Daro Axle: casting great quality escort safety mission

In China's commercial vehicle production and manufacturing landscape, there are mainly four commercial vehicle bases: Suizhou in Hubei Province, Longyan in Fujian Province, Liangshan in Shandong Province and Tieling in Liaoning Province. They are divided into four bases with equal momentum, which can be referred to as the industry leader. Daro Heavy Industry Group is the representative of Shandong Liangshan trailer axle enterprises.

In 2001, Daro Heavy Industry Group was established in Liangshan, then known as Daro Traffic Machinery Co., LTD., which was the first trailer axle enterprise in Quanpu Industrial Park. Now twenty years have passed, and there are more than 200 local factories, large and small. However, when foreign businessmen arrive in Liangshan, they still like to go straight to Daro Group, and Daro is still the first object favored by users.

So, what is unique about this vehicle bridge enterprise? Today, let's decode the secret of Daiong's enduring popularity in the ever-changing market.

Independent innovation helps enterprises take off

Daro Heavy Industry Group is located in Quanpu town orchard Road, a total area of about 60,000 square meters, including plant area of about 32,000 square meters, such a scale and standard in Liangshan is second to none. It is understood that since its establishment, the workshop production line has been upgraded and innovated for six times. At present, it adopts the domestic advanced intelligent production line, which realizes the automation from manufacturing to assembly and product testing, with a total investment of nearly 1.5 billion yuan.

In order to produce good products, the hardware conditions should meet the standards and the soft power should keep up. In order to gain a firm foothold in the market, enterprises must keep up with the pace of The Times, which requires enterprises to have a certain ability of independent innovation. Daiong Group around the "independent innovation" and "self-reliance" this line, in product design, product development and production technology on a lot of efforts.

Du, director of the research and development department, said that Daro Group had faced many technical difficulties at the beginning of its establishment. At that time, the axle of domestic production was still three-joint type, and some leading enterprises produced integrated trailer axle tubes with the help of foreign technicians, but they built high technical barriers to occupy the market. At that time, Daro Group did not have a special research and development department, so the chairman of the board personally led the technical staff of the workshop to carry out the research on the all-in-one trailer axle production technology without any guidance, reference and technology reference. After repeated experiments and modifications, the difficult problem was finally solved after nearly two years of efforts and nearly 200 tons of waste materials were tested. Also fully consider the use needs of domestic users in the design of the optimization and improvement.

At present, the R&D team of Daro has reached 30 people, including doctor's degree, master's degree and overseas returnees. There are also many members with senior titles who have been engaged in trailer axle and axle design and research and development for many years. They are rich in relevant experience.

Director Du said that the axle is an important part of the trailer chassis, for the trailer driving, load-bearing, braking and other safety performance plays a vital role, therefore, the design and development of the axle more need to be rigorous and careful, the slightest careless. When flaws are found in an experiment, overtime is not uncommon. "In '17, we designed a new product, but when we tested it, we found some deviations from the predicted values. It took us nearly a month to design that product. When we saw it, we were all unhappy, and we didn't enjoy eating or sleeping. It took a couple of all-nighters to figure out what the problem was and fix it, and we felt really good at that moment."

Daorong people know that being ahead of others is not worth being proud of. Being ahead of oneself is a skill. Inspired by this spirit, Daro Group continues to deepen its efforts on the road of continuous independent innovation, and has developed and manufactured a series of products such as disc axle, German trailer axle, American trailer axle, concave axle, special axle, three-line six-axle axle, etc., which not only meet the needs of users, but also realize its own development and take-off.

Exacting standards lead to reliable quality

Guided by the workshop director, we visited the production workshop of Daiong Group.

Ren director introduced that although the number of automobile bridge enterprises is increasing, but the real production enterprises still account for a minority. On the one hand, it is expensive to build a set of refined, standardized plant, and now the axle industry has entered a period of rapid development, if you do not have the core advantages, it is easy to be left behind by the industry. Some manufacturers are afraid to take such risks, so they choose to take semi-finished products from big factories, assemble them themselves and sell them to the market. Although this can get a share of the axle industry, but dependent on others ultimately can not make their own brand.

