Products DescriptionDARO sold 16T Brake pads for trailers selected high-quality raw materials, from material selection to processing are strictly controlled quality inspection. Using advanced manufacturing process, nit-picky details, with stable friction performance, low wear, low high temperature decline, small wear to the brake drum, to ensure product safety and reliability.

Contact Now

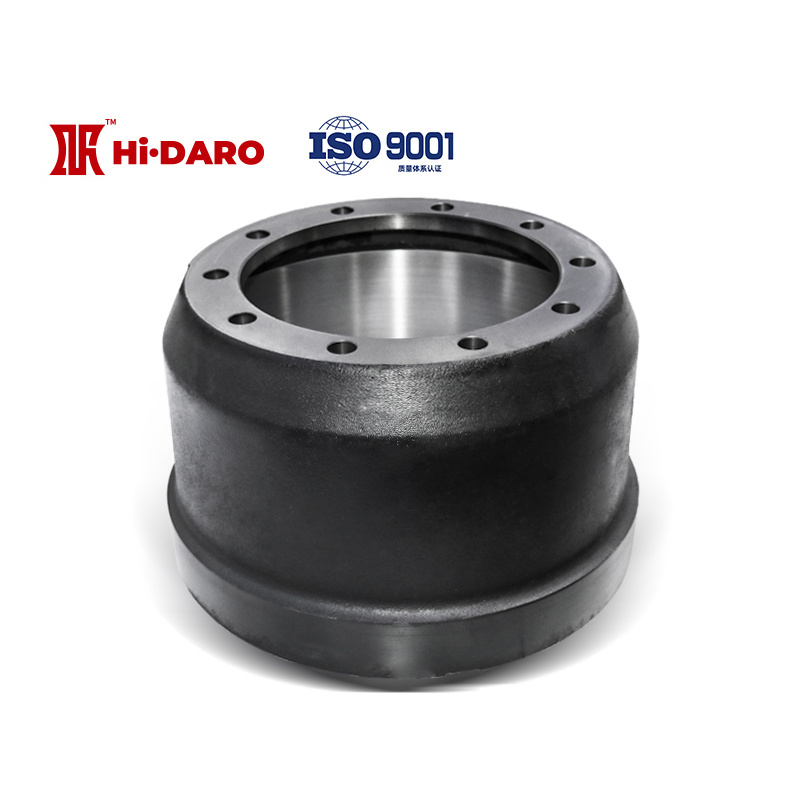

Products DescriptionDARO trailer axle Brake Drum:Select raw materials -——Using lighter weight high-strength alloy raw materials to reduce product weight.Mature process -——heat treatment and tempering, better wear resistance, good fit with brake shoes, improve driving safety.Reliable quality —— faster heat conduction, higher wear resistance, heat resistance, heat dissipation and heat capacity.Authoritative quality inspection -——assembly line production, single inspection out of the warehouse, stable and reliable quality.DARO trailer axle Brake Drum is suitable for 13T-16T drum axle.

Contact Now

Products DescriptionDARO Hot Sale American Type single trailer axle is the most widely used axle in the market. The standard axle can carry 13t, the light axle can carry 9t, 10t and 12t, and the heavy axle can carry 14t, 16t, 20t and 25t. It can be customized according to the needs of users. Its biggest advantages are cost-effective, affordable, excellent performance, accessories industry general, easy to buy good matching, save worry and effort.ModelMax.

Contact Now

Products DescriptionDARO's American style Axle Beam sold at wholesale price, is one of the few products in the market with good quality, discounted prices, and high cost-effectiveness. After entering the market for 20 years, it has won widespread recognition from many customers due to its stable quality and performance. It inherits the strong load-bearing, durable, and resistant characteristics of classic American style, while also possessing advantages such as convenient maintenance, simple maintenance, and easy replacement of accessories, with a high market coverage.ModelMax.

