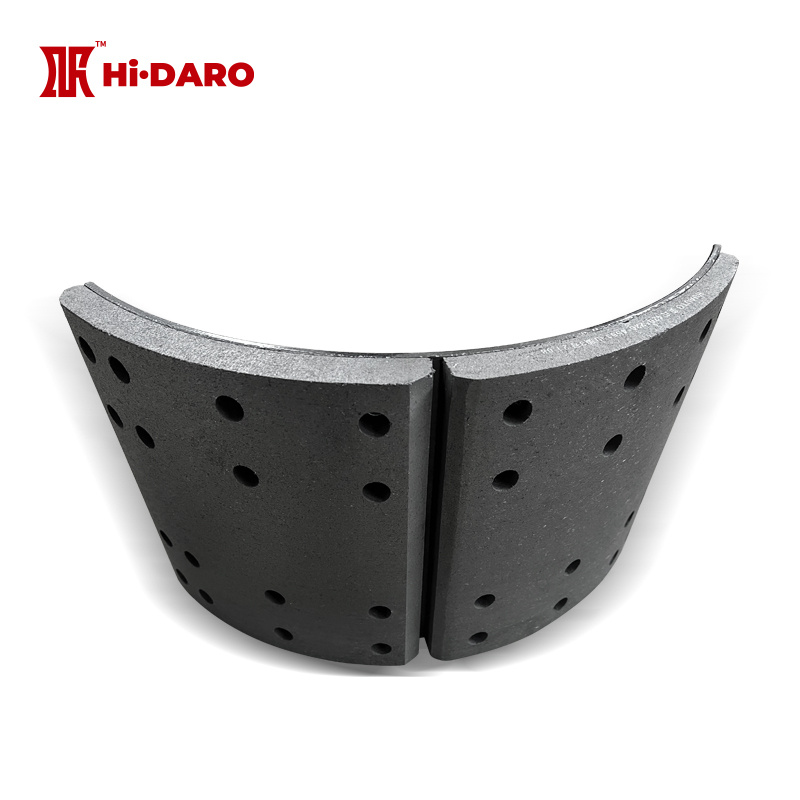

Products DescriptionCarefully chosen material——Selected excessive first-rate uncooked materials, brake shoe repair kits first-rate pass, secure performance, lengthy carrier life, really worth purchasing.Size standard—— Source manufacturers, manufacturing method in strict accordance with the trendy implementation, uniform size, enhance the utility accuracy.Quality stability——The product has exact tension and toughness, brake shoe repair kits anti-aging, anti-corrosio

Contact Now

Products DescriptionThermal attenuation resistance - excellent thermal stability.

Contact Now

Products DescriptionTrailer axle dedicated Brake Shoe is designed to fully integrate the characteristics of the use of semi-trailer axle, higher strength, high hardness chamfered inserts, frequent braking is not easy to deformation.

Contact Now

Products DescriptionOne piece format axleImprove the ordinary mechanical overall performance of the axleGood fatigue resistance and toughnessHigh machining accuracyBetter match of brake shoe and brake drumThe braking pressure is stable, and the phenomena such as brake jerk and eccentric put on are eradicatedModelMax.

Contact Now

Products DescriptionAdvanced manufacturing process, Brake Pad detail nitpicking, to ensure product safety and reliability.Bear high load, high friction coefficient, more stable braking effect, suitable for commercial models.Select high quality materials, from material selection to processing, strict quality control, to ensure product quality.Faster warmth dissipation and touchy brakingTrailer specific brake is stable, secure and stable, put on resistance and constructing resistanceStable friction performance, low wear, low e

Contact Now

Products DescriptionGood heat dissipation, high roundness, Brake Hub high speed balance, reduce hub wear.Denser low pressure casting process, with T6 heat treatment, not easy to deformation.Impact resistance melting, structure strengthening design, stronger product bearing capacity.Selected lightweight materials, lighter hub weight, minimize gasoline consumption.Good warmness dissipation, excessive roundness, excessive velocity balance, decrease hub wear.Denser low stress casting process, with T6 warmth&n

Contact Now

Products DescriptionOne piece design axle of Trailer axles and springs Improve the overall mechanical performance of the axleGood fatigue resistance and toughnessHigh machining accuracyBetter fit of brake shoe and brake drumThe braking force is stable, and the phenomena such as brake jerk and eccentric wear are eliminatedModelMax.

