Disc brake can be divided into clamp disc type and overall type

Disc brake is a disc trailer axle (disc brake bridge) installed on the use of the development device, with fast heat dissipation, rapid braking response, light weight, simple structure and other advantages, thermal decay and water decay resistance performance, braking effect is stable, so widely used in all kinds of small passenger cars.

With the continuous development of vehicle technology and the continuous improvement of relevant regulations, some commercial vehicles such as three-axis fence plate, three-axis warehouse grid, hazardous chemical transport vehicles and other models, and some high-end and new commercial vehicle models have gradually begun to use disc brake.

The rotating element in the friction pair of disc brake is a metal disc with end work, which is commonly known as the brake disc, and the brake disc is tightened from both sides through the friction element to generate friction to form the braking effect.

Common disc brakes can be divided into two types: clamp disc type and overall type.

First, clamp tray type

Caliper disc brake is currently used in most cars and light trucks in a wide range of applications, with strong heat dissipation efficiency, good thermal stability, the rotating component is the brake disc, the fixed component is the brake caliper, according to the brake caliper movement mode, it can be divided into fixed caliper disc brake and floating caliper disc brake.

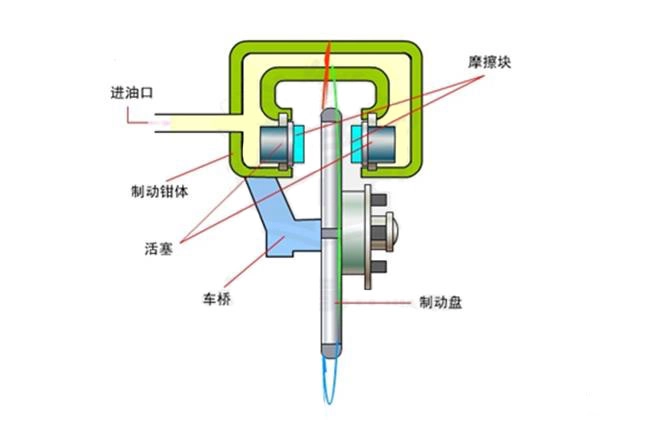

1. Fixed clamp disc brake

The fixed clamp type brake calipers are fixed to the trailer axle and cannot be rotated or moved. Two pistons are installed in the brake caliper, respectively on both sides of the brake disc, when the driver presses the brake pedal, the brake wheel cylinder hydraulic rise, the piston is slightly pushed out, and the brake liner tights the brake disc to brake, in simple terms, the working principle of the fixed caliper disc brake is similar to the brake of a bicycle.

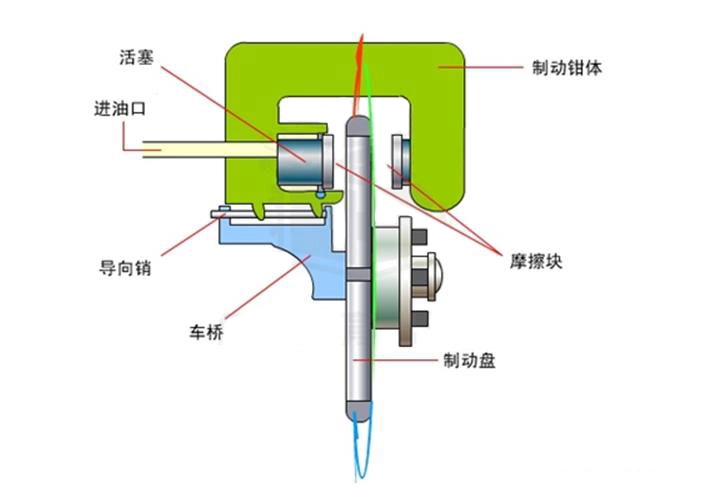

2, floating clamp disc brake

The brake caliper of the floating caliper disc brake is connected to the axle housing through the guide pin, which can realize axial sliding relative to the brake disc. The actuating device is provided on the inside of the brake disc, and the brake liner on the outside is attached to the caliper body.

When the driver performs braking, under the action of liquid pressure, the piston in the brake wheel cylinder and the brake block on it move to the left and press on the brake disc, so the brake disc gives the piston a reaction force to the right, making the piston and the brake caliper move to the right along the guide pin axis until the brake block on the outside of the brake disc is also pressed on the brake disc. At this time, the brake blocks on both sides of the brake disc are pressed against the brake disc, clamping the rotating brake disc to produce braking.

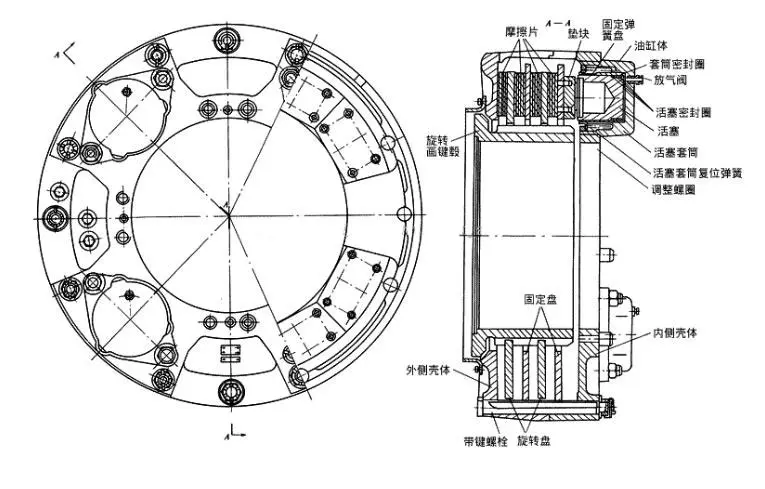

Two, the overall type

The fixed and rotating components of the friction pair of the whole brake are disc-shaped, respectively called the fixed disc and the rotating disc, and all the working faces can be frictionally contacted at the same time during the braking process, and the structure principle is similar to that of the friction clutch.

Because this brake replaces the original brake liner with a disc, the friction area during braking is large, so the braking force is relatively large, and it is more suitable for heavy duty vehicles. Relatively, the friction contact area is large, which also leads to a large amount of heat energy generated during the braking process and is not easy to discharge, which is easy to cause the brake disc to be heated and deformed under continuous braking for a long time, affecting driving safety, and the service life of the friction sheet will also be affected, and it needs to be replaced frequently.