Contact Now

Products DescriptionDARO 13T American type Trailer axle Beam is made of 20Mn2 high-strength alloy seamless steel pipe with standard wall thickness of 11mm and diameter width of 150*150mm. Integrated hot rolling molding process eliminates manual welding, and has stronger bending and torsional resistance and load-bearing capacity. Ensure the efficient operation of vehicles for a long time.ModelMax.

Contact Now

Products DescriptionDARO American type utility trailer axle beam:High load-bearing capacity: American style axles are made of high-strength steel or alloy steel, which have undergone precision machining and heat treatment, and have high load-bearing capacity. It can withstand large weight and pressure, is not prone to deformation and bending, ensuring the stability and safety of vehicle operation.Long service life: Due to the high quality assurance of American axle materials and manufacturing processes, their service life is relatively long.

Contact Now

Products DescriptionThe design of 12T american style lowbed trailer axle produced by DARO Group fully considers the transportation demand of low flat semi-trailer. It has smaller ground height, lower center of gravity height, and better transportation stability, which facilitates loading and unloading of heavy goods and improves the passability of vehicles on high-limited road sections. Double-layer anti-rust paint treatment, double moisture, corrosion, oxidation resistance, can better isolate the external erosion, protect the axle.ModelMax.

Contact Now

Products DescriptionThe difference between American type trailer axle tube produced by DARO Group and German axle tube mainly lies in the axle head. The axle head and shaft body of American type trailer axle tube are shaped from a 20Mn2 seamless steel pipe. There is no need for manual welding in the middle, so the connection is more natural and load-bearing. In addition, the axle head has higher bit wall thickness and is more durable and resistant. Therefore, compared with German axle tube, American type trailer axle tube has better load-bearing capacity.ModelMax.

Contact Now

Products DescriptionSpoke hub trailer axle:1、The use of unit design, to maintain good sealing under high-speed operation, maintain the internal cleaning of the parts.2、Multi-layer sealing structure, plus sealing sleeve, isolation of pollution, prevent grease overflow.3、With higher stiffness and accuracy, maintain safe operation and extend service life.4、The maintenance process is simplified, the replacement is easier, the user's downtime is reduced, and the operation efficiency is improved.5、The toughness and elasticity of the product are greatly improved, which can effectively buffer and

Contact Now

Products DescriptionDARO German type axle tube tonnage covers 12T, 14T, 16T, 18T, wheel base 1840 and 1850, other specifications can be customized production. DARO's axle tube is made of high-strength 20Mn2 seamless steel pipe processing, strict and unified production standards, with multiple quality inspection methods, stable and reliable performance, 20 years into the market with many trailer plants, bridge plants, repair plants to establish a good relationship of cooperation.ModelMax.

Contact Now

Products Description72 inch spring center trailer axle is a classic American axle suitable for all types of American axles. High strength seamless steel pipes are selected with excellent production technology. Adding a medium frequency quenching strengthening process makes the shaft head stronger, stronger, and more durable.ModelMax.

Contact Now

Products DescriptionHarbor freight trailer axle High cost performance: American axles are relatively low in price, and the investment cost is low for consumers.High reliability: The manufacturing process and materials of American-style axles are guaranteed to a certain extent, making them highly reliable during use.ModelMax.

Contact Now

Products DescriptionDARO American Style trailer axle adopts new optimized design, which is lighter in weight than traditional American axle and achieves lightweight without sacrificing strength. The product design fully conforms to industry standards, the accessories are universal, the maintenance is convenient, and the trailer has passed strict ultimate performance test, with strong environmental adaptability. Can adapt to complex use environment.ModelMax.

Contact Now

Products DescriptionHigh elasticity—— Leaf Spring For American Type Suspension Parts are highly elastic, able to withstand a large number of deformations and return to their original shape and size when external forces are removed.High load capacity—— Due to the high stiffness of Leaf Spring For American Type Suspension Parts, it can withstand a large amount of load without permanent deformation.Good stability—— Leaf Spring For American Type Suspension Parts have good stability and will not change greatly with changes in the external environment.Corrosion resistance—— Leaf

Contact Now

Products DescriptionSquare trailer axle have high cost performance, relatively low acquisition costs, good heavy-duty performance, large inventory, and more convenient maintenance; The disadvantages are heavy weight and relatively high maintenance frequency. Generally, American type axles can be widely used in various general cargo transportation conditionsModelMax.

