Strict quality control to create high-quality trailer axles

Product quality is the basis for the survival of enterprises, especially for trailer axle enterprises. Only the quality of the axle meets the standard, in order to provide customers with safe and reliable use of security, in order to win the market widely recognized.

In DARO Group, the first corporate value is quality first. More than 20 years after entering the market, DARO has always adhered to the strict and persistent attitude of quality control, the quality test to the raw material link, and built a set of perfect quality control system, on the basis of industry standards to establish more stringent technical standards and quality control system.

1.

Rigor + standard

Eliminate possible quality problems in the production process

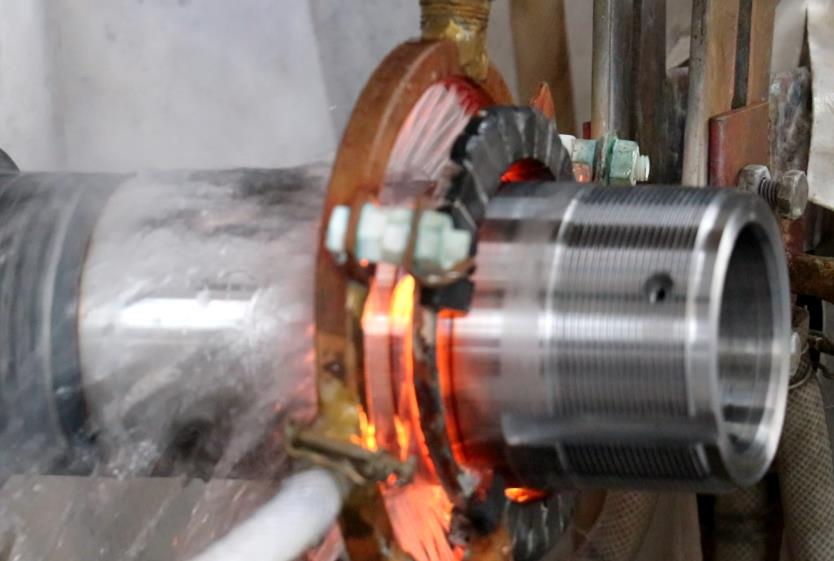

Ensure product quality, production process is the top priority. In DARO trailer axle, each axle has to go through more than a dozen processing processes, including thermal conditioning, shot blasting, multi-point alignment, shaft head finishing, medium frequency induction strengthening, primer + top paint, machine popularity welding protection, automatic assembly, production accuracy strictly in line with JTT475-2020 trailer axle product implementation standards.

At the same time, DARO has established strict process inspection regulations, and all positions must strictly abide by the operating instructions, so as to avoid quality defects caused by non-standard operations. From incoming material testing, manufacturing process testing, semi-finished product testing, finished product testing, warehousing testing, delivery testing, only all qualified inspection, to meet the acceptance standards, in order to successfully put into use.

2.

Precision + Specialty

To provide a strong guarantee for quality inspection

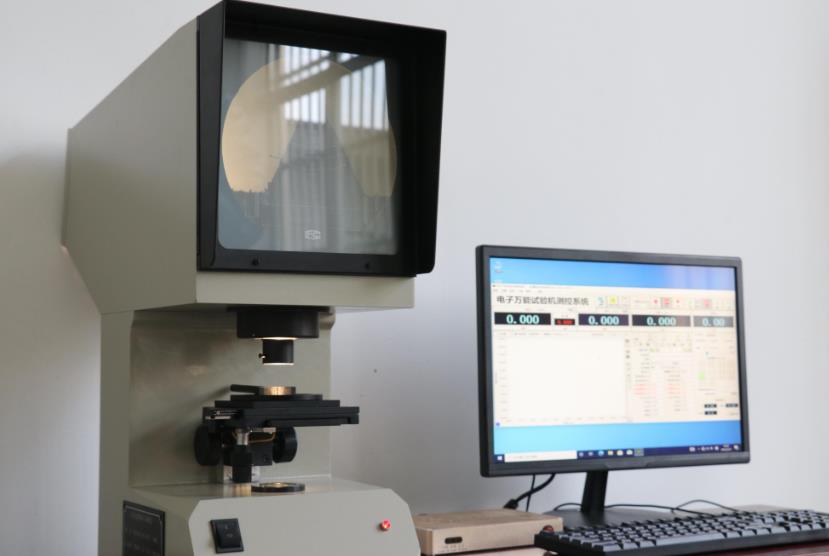

Quality inspection is the supervision of production quality, and it is also a test for testing instruments. In order to do a good job in the verification of axle quality details, it is necessary to be equipped with high-precision, authoritative and reliable instruments.

To this end, DARO trailer axle has set up an experienced quality inspection team, and invested in automatic and intelligent testing equipment such as spectral detector, metallographic microscope, universal tensile testing machine, fatigue testing platform, impact testing machine, Rockwell hardness tester, magnetic particle testing machine, salt spray testing machine, forming a complete performance testing and evaluation mechanism for raw materials, semi-finished products and finished products.

At the same time, DARO strives to increase the number of professional quality inspection personnel, strengthen and improve its own inspection level, to provide a strong guarantee for accurate and efficient inspection of product quality, and fully ensure that every product delivered by the factory is a qualified product that has passed rigorous inspection.

There is a saying in the industry that goes like this: the head of Shaanxi, the hanging of Shandong, the trailer axle of Liangshan run the world. As one of the earliest axle enterprises established in Liangshan, DARO Group has been focusing on the research and development and manufacturing of high-quality trailer axle. DARO firmly believes that one more inspection process is equal to one more layer of security, which can make customers more secure and less trouble in the subsequent use. In the future, DARO will continue to deepen its efforts in the field of semi-trailer accessories, providing customers with affordable, practical and practical products and services.