Are plastic leaf springs reliable for pulling goods?

Vehicle lightweight is one of the more popular keywords in the automotive industry in recent years. It not only helps energy saving and emission reduction, conforms to the general trend of environmental protection, but also brings many benefits to car owners, such as more loading capacity , less fuel consumption, better handling and higher comfort, etc.

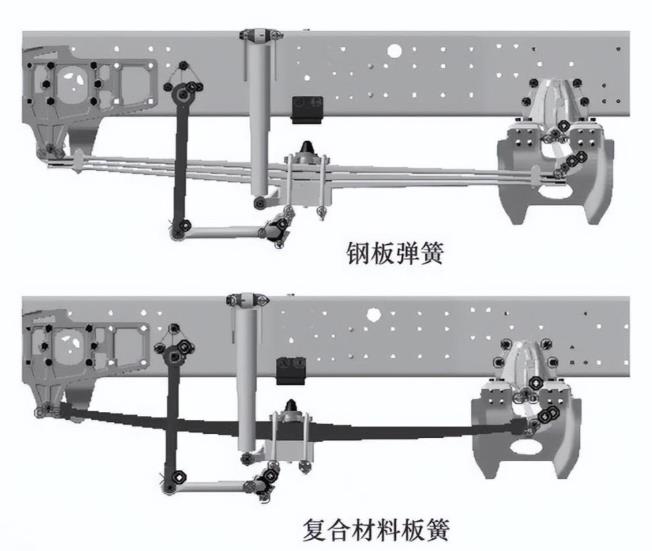

In order to pursue light weight, the industry can be said to have racked their brains. From the body, girders, tops, to trailer axles, tires, leaf springs, etc., they are all studying how to obtain lighter weight, so plastic leaf springs appeared.

According to relevant data, the total weight of the leaf spring made of plastic (including metal joints) is about 50% of that of the leaf spring, which can greatly reduce the weight of the vehicle.

It can be light or light, but what about the load-bearing geometry? When many car owners see such a leaf spring, their hearts are pounding: Can it bear a load of several tons, tens of tons or even dozens of tons? Can it be used for a year if it encounters a bad road?

Plastic leaf springs have obvious advantages

In fact, although this kind of leaf spring is plastic in nature, it is not plastic in the traditional sense. It is a composite material. The official name is "polyurethane matrix resin glass fiber reinforced leaf spring", which is made of reinforced composite fiber. It is synthesized together with the resin matrix through a certain process.

It may be rather obscure to say so, let’s make an analogy: such as cement boards used in building materials, composite fibers are like steel bars in cement boards, providing strength and certain tensile properties, and the resin matrix is equivalent to cement , while protecting the steel bars, it can also make the cement board stronger, and it is not a big problem to meet the general transportation.

In addition, plastic leaf springs are not new products. They have been widely used in the field of passenger vehicles such as cars and SUVs. Some foreign light trucks, heavy trucks, buses and trailers that pursue lightweight are also used.

In addition to the self-weight advantages mentioned above, it also has the advantages of good shock absorption effect, high stress intensity coefficient, strong fatigue resistance, and long service life, which can greatly reduce the comprehensive vehicle cost of users.

Can plastic leaf springs replace steel plates?

It can be said that the development prospects of plastic leaf springs are still relatively broad, but it may be a long way to go to get large-scale application in domestic commercial vehicles. "Rare things are more expensive" is an eternal truth. In the current environment where freight rates continue to decline, the high price alone may be able to dissuade many car owners. Besides, plastic leaf springs are not only high in upfront cost, but also in subsequent maintenance and replacement. Whether it is parts or technology, they are still relatively scarce in the current market.

In terms of strength, although plastic leaf springs do play a unique role in some standard-load transportation conditions that are sensitive to the vehicle's own weight, they can be used in the field of heavy-duty transportation, especially in the face of complex domestic transportation conditions. Whether the leaf spring can maintain the same load-bearing capacity as the leaf spring when the weight is reduced by more than half, or maintain the same excellent performance as the experimental data, is probably unknown.

If the car owner chooses a plastic leaf spring, remember not to overload it during use. Once the weight limit of the leaf spring thickness and fiber layers is exceeded, it is still very dangerous. After all, leaf spring breakage is not a trivial matter. As for heavy-duty vehicles, when choosing a suspension, it is still necessary to consider the actual situation comprehensively. After all, the choice of any component must be based on safety, and the most important thing is reliable strength.