trailer, such as a trailer or semi trailer.

Another type is a verb, which refers to vehicles towing trailers on the road, such as the traffic regulations that state 'vehicles are not allowed to tow trailers during the internship period'.

Trailer is a relatively commonly used model in the logistics and transportation industry, especially with the continuous development of China's transportation industry. With its large transportation capacity and wide range of goods, trailers are gradually favored by more and more logistics companies.

On the other hand, China's road transportation market is huge, but the terrain and climate are diverse, and the road conditions are relatively complex. In addition, the continuous introduction of relevant standards and regulations has put forward higher requirements for the reliable operation, attendance rate, and transportation efficiency of trailers. This has also led more and more trailer accessory manufacturers to move towards cost reduction and efficiency improvement.

As one of the key components of a trailer, can the axle also achieve cost reduction and efficiency increase?

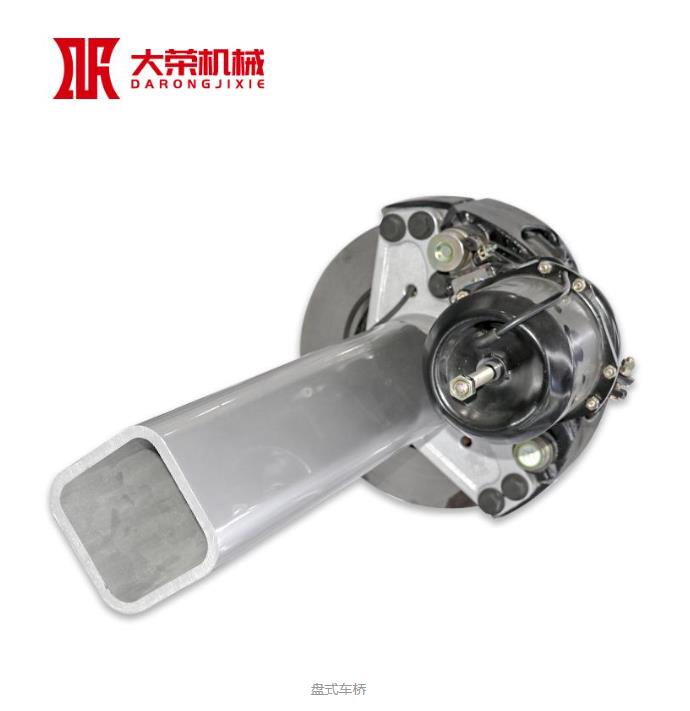

The answer is yes, just like the GB7258-2017 standard for motor vehicle operation safety, which was introduced last year, requiring the installation of three axle guardrail and grille semi trailers to use disc brakes and airbag suspension, which is actually a means of reducing costs and increasing efficiency.

Realize multi cargo within the specified range of lightweight axle design

In the design and production of trailers and tractors, lightweight has always been an important means of reducing costs and increasing efficiency. After all, only when the vehicle's self weight is reduced can more weight space be left to load goods within the specified range.

According to relevant data, the axle weight of a three axle trailer is almost 20% or more of the total weight of the trailer. Therefore, achieving lightweight axle and axle is crucial for trailer weight reduction.

