DARO builds international high-end trailer axles

With the continuous improvement of vehicle production technology, there are more and more large and small axle brands in the market. Can say which brand qualification old, cost-effective and high, DARO trailer axle is definitely among the best. Especially in many old driver's car, printed "RSCCZ" logo axle is not rare.

The product categories are rich to meet the different needs of users

DARO Heavy Industry Group, formerly known as DARO Traffic Machinery Co., LTD., was founded in 2001 and has a history of 20 years. DARO trailer axle categories are numerous, mainly American and German two major series, but also involving air suspension, single point suspension, bearing, hub and other trailer accessories.

Currently, DARO's most popular type of axle is the American 13t standard drum axle. This kind of axle has relatively low price and common parts in the industry. It has the characteristics of strong bearing capacity and convenient maintenance, etc., and has a very high application rate on semi-trailer. In addition to the standard model, the axles also extend to 10t lightweight, 13t widened, 16t, 20t, 25t and maintenance-free styles, which can meet different transportation conditions.

Under the promotion of related policies, the popularity of disc brake is also improving. DARO disc axle entered the market in 2018, the use of all-in-one alloy brake disc, the heat conduction rate is better than ordinary materials, after thermal conditioning treatment, more durable wear resistance, higher heat capacity, not prone to overheating in use.

The quality of the axle is closely related to the parts. DARO trailer axle bearings choose P6 high grade bearings, with high precision, high load, low rolling resistance characteristics, less friction resistance, longer service time; The brake pad is a special trailer type of high fixed products, high temperature recession is small, more stable braking; The hub adopts low-pressure casting lightweight material, which performs well in tensile strength, yield strength and high-speed balance, and can cope with various complex road conditions.

Multiple processes escort product safety

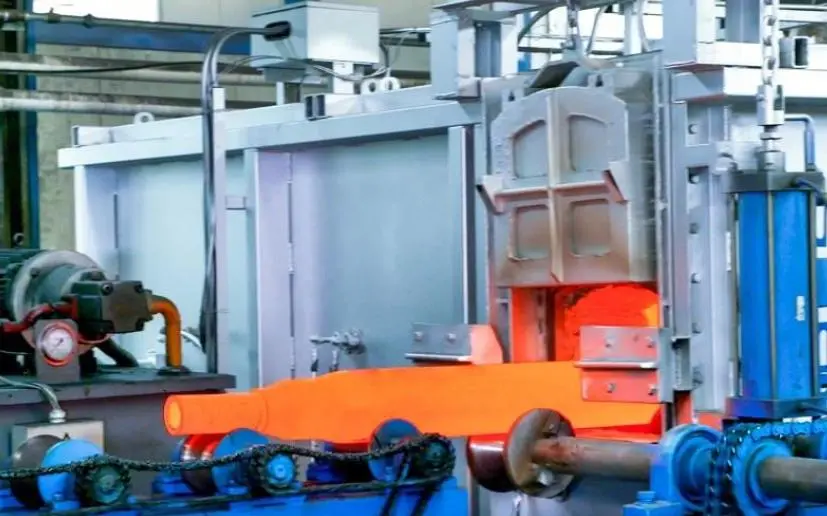

As a kind of medium and heavy freight vehicle, the transport condition of semi-trailer is more complex than that of ordinary vehicles, so the quality requirements of axle are more strict. In addition to the control of raw materials and components mentioned above, the production process is also crucial. DARO axles are equipped with more than ten processes in the production process, such as hot spinning rolling, cold pushing, automatic quenching and tempering, sand blasting and straightening. Today we are going to look at four major processes that are related to load-bearing performance.

"One piece" heat treatment molding: the axle is stronger, more durable and more resistant to heavy load.

The so-called "one-piece" heat treatment molding refers to the heat treatment technology to create the shaft body and shaft head from a seamless steel pipe, the shaft head and shaft beam integrated, there is no need to weld the shaft head to the shaft beam as the traditional "three-piece" axle.

In this way, there is no trace of artificial connection between the axle head and the axle beam, which fully avoids welding deformation and has a stronger ability to resist heavy load.

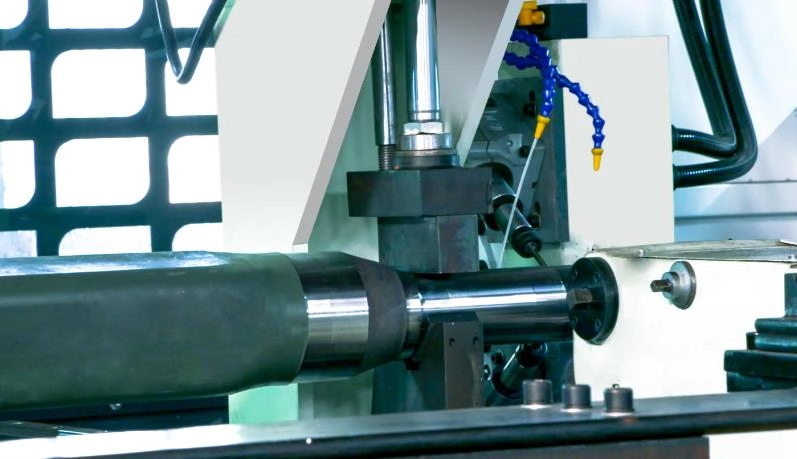

CNC machine finishing: ensure axle accuracy and parameters.

The number of components of the axle is as high as 100, which belongs to the veritable precision machinery. If the accuracy is not up to standard, when bearing the variable load of the vehicle in use, it is easy to form a small crack in the high stress area, and eventually lead to axle fracture, affecting the safety.

Axle finishing is like laying a foundation for a tall building. Only by mastering the accuracy, parameters and size can the axle be produced more firmly and more durable.

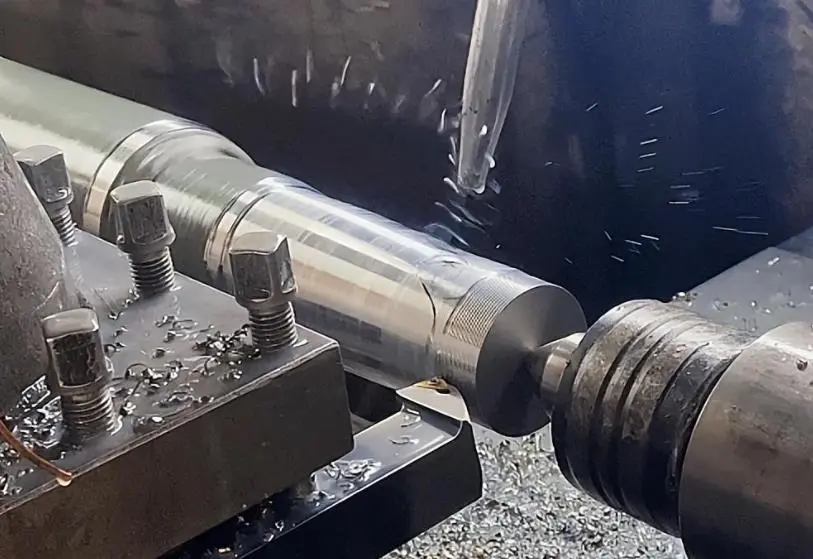

Medium frequency induction strengthening treatment: to ensure the stability of the performance of the axle under high speed.

Mainly for the key part of the shaft head and bearing connection, adding intermediate frequency quenching treatment, further improve its strength, toughness and other properties, to ensure that the axle in use, especially under high-speed operation, to ensure stable performance output.

Millions of fatigue tests: ensure that the fatigue performance of shaft body meets the standard.

After the DARO axle is formed, it needs to go through fatigue test to fully simulate the bearing condition of the axle. Generally, it needs to test 12 days, about one million times, mainly to test whether the fatigue performance of the axle can meet the standard requirements. After reaching the standard, it can enter the final assembly link.

Besides reliable quality, another reason DARO axles are popular with car owners is their high cost performance. The good axles on the market are too expensive and the cheap ones don't work well. The DARO axles are in a league of their own. Since entering the market for 20 years, DARO has never relied on the quality of the price, always adhere to the most reasonable price to reward new and old customers, "real life, honest work", with many trailer factories, logistics companies, transport teams and retail investors to establish a good and stable cooperative relationship.