Product recommendations | DARO disc axle of trailer

As far as the most approved trailer axle on the market goes, disc axle goes. Since the introduction and implementation of the GB7258-2017 National Standard for Vehicle Operation Safety Technical conditions, the three-axle axle and the grille semi-axle have been required to install disc axle axle and air suspension, which, coupled with the gradual prevalence of the lightweight trend in the trailer industry, makes more and more owners turn their attention to Disc Axle.

Disc trailer axle is not a new product, but it has been applied more to passenger vehicles in the past. Compared with drum axle, the major features of disc axle are light weight, fast heat dissipation, sensitive response, strong thermal attenuation and water attenuation ability.

Correspondingly, the disc axle braking friction area decreases, the braking force is weaker than drum axle, the heating speed is faster than drum axle, and the disc axle can not be cooled by water. Because of these reasons, many car owners have questioned the promotion of disc axle.

· disc axle questions are common

1, disc trailer axle brake small brake car?

Although the disc axle braking strength is weaker than the drum brake bridge, but for the compliance of the use of ordinary standard load transport vehicles, such as three axis plate or grid, its braking strength is quite enough, of course, overload or speeding case is another matter.

In addition, although the disc axle braking force is small, but its braking response speed is incomparable to the drum brake bridge, the owner of the brake can push the caliper brake almost immediately, can provide braking force output in a more timely manner.

For trailers that need to transport heavy goods, or trailers that often run mountain roads, they can be used together with hydraulic retarder and other auxiliary braking devices. On the one hand, liquid retarding can make up for the shortage of brake force of the disc brake bridge. On the other hand, the response speed of the disc brake bridge can maximize the function of liquid retarding to the extreme. In this way, we can realize the super combination of fast braking response speed, strong braking force and more stable and reliable braking.

If ABS and EBS systems are installed on this basis, the trailer can stop smoothly in the shortest distance, which is much better than the drum axle.

2. Is the disc axle heating up too fast?

Although there is no doubt that the temperature rises fast in the continuous braking of disc axle, we should not forget that the brake disc and friction plate of disc brake bridge are directly exposed in the air, and the heat dissipation speed is very fast, especially in the process of vehicle driving, the rapid flow of air can make the disc brake bridge get faster heat dissipation speed, because there will not be overheating.

Moreover, the thermal attenuation performance of the disc brake bridge is higher than that of the drum axle. According to the experimental data comparison, the friction plate temperature of the drum brake reaches more than 300 degrees, the friction coefficient will decrease by 40%-50%; When the temperature of the disc brake friction plate rises from 100 degrees to 400 degrees, the friction coefficient hardly changes, and the braking force output is relatively stable.

3. Disk axle is easy to be damaged by water

Disc axle in the absence of an auxiliary device, if you encounter a long downhill need a long time continuous braking situation, especially when the vehicle load is relatively large, the brake disc and friction plate temperature is very obvious, if the brake disc is red with cold water directly on, the temperature drops several hundred degrees instantly, it is easy to lead to the destruction of the brake disc. So some owners worry: rainy day disc brake bridge is not very easy to break?

Compared with a large amount of cold water concentrated on the red brake disc at the moment, the rain is continuous, uniform and non-concentrated on the axle, so it will not lead to the destruction of the brake disc.

In addition, after the trailer wading, the disc brake through one or two braking, the performance can be immediately restored, but the drum brake to be recovered after a dozen consecutive braking. From this point of view, the resistance to water attenuation performance, disc axle is better than drum axle.