Contact Now

Products DescriptionThe DARO Group's german type trailer axles include 12T, 13T, 14T, 16T and 18T tonnage, which can be customized to meet customer requirements. DARO has its own factory, and the entire production process is subject to unified and strict quality control, from the internal mechanical properties of steel to the external dimensional accuracy, fully in line with national standards. The quality inspection process starts from raw materials, covering every link of design, production and testing.

Contact Now

Products DescriptionDARO trailer axle replacement adopts a new American axle design, which is integrated heat treatment and forming, eliminating manual welding. The axle head and axle body are built from a steel pipe, which has stronger load-bearing capacity. Fifteen national standard process Settings, online and offline double quality inspection, production accuracy strict standards; Product design fully in line with industry standards, universal accessories, easy maintenance; No bending and deformation under high strength, ensuring long-term and efficient operation of vehicles.ModelMax.

Contact Now

Products DescriptionDARO Group sells heavy duty trailer axles at wholesale price with complete models, rich styles, tonnage covering 13t, 14t, 15t, 16t, 20t, 25t, etc., which can meet the different needs of customers. Special sizes can be customized, and "integrated" heat treatment molding process is adopted. The shaft head is integrated with the shaft tube, avoiding subsequent manual welding, reducing welding deformation, improving strength and ensuring the accuracy of the axle.ModelMax.

Contact Now

Products DescriptionDARO american type trailer spindle and hub is a trailer axle with the highest coverage on the market, strong braking force, stable bearing capacity, affordable price, and easy maintenance, which is favored by many owners. After more than a dozen production processes, unified and strict production supervision, authoritative and credible quality inspection methods, quality can stand the test of the market.ModelMax.

Contact Now

Products DescriptionThe semi trailer axle assembly head and axle tube of an American type axle are integrated and made from a single steel pipe. The two are naturally connected. There is no manual welding between the axle head and the axle tube, fully avoiding welding deformation. The strength of the natural connection is high, and the ability to withstand heavy loads is also stronger.ModelMax.

Contact Now

Products DescriptionDARO trailer suspensionuse silicon manganese spring steel, with higher strength, elasticity, and hardenability.Simpler structural design, convenient installation and use, more convenient maintenance and replacement, and high cost-effectiveness.Ensures high strength while improving product toughness, with significant strengthening and toughening effects, and better comprehensive mechanical properties.Suspension ModelA1 (mm)A1* (mm)A2 (mm)A2* (mm)A3 (mm)A3* (mm)H (mm)Carrying Capacity(kg)DR13.300138034037033036532513513000*3DR13.300240036039035038534515513000*3DR13.3003430390

Contact Now

Products DescriptionDARO German Style Independent axles for trailers,it belongs to a kind of drum axle, the advantage is more inclined to lightweight and long-term, weight than the American drum axle is lighter, can save fuel, design of high temperature resistance, small tire damage, maintenance cycle has been extended to a certain extent.ModelMax.

Contact Now

Products DescriptionThe american type Independent trailer axle produced by DARO Group adopts 20Mn2 high-strength alloy seamless steel pipe as the raw material, with both strength and toughness reaching the standard and stronger load-bearing capacity. Brake drum, wheel hub, bearing, brake pads, bolts and other parts are used in the industry's leading brands, stable and reliable quality. Entering the market for more than 20 years, customers are highly praised.ModelMax.

Contact Now

Products DescriptionDARO American Style Lorry trailer axles is relatively affordable, has a simple structure, and its accessories are commonly used in the industry. It is easy to buy and match, and maintenance is more convenient. The 360 ° sealed brake drum has a large braking friction area, stronger braking force, and more sufficient braking force,Is the most widely used axle type on semi trailers.ModelMax.

Contact Now