Air suspension bag common failure and solution

Air suspension came into being in the middle of the 19th century. It went through many stages, such as air spring, air bag composite suspension, semi-active air suspension, central inflatable suspension, etc., and was not applied to trucks, buses, cars and railway cars until the 1950s.

What are the main advantages of air suspension over other types of suspension?

1. Light weight. Compared with leaf spring, the biggest advantage of air suspension is light weight, in the weight advantage is obvious.

2. Can be raised or lowered. Can be lifted in two aspects, one is through the air suspension can be lifted, reduce wear, save fuel, especially suitable for one-way empty car situation. Second, through the manual height valve in the air suspension system, the height of the vehicle loading platform can be adjusted within a certain range, convenient loading and unloading of goods.

3. Smooth running, good shock absorption performance. Vehicles with air suspension ride more smoothly than lightweight vehicles. The height of the air spring can automatically adjust according to the road condition, reduce the vibration, is conducive to the protection of cargo safety.

The most common fault of air suspension is that the air bag is wrinkled or the air bag is less or no air. The reasons for these two cases are not the same, and the treatment methods are not the same.

1. Air bag folds.

Reasons:

(1) When the vehicle is transferred and hoisted, the airbag is stretched out more and is not restored normally, leading to the airbag wrinkling;

(2) When vehicles enter and leave the maintenance workshop or a large slope, individual airbags may also be overstretched, resulting in airbag wrinkles.

Treatment method:

Disassemble the rubber connector under the horizontal height valve, lift the rod upward, wait for all the air bags to be full of gas, and then install the rod back, the air bag can return to normal state.

In addition, in the process of driving such a failure often occurs, it is necessary to consider increasing the limit device between the trailer axle and the frame.

2. The airbag has little or no air.

Reasons:

(1) Air suspension special air reservoir no air or low pressure, when the trailer pressure is less than 6 kg, the pressure protection valve will suspend the air supply to the air suspension air reservoir, to ensure that the brake system to maintain sufficient pressure;

(2) The air pipeline is blocked or discounted, but not gas;

(3) The valve connection rod falls off at the horizontal height;

(4) The horizontal height valve is damaged.

Treatment method:

The air source of the air suspension is connected by the brake system, and stored in the special air reservoir through the pressure protection valve. Work through the filter to the horizontal height valve of the air suspension, and then to the left and right air bags. When the air bag is less or no air, as long as you find the right cause of failure, you will know where to start, and it is not difficult to solve.

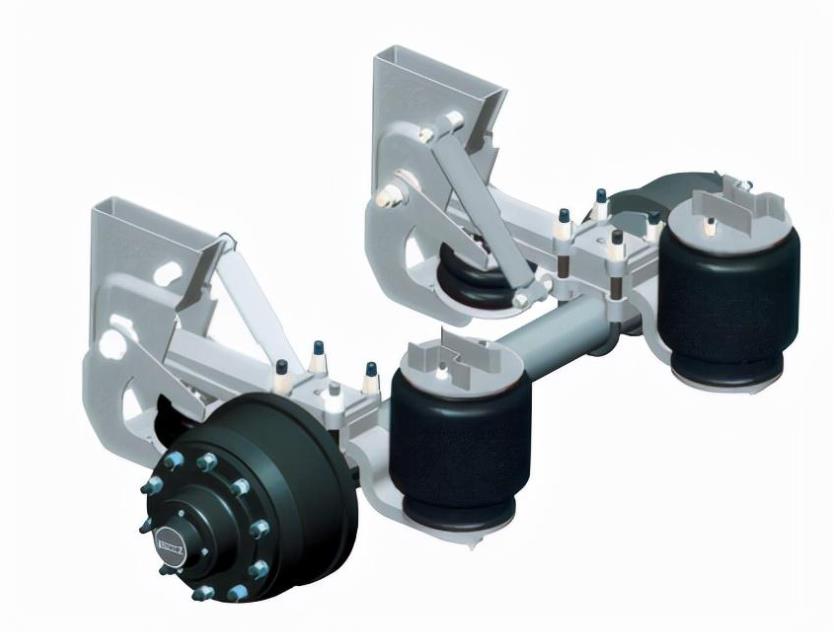

GB7258-2017 motor vehicle operation safety technical conditions after the implementation of the national standard, the requirements of the three-axle plate, warehouse grid type semi-trailer must be equipped with disc brakes and air bag suspension, so that the use of air suspension is more and more widely. DARO's air suspension series is forged using 3D molding technology for greater toughness and tightness, which can filter the impact of bumps on the frame and greatly reduce the load and stress. With DARO disc axle, you can ensure driving safety, reduce or avoid cargo loss, improve operational efficiency, and increase economic benefits.