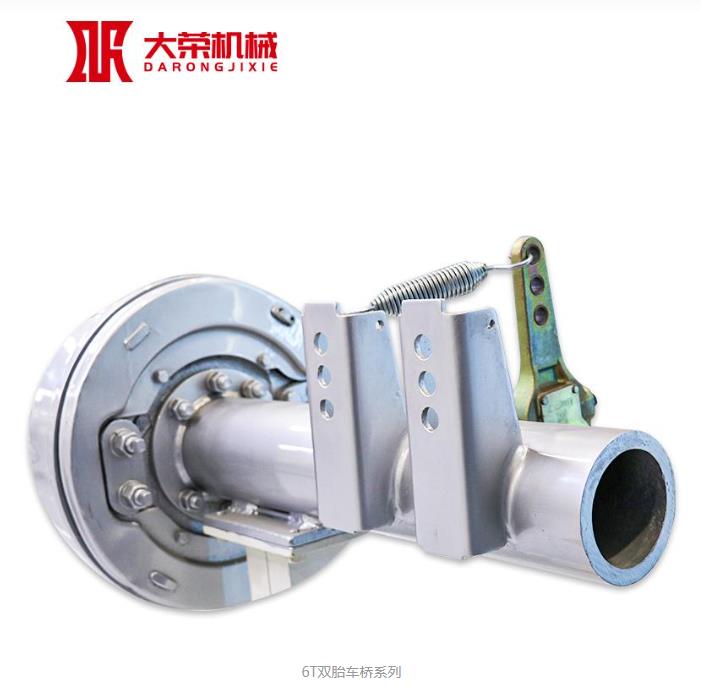

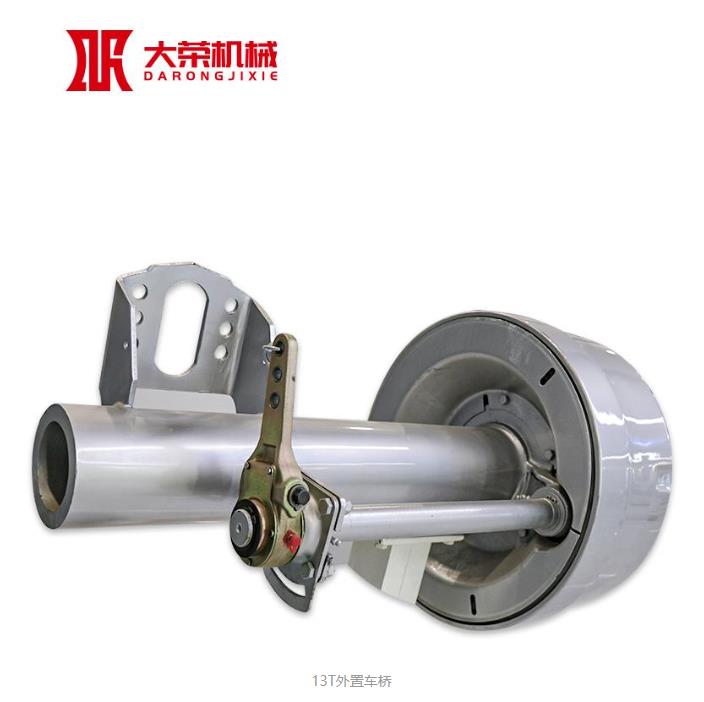

However, compared to the lightweight design of other components, reducing the importance of the axle is more difficult because the axle itself is a load-bearing component. While achieving its own weight reduction, it also needs to ensure that its load-bearing performance does not decrease. Otherwise, it may not be worth the loss. Not only can it not save fuel consumption and increase usage efficiency, but it can also lead to a decrease in load and transportation revenue. This puts forward quite high requirements for the raw materials, production technology, and production technology of the axle. The Darong axle is a typical representative of lightweight design leaders. The 13T axle designed and produced by Darong Group reduces the weight of the same specification axle by about 15% compared to other manufacturers in the same industry. It is made of 20Mn2 high-strength alloy seamless steel pipe combined with one piece heat treatment molding technology and powder spraying+electrophoresis process, which not only reduces the weight of the axle, but also solves problems such as axle deformation and bending under high-strength load, greatly improving strength and toughness.

Protecting goods and tires to reduce vehicle usage costs

If it comes to which component of a trailer has the highest frequency of maintenance, it may not be the tires. After all, the weight borne by the axle from the body is dispersed across the various wheels. If a tire malfunctions, it can increase fuel consumption or affect driving, and in severe cases, it may lead to safety accidents. Therefore, the issue of tires cannot be underestimated.

According to relevant statistics, tire costs directly account for 4% -5% of the operating costs of logistics fleets, while tire participation costs are around 35%. It can be seen that protecting tires and reducing their maintenance frequency is an important way to reduce costs and increase efficiency for trailers. The axle, as an axle assembly, is one of the factors that directly affect the tires.

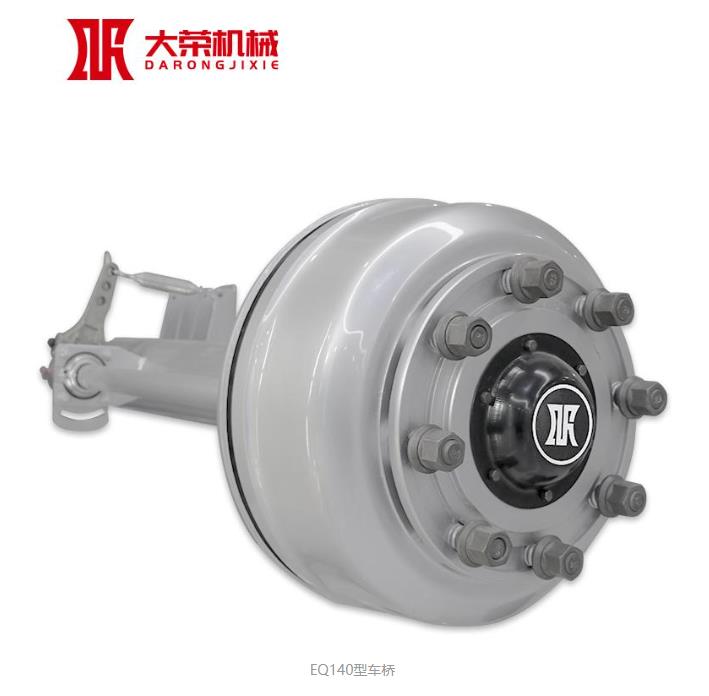

The axles produced by Darong Group fully consider practical needs in design and adopt a 1 degree outward tilt design. Although it may appear to be only a small angle, it can make the tires better fit the road surface when the vehicle is fully loaded, with more uniform force, stronger grip, and greatly improved traction efficiency.

The air suspension produced by Darong Group adopts 3D forging forming technology and adds specialized shock absorbers to improve toughness. At the same time, the buffering force is stronger, which can better protect goods and increase seismic performance. The types of goods that car owners can transport have been expanded, achieving "no picking".

Convenient maintenance and operation to reduce daily maintenance costs

As a freight transport vehicle, the daily maintenance and upkeep of various accessories on trailers are indispensable, especially the axle system, which directly affects the safety and efficiency of trailers. Regular maintenance cannot be ignored.

However, from another perspective, when car owners send their vehicles to specialized repair and maintenance outlets for a single repair and maintenance, it takes about 2-3 hours. If the repair is done 5-6 times a year, it also has a significant impact on attendance and puts cost pressure on car owners.

However, safety is no small matter, and daily maintenance and upkeep are absolutely indispensable. In response to this phenomenon, Darong Group has developed and produced axles with longer maintenance cycles, simplifying the maintenance process, effectively reducing user downtime, and improving operational efficiency.

Extended service life of second-hand trailers with higher value

The axle is the core component of a trailer, and it is a concern for buyers when purchasing new or used cars.

The axles produced by Darong Group have outstanding performance in lightweight design, cargo protection, tire protection, and simplified maintenance procedures. At the same time, they have made significant progress in extending their service life. Not only can they better ensure safety during vehicle use, but they can also endow vehicles with higher economic benefits during vehicle transfer.