Contact Now

Products DescriptionBraked trailer axles Strong one-piece or welded axle head, exceeding the industry standard for hardness and tensile strength. Stable and reliable brake system with non-absestos brake linings.Higher machining accuracy - higher adhesion between the brake shoe and the brake drum, more stable output, and elimination of brake sticking, stumbling, and eccentric wear.ModelMax.

Contact Now

Products DescriptionDARO 10 ton trailer axles,the structure is more advanced, the braking response speed and effect are improved, and various suspensions can be flexibly matched. The product utilization rate is high, and it is cost-effective. The product design fully conforms to industry standards, with universal accessories and convenient maintenance. The brake shoe and brake drum have a higher fit degree and a more stable output, eliminating brake sticking, jerkiness, and eccentric wear. Through strict limit performance testing, it can adapt to complex usage environments.ModelMax.

Contact Now

Products DescriptionDARO 11T braked trailer axles,adopting a new optimized design, lightweight without sacrificing strength, flexible matching of various suspensions, high product utilization, and cost-effective. The brake shoe and brake drum have a higher fit and a smoother output, eliminating brake sticking, jerkiness, and eccentric wear. Using a special paint baking process, the corrosion resistance is improved by four times, and the protective force is greatly improved.ModelMax.

Contact Now

Products DescriptionDARO disc brake trailer axles:Easy maintenance: the brake pads of the disc axle are directly outside, you can see the brake pads or other structures very intuitively, and you can see whether you need to maintain the axle without disassembling it, if you need to maintain it, you only need to replace the brake pads.Light weight and strong thermal attenuation ability: disc axle banned 360° brake drum, the weight has been greatly improved; At the same time, after the installation of the disc axle, there is no need to install the water sprinkling device, which can further increa

Contact Now

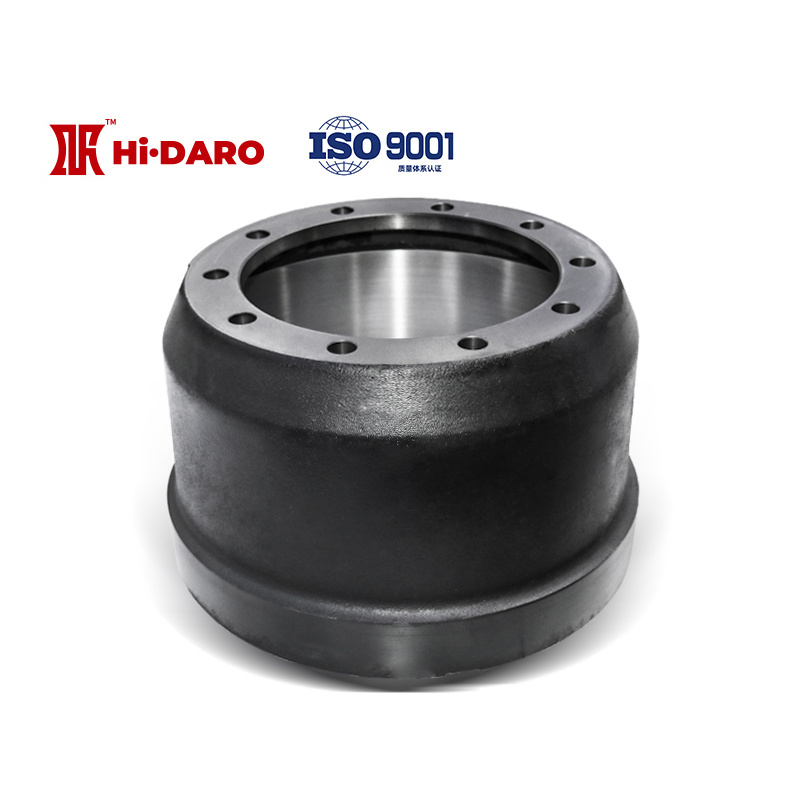

Products DescriptionThe trailer brake drum has reliable quality, faster heat conduction, higher wear resistance, heat resistance, heat dissipation and heat capacity.

Contact Now

Products DescriptionDARO sold 16T Brake pads for trailers selected high-quality raw materials, from material selection to processing are strictly controlled quality inspection. Using advanced manufacturing process, nit-picky details, with stable friction performance, low wear, low high temperature decline, small wear to the brake drum, to ensure product safety and reliability.

