Can the trailer continue to drive if the rear axle is broken?

The trailer rear axle generally refers to the trailer axle installed on the semi-trailer. It is connected to the frame through the suspension, and the wheels are installed at both ends without driving and steering functions. action.

Some car owners believe that compared with the steering axle and drive axle, the function of the rear axle of the trailer is relatively single, the structure is relatively simple, more durable, and more resistant to construction, so it is still used after the rear axle fails. It's not right.

Although the structure of the rear axle of the trailer is relatively simple, it is mainly composed of axle body assembly, brake assembly, wheel end assembly, etc. There are still many large and small parts that can be subdivided, and the number of parts is as high as nearly a hundred. What can be seen from the outside, such as brake drums, hubs, dust covers, bolts, camshafts, supports, circlips, etc., can not be seen from the inside, such as bearings, brake pads, bushings, retaining rings, fixed pins, oil seals etc.

These parts are sophisticated and interlocking with each other. Any problem with any of them will affect the performance of the trailer axle. Tires, broken axles, brake failure, chassis loss of support, vehicle out of control and other problems seriously affect driving safety.

Therefore, car owners must pay special attention to the performance of the vehicle during daily use of the car. Once there are abnormal noises during driving, hot shafts, oil leakage, body shaking, unstable high-speed driving, and braking deviation, etc. If there is a problem, it should be repaired in time or drive the vehicle directly to the maintenance point.

In addition, it is also very important to do a good job in daily rear axle maintenance. If it is a conventional trailer axle, the wheel end system must be maintained once every 50,000 kilometers the trailer travels.

1. Remove the wheel hub, clean the bearings, journals, and hub cavity, and scrape off the old lubricating grease. You can clean and wipe it with detergent or diesel oil, then clean it with clean water, and finally dry the inner cavity of the hub with a clean rag;

2. Check the hub, bearing, bearing race and other parts to see if there are cracks, looseness, loose rollers and other problems, and replace them in time if they exist;

3. Check the matching gap between the inner diameter of the bearing and the shaft diameter, measure the upper and lower points where the shaft diameter is perpendicular to the ground (here is the maximum wear position), the gap should be ≤0.1mm, if it does not meet the requirements, replace the bearing in time;

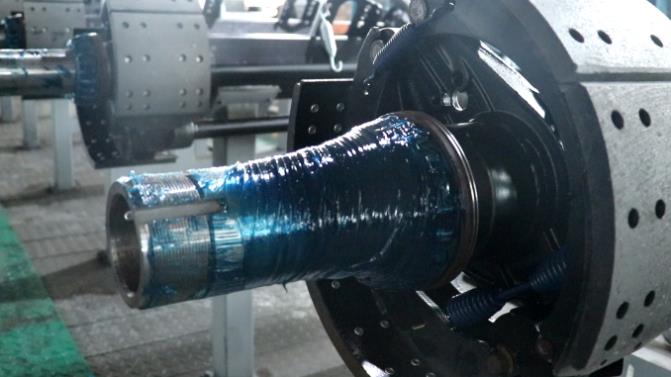

4. If the hubs and bearings meet the requirements, add new grease between the inner race of the bearing and the rollers. Be careful not to overdo it, just a thin layer, otherwise it will easily affect heat dissipation and braking;

5. Reinstall the hub.

If the owner uses a maintenance-free rear axle, the maintenance cycle can be extended accordingly, generally reaching 50W or 80W kilometers, but daily inspection and maintenance are still essential, especially for heavy-duty vehicles or vehicles that often run on bad road conditions , and its maintenance cycle should be shortened accordingly.

1. During use, the car owner regularly checks through the transparent baffle at the shaft end whether the internal lubricating oil is above the normal level and whether there is discoloration;

2. Every 12 months or 100,000 kilometers, use a magnet probe to check whether there are impurities in the lubricating oil through the oil injection hole;

3. Regularly check the hub fasteners to see if there is looseness or oil leakage, and check whether there is any abnormal sound on the rear axle or whether the bearing is shaking;

4. Regularly add or replace lubricating oil as required.

Of course, whether the quality of the rear axle itself is qualified also has a key impact on the subsequent use.

For example, in the selection of raw materials, high-strength alloy steel is generally used. If the manufacturer chooses unqualified steel for cheap, the foundation will not be well laid, and subsequent processing will be meaningless;

Another example is the structural design. The main function of the rear axle is to bear the load. If the load cannot be distributed reasonably in the structure, excessive stress concentration will easily occur in subsequent use. Therefore, the design of the rear axle needs to be strictly professional;

The production process and processing technology are also critical. If the treatment is not up to standard, the performance of the steel will not be fully improved and brought into play. If the process is not up to standard, it will easily lead to defects such as trachoma and shrinkage cavity, which will affect the strength, toughness or precision of the finished product.

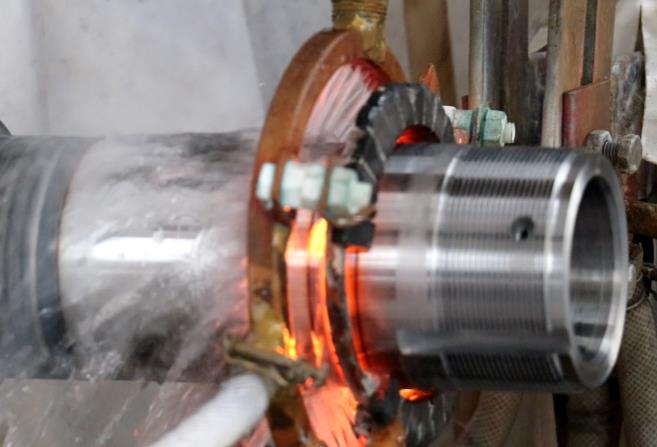

Here I would like to remind all car owners that if the rear axle pole is broken, it is best not to weld it and continue to use it. The broken axle can be reused. It looks like it has been restored on the outside, but the damaged structure inside cannot be completely repaired. Instead of spending money to repair an axle that may have problems in the future, it is better to directly buy an optical axle blank or a semi-finished axle to replace it. The American and German axles produced by DARO Group are affordable, reliable in performance, and worry-free.