Independently innovating and manufacturing high-quality axles

Axle is one of the essential parts of semi trailer. With the continuous improvement of the development level of the logistics industry, the trailer axle products and technologies on the market are constantly updated and iterated. In the face of increasingly fierce competition in the axle industry, it is undoubtedly the pursuit of most enterprises to create independent innovative enterprises, establish product technology advantages, adhere to science and technology self-reliance and self-improvement.

This is also the development path that DARO Heavy Industry Group has been adhering to since its establishment 20 years ago.

"Our goal is to build high-quality axles, establish a world-class brand of commercial vehicle axles, and be the stick and innovator of Chinese machinery manufacturing industry." -- Du Cunxin, head of design at DARO.

Build brand strength steadily

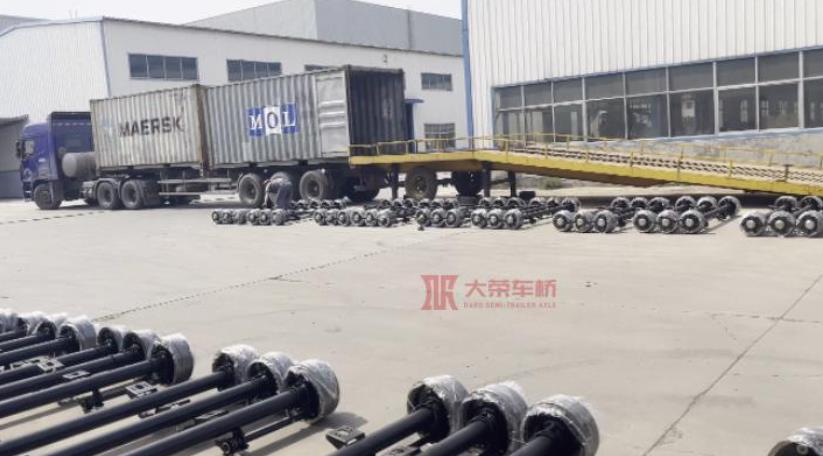

DARO Heavy Industry Group was founded in 2001, is a collection of "research and development, design, production, sales, service" in one of the global axle research and development manufacturer, with its own brands "DARO", "RSCC", products cover American and German two major series.

In the interview, Director Du mentioned many times, "We are a factory, and the product is the soul of the factory. We will try our best to make the product good, make the higher cost performance, and let the users get higher product value. This is the direction we will go." That's what DARO started out with, and that's what DARO stuck to.

After more than 20 years of precipitation and accumulation, DARO has established a sound R&D system, set up an independent R&D department, equipped with a number of senior professional titles, doctoral and various technical talents, professional related to machinery manufacturing, mechanical mechanics, etc., average age of 35, is an experienced, high-quality, high-level R&D team. The company has passed the quality, environment, occupational health three management system certification, at the same time organized and carried out 43 research and development projects, completed the transformation of new products, new technology, new equipment and other scientific and technological achievements 25, has 14 national invention patents including utility models, has been highly recognized in the industry.

What DARO is achieving today didn't happen overnight. According to Du, DARO started the research and development of the "all-in-one axle tube" production equipment in 2004. At that time, the trailer axle industry was highly polarized and the core technology was concentrated in the hands of foreign and leading companies. It was impossible to get relevant guidance or reference. At that time, DARO did not have a special research and development center, but only a few technical personnel. They gathered together to think and discuss day and night, and revised the drawings bit by bit, and then tried again according to the drawings, and revised and tried again and again. Finally, after consuming more than 100 tons of test waste, they developed the "integrated shaft tube" mass production equipment.

Although DARO's "integrated shaft tube" mass production machine started late compared with the international first-tier brands, the shaft tube produced by DARO is not only comparable to foreign products in quality, but also closer to the use needs of domestic users. Once it came out, it won the attention of the market. Some customers even rushed to Liangshan one month in advance to order in order to grab the trailer axle of Daro. And the spirit of Darong people, who face difficulties head-on, not impatient, down-to-earth, has taken root and continued since then.

R&d and innovation to expand new product areas

Under the influence of the epidemic, many industries are facing a huge impact, so is the axle industry. However, DARO has been proactive in its response, maintaining its R&D schedule through the years of pandemic cycles.

"In today's environment, it is critical for companies to expand into new product areas and open up new room for growth. Simply put, we do what is missing and what is needed in the market." Director Du said. Market driven reverse research and development, capture market demand, combined with the application characteristics of axles, develop personalized products.

In recent years, DARO has seen an increase in the number of customers contacting Daro about trailer Bridges, such as flatbed trailers, farm trailers, industrial trailers, motor homes, and more. Unlike semi-trailers, these vehicles are often used in different areas and specific functions, so there are various requirements for axles.

"In the current trailer axle market, or to standard type axle mainly, tonnage or wheel pitch are relatively concentrated, manufacturers are easy to produce, users are convenient to buy." Du director said, "In contrast, the light trailer is not the same, the application field is more extensive, the same application field can be divided into a lot of functions, such as agricultural trailer, pull harvester, grain, grass, fertilizer, function is all over the place, their tonnage, wheel pitch is generally not the same, can meet the use of axle can only go customized way."

Drawing is the key to the customization of axles, which is the guidance and specification for the production and processing of axles. Its accuracy directly affects the processing accuracy of each subsequent production process. After customer requirements are submitted, DARO R & D center will first hold a meeting to discuss and analyze, determine product structure, specification parameters, parts collocation, process data, material properties, machining accuracy requirements, etc., design the corresponding product drawings, and improve the machining drawings and machine and equipment debugging schemes of each production and quality control process on this basis. Lay a good foundation for the implementation of subsequent production and processing. The production technology and experience accumulated by DARO Group over the years has provided the feasibility guarantee for the processing of customized axles.

"Our goal with the launch of customized trailer axles is to give every DARO customer access to an axle that perfectly matches their vehicle. In addition to custom production, we also launched a full set of axle solutions, mainly for some customers who have not contacted this field before, such as accessories do not know how to match, at this time you can directly choose from our program, can be more worry, more effort."

Since DARO customized trailer axle entered the market, it has helped many trailer users solve the problem of difficult to buy. More and more customers come to Darong for "private customized", most of which come from Inner Mongolia, Xinjiang, Northeast China, Russia, Australia, Europe and Southeast Asia and other regions. Most of the demands are for small-tonnage, lengthening, high-bearing, high-fitting and other special purpose axles. Multiple buybacks are common.

Throughout the development of the market, changes are the norm, only continuous innovation, improve the ability of independent research and development, in order to remain invincible. DARO Group takes innovation as its core value, aiming to continuously provide new technologies, new processes and new products to the market and create better products and services for customers through independent innovation. "In fact, the essence of innovation is to make every product, and that's what DARO started out with."