Contact Now

Products DescriptionSelected raw materials - the use of lighter weight high-strength alloy raw materials to reduce the weight of the truck Brake Drum product.Mature process - heat treatment and tempering, stronger wear resistance, good fit with brake shoes, improve driving safety.Reliable quality - faster thermal conductivity, higher wear resistance, heat resistance, heat dissipation and heat capacity.Authoritative quality inspection - assembly line production and assembly, individual inspection and warehousing, stable and reliable quality.The use of global superior forging technology, to

Contact Now

Products DescriptionThe Heavy duty trailer brake camshaft produced and bought by using DARO Group typically consists of a CAM and a shaft rod, and the CAM is linked with the shaft rod. The longitudinal part is a center-symmetric S-shape, and the two outer arcs of the S-shape are the involute traces of the core concentric circles of the CAM.

Contact Now

Products DescriptionBrake is one of the most frequently used parts of the vehicle. The performance of the brake pad plays a decisive role in the safety of the vehicle. Trailer drum brake pads produced by DARO are special for trailers.

Contact Now

Products DescriptionDARO's Brake pads for trailers at wholesale prices:1, high friction coefficient: this is a key factor in determining the size of brake pad braking force. Too low friction coefficient will lead to poor braking performance, weakness, and too long braking distance, while too high friction coefficient will cause wheel lock, direction loss and other problems.2, good high temperature resistance: brake pads will produce high temperature when working.

Contact Now

Products DescriptionTrailer axle parts produced by DARO Group are specially designed and built for trailer axles. Its Brake Shoe products bear high load, have high friction coefficient and more stable braking effect, and are suitable for commercial models. Preferably high-quality materials, from material selection to processing, strict control of quality inspection, to ensure product quality, its main role is to friction vehicles, to slow down or stop the vehicle. When selecting brake pads, it is necessary to select the right brand and model to ensure its suitability with the vehicle.

Contact Now

Products DescriptionTrailer axle brake Slack Adjuster is produced by a strong supplier and has been supplied domestically for more than ten years. It is exported to Southeast Asia, Europe, the Americas, and other regions with rich industry experience. The surface has been galvanized, with strong rust resistance, extended product service life, high precision, high strength, and suitable for trailer use.The Trailer axle brake Slack Adjuster belongs to the manual adjustment arm, which is used to manually adjust the brake clearance.

Contact Now

Products DescriptionDARO truck trailer brake pads have high wear, high temperature and corrosion resistance to ensure reliable braking capability under extremely high friction and temperature, fast heat dissipation, sensitive braking, low wear and low high temperature decay. Advanced manufacturing technology, high product precision, stable quality, from material selection to processing, strict control of quality inspection, to ensure product quality.The performance of brake pads is a key factor to measure its quality.

Contact Now

Products DescriptionDARO disc brake trailer axle:Integrated alloy brake disc, made by special technology, wear resistance, crack resistance, efficient heat dissipation.Special high strength bearings for trailers, effectively extend the service life.Locally strengthened square axial beam, large section coefficient, strong torsional and bending resistance.Integral heat treatment technology, improve the overall mechanical properties of the axle, good fatigue toughness.Braking is more sensitive and stable, and braking with ABS and EBS system is safer.ModelOffset(mm)Axle loadBrake(mm)Wheels Install

Contact Now

Products DescriptionThe DARO trailer axle with disc brake has a lighter weight, and the 360° brake drum is banned, which greatly improves the weight. At the same time, after the installation of the disc axle, there is no need to install the water sprinkling device, which can further increase the load of the vehicle.

Contact Now

Products DescriptionDARO trailer axle Brake Drum:Select raw materials -——Using lighter weight high-strength alloy raw materials to reduce product weight.Mature process -——heat treatment and tempering, better wear resistance, good fit with brake shoes, improve driving safety.Reliable quality —— faster heat conduction, higher wear resistance, heat resistance, heat dissipation and heat capacity.Authoritative quality inspection -——assembly line production, single inspection out of the warehouse, stable and reliable quality.DARO trailer axle Brake Drum is suitable for 13T-16T drum axle.

Contact Now

Products Description10000lbs trailer axle with electromagnetic brake pays attention to real materials in the selection of materials, 20Mn2 high-strength alloy seamless steel pipe, with better tensile strength, yield strength and impact toughness, equipped with national standard automatic production line, and authoritative quality inspection, the quality of finished products is trustworthy.

Contact Now