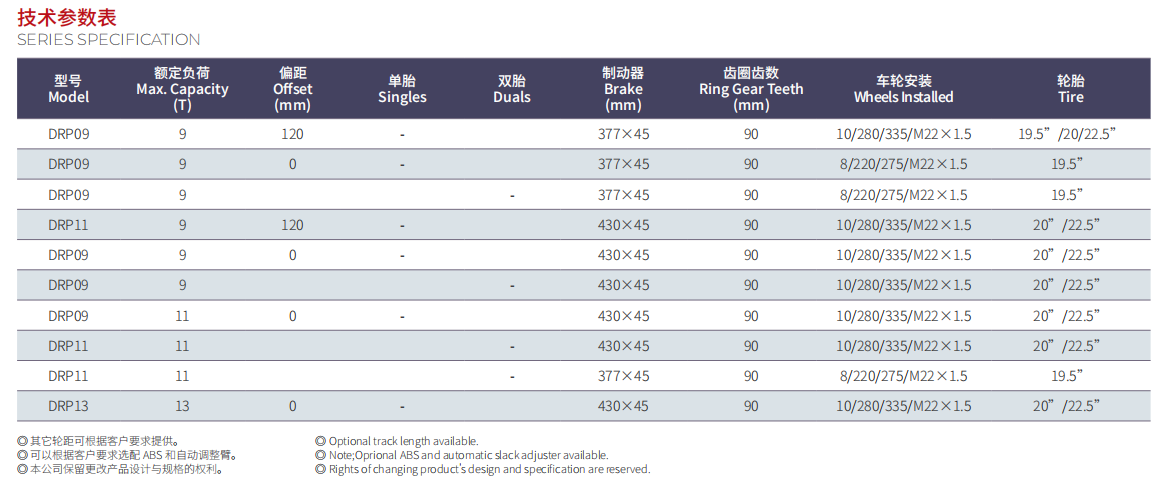

·DARO disc axle specifications

·DARO disc trailer axle advantage

1. Better raw materials

DARO trailer axle adopts 20Mn2 high-strength alloy seamless steel pipe with 10-11mm wall thickness. Compared with ordinary steel pipe, it has better tensile strength, yield strength, impact toughness and other properties, and it is not easy to crack during processing and use.

2. The whole process of production is controllable

Has its own factory, the whole production process is subject to unified, strict quality control, 15 production processes, from the internal mechanical properties of steel to the external dimensional accuracy, fully in line with the national standard requirements.

3. Strict quality control procedures

The quality inspection process starts from raw materials and covers every link of design, production and testing. At the same time, quality inspection workshops are set up, such as fatigue test, salt spray test and magnetic particle detection test of shaft body. High-precision instruments are equipped to accurately test the stress limit of axles, so as to ensure that fatigue failure does not occur during the service period.

4, accessories selection

DARO trailer axle accessories brand has been in the industry for many years, the quality has passed the baptism and test of the market, with the corresponding quality assurance ability. In addition, DARO has to go through a series of quality control procedures before it can be used, which is equivalent to an extra layer of quality assurance.

5. After-sales quality assurance

Axle is a consumption part of the vehicle, if there is no special after-sales, the follow-up maintenance is very difficult. All the axles, axles and accessories delivered by DARO Group are equipped with warranty service commitment letters, and a special after-sales team is set up to track users' usage and help customers solve product-related problems. DARO axle entered the market for 20 years, cooperative customers all over the world, always maintain zero quality disputes.

6. Customized production

In order to meet customers' different requirements in the field of axle tonnage, wheel pitch, parameters and other requirements, DARO launched the axle customization service, according to the actual use of customers to design drawings, then customized production, such as hub, brake drum, bearings and other parts can also provide a variety of options.

·DARO axle application field of disc trailer

1, three axis fence plate/warehouse grid car: these two types of trailer is GB7258-2017 motor vehicle operation safety technical conditions of the national standard explicitly stipulated, must be installed disc axle models, in line with will affect the license or road driving.

2. Precision instruments/valuables transport vehicle: The particularity of this kind of goods has strict requirements on vehicles and transportation process. Disc axle brake sensitive and more stable, can avoid the transport of goods in the process of bump or large vibration.

3. Dangerous goods transport vehicle: the dangerous chemical transport vehicle has a higher risk factor than ordinary goods vehicles. The use of disc axle can reduce accidents caused by the uneven distribution of braking force and slow heat dissipation of brake as much as possible.

4. Mountain road transportation: compared with ordinary freight routes, the road condition of mountain road transportation is worse, and the requirements of the braking system are very high. Disc axle, such as hydraulic retarder and ABS/EBS system, can not only make the vehicle stop smoothly in a shorter distance, to achieve the best braking effect, but also can prolong the service life of the friction plate, reduce tire loss, at the same time can reduce the weight of the vehicle, fully energy saving, saving comprehensive vehicle cost.