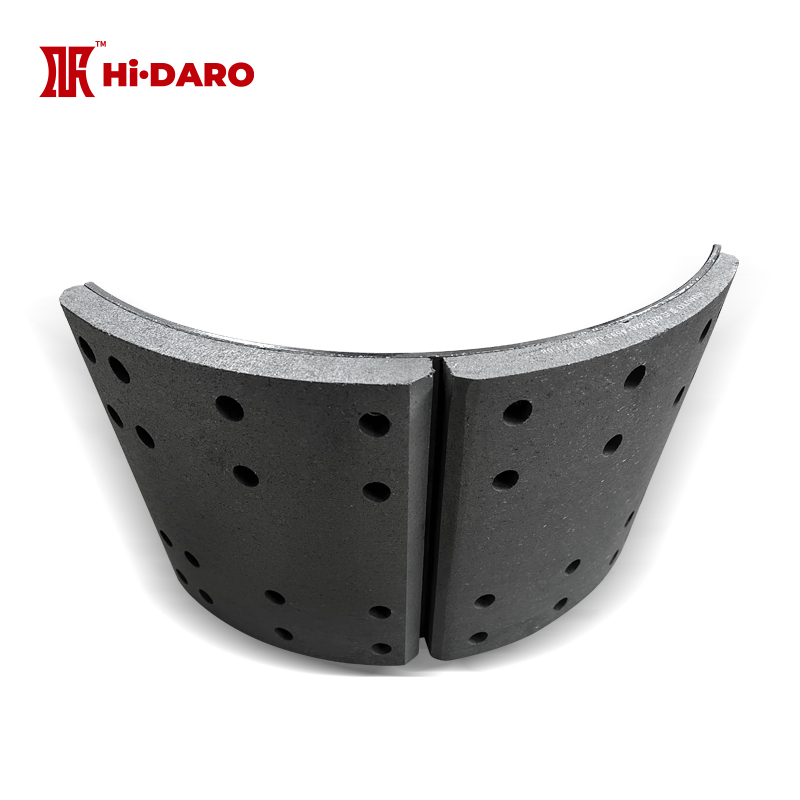

Faster heat dissipation and stable braking Brake pads for trailers

Brake pads for trailers sold by DARO Group are special for cargo transport vehicles, faster heat dissipation, sensitive braking, safety and stability, wear resistance. Stable friction performance, low wear, low high temperature decline, small wear to the brake drum. Choose high-quality materials, from material selection to processing, strictly control quality inspection, to ensure product quality. Advanced manufacturing technology, nitpicking details, product safety and reliability. Withstand high load, high friction coefficient, more stable braking effect, suitable for commercial models.

Texture of material:Asbestos free

Weight:1kg or 1.5kg

Colour:Grey cast iron

Supporting relationship:Original factory

Lining hardness:Standard

Products Description

DARO's Brake pads for trailers at wholesale prices:

1, high friction coefficient: this is a key factor in determining the size of brake pad braking force. Too low friction coefficient will lead to poor braking performance, weakness, and too long braking distance, while too high friction coefficient will cause wheel lock, direction loss and other problems.

2, good high temperature resistance: brake pads will produce high temperature when working. Poor quality brake pads may decrease the coefficient of friction and even brake collapse at high temperature, which is extremely dangerous.

3, the perfect match trailer: the new brake pads may take a while to break in. If there is brake jitter, abnormal sound, odor and other phenomena, it may be because of the suitability and matching degree of the brake pads.

4, efficient wear resistance: good wear resistance brake pads long service life.

Consider the following factors when choosing Brake pads for trailers:

1. Type and use of trailer. Different types of trailers have different needs for brake pads during use. For example, light trucks and general commercial vehicles are suitable for using organic brake pads, medium trucks and heavy commercial vehicles are suitable for using semi-metal brake pads, and high performance trucks and commercial vehicles are suitable for using ceramic brake pads.

2. Focus on braking performance and safety. According to your braking performance needs, choose the appropriate brake pads. For example, if you need higher braking effect and short braking distance, ceramic brake pads are a good choice. However, it is important to note that ceramic brake pads may cause greater wear on the brake disc.

3. Consider budget and longevity. Different types of brake pads have different prices and service life. The price of organic brake pads is low, but the life is relatively short; Semi-metal brake pad price moderate, long life; Ceramic brake pads are more expensive but last longer. Therefore, there are trade-offs based on budget and needs.

4. Refer to manufacturer's recommendations. The most important thing is to follow the recommendations and specifications of the truck manufacturer. Manufacturers usually provide recommended brake pad types and specifications, and you can refer to these recommendations to choose the most suitable brake pad.

Shandong DARO Machinery Co., Ltd. is a company focusing on the development and manufacturing of commercial vehicle Bridges and parts, headquartered in Liangshan, Shandong Province. The company promotes development with science and technology, has independent research and development capabilities, and further promotes intelligent production. Its products include trailer axle, axle assembly, special axle, trailer accessories and other series, and won the ISO9001 quality management system certification, was rated as high-tech enterprises in Shandong Province.