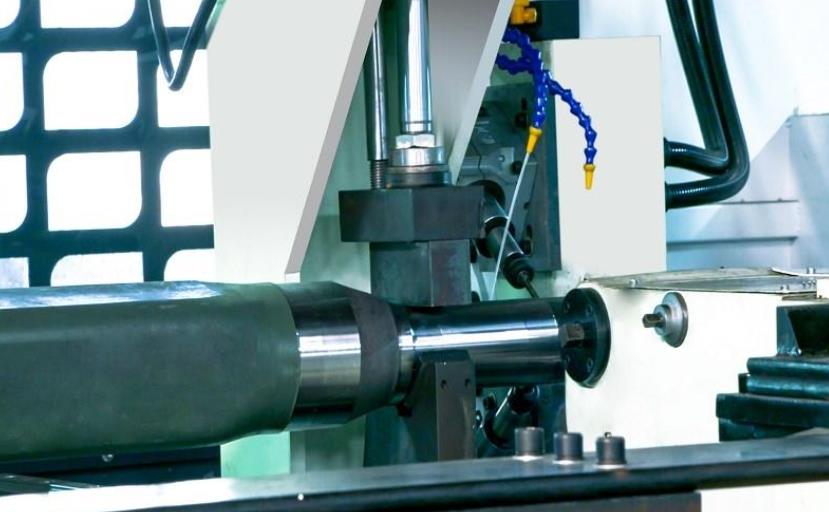

Ren Director also made a detailed introduction to us on each production link. Starting from the initial blanking, a qualified Daro axle has to go through 15 processes in the production and manufacture. Including raw material cutting, hot rolling, shaft head processing, high precision shaft tube forming, automatic medium frequency quenching, integral shaft tube heat treatment, sand blasting rust removal, online alignment, CNC precision grinding, medium frequency induction treatment, secondary finishing, shaft tube comprehensive testing, automatic gas protection welding, paint + electrophoresis, finished product assembly. If the axle is of special size, it needs to add 2 more precision grinding, so that the product produced can fully meet the standards in terms of comprehensive mechanical properties such as stiffness, toughness, wear resistance and fatigue resistance.

Such a complicated and precise production process, each of the Daro bridge has to go through.

Not only that, after the finished product assembly is completed, it also needs to go through online and offline dual quality testing. After passing the ultimate performance test of the test workshop, it can enter the market smoothly.

Director Ren said that at present, Daro Group is preparing to launch a batch of new quality testing instruments, investment in 25 million, only after the production of instruments can be installed. With this batch of new quality inspection instruments, the efficiency of online testing of products will be greatly improved. Moreover, the new quality inspection instruments are fully integrated into the existing production line. After each processing procedure, online quality inspection is required, and only when the standards are fully met can they be entered into the system and entered into the next production procedure. Fully prevent unqualified products from entering the market.

Real price shows strong strength

In contrast to the practice of adhering to reliable quality and never backsliding, Daiong Group also has its own insistence on product price.

In the current axle market, the polarization is more serious, one side is reliable quality but the price is very expensive, on the other side is cheap price but the quality is worrying. The Daiong Bridge is a special case. Different from other brands, Daro Group has never relied on its own axle quality to sit on the starting price or add moisture to the price. Since entering the market for 20 years, Daro has always insisted on giving back to users with the most reasonable price.

According to Mr. Zhang, the chairman of the board of Directors, Daro Group has gone through a lot of ups and downs from its initial establishment to now. Without the trust and support of all the friends, Daro could not have developed today. As the saying goes, "live a real life and do things honestly", no matter how the industry develops, no matter how the market changes, Daro Group should stick to integrity and gratitude, not adulterate the price, build a cost-effective axle, so that customers can afford to use more.

"To build a world-class commercial vehicle axle brand, to be the champion and innovator of China's machinery manufacturing industry" is the corporate mission of Daro Group, which is also the direction of Daro Group in the past, present and future. Today, the sales network of Daro Axle has spread throughout the country and exported to more than 50 countries and regions in Europe, America, the Middle East and Southeast Asia. In the future, we believe that with the international quality, fair and unadulterated price, persistent innovation and sincere attitude and service, Daro will eventually become the backbone of the quality of the great country, and become a leading brand in the axle industry at